Preparing method and application of lithium ion battery cathode material selenium ferrous sulfide

A lithium ion battery and ferrous sulfide technology, applied in the field of electrochemistry, can solve the problems of lack of ferrous selenium sulfide negative electrode material, etc., and achieve the effects of high rate performance, simple operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

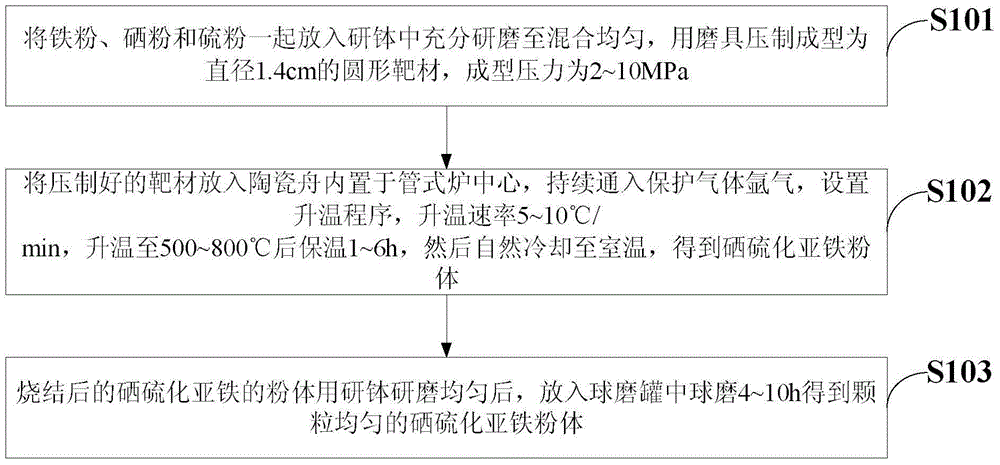

[0017] Such as figure 1 As shown, the preparation method of the negative electrode material ferrous selenium sulfide of the embodiment of the present invention comprises the following steps:

[0018] S101: Put the iron powder, selenium powder and sulfur powder together into a mortar and grind them until they are evenly mixed, and press them with a grinding tool to form a circular target with a diameter of 1.4 cm, and the forming pressure is 2-10 MPa;

[0019] S102: Put the pressed target material into the ceramic boat and put it in the center of the tube furnace, continuously feed the protective gas argon, set the temperature rise program, the temperature rise rate is 5-10°C / min, heat up to 500-800°C and then keep it warm for 1~ 6h, then naturally cooled to room temperature to obtain ferrous selenium sulfide powder;

[0020] S103: After the sintered ferrous selenium sulfide powder is uniformly ground with a mortar, it is put into a ball mill jar and ball milled for 4-10 hour...

Embodiment 1

[0032] (1) Iron powder, selenium powder and sulfur powder mixed pressing target:

[0033] Put the iron powder, selenium powder and sulfur powder together into the mortar and grind them until they are evenly mixed, and press them into a circular target with a diameter of 1.4 with a molding pressure of 6 MPa;

[0034] (2) Under an argon protective atmosphere, sinter ferrous selenium sulfide with a tube furnace:

[0035] Put the pressed target into the ceramic boat and put it in the center of the tube furnace, continuously feed the protective gas argon, set the heating program, the heating rate is 5°C / min, heat it to 700°C and keep it for 2h, and then cool it down to room temperature naturally. Obtain ferrous selenium sulfide powder;

[0036] (3) the ferrous selenium sulfide powder ball mill of gained:

[0037] After the powder of the sintered ferrous selenium sulfide is uniformly ground with a mortar, it is put into a ball mill pot and ball milled for 6 hours to obtain a unifo...

Embodiment 2

[0041] (1) Iron powder, selenium powder and sulfur powder mixed pressing target:

[0042] Put the iron powder, selenium powder and sulfur powder together into the mortar and grind them until they are evenly mixed, and press them into a circular target with a diameter of 1.4 with a molding pressure of 6 MPa;

[0043] (2) Under an argon protective atmosphere, sinter ferrous selenium sulfide with a tube furnace:

[0044] Put the pressed target into the ceramic boat and put it in the center of the tube furnace, continuously feed the protective gas argon, set the heating program, the heating rate is 5°C / min, heat it to 700°C and keep it for 2h, and then cool it down to room temperature naturally. Obtain ferrous selenium sulfide powder;

[0045] (3) the ferrous selenium sulfide powder ball mill of gained

[0046] After the powder of the sintered ferrous selenium sulfide is uniformly ground with a mortar, it is put into a ball mill pot and ball milled for 6 hours to obtain a unifor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com