Method for the degradation of keratin and use of the keratin hydrolysate produced

A technology for hydrolyzate and keratin, applied in the field of degrading keratin or preparing keratin hydrolyzate, which can solve the problems of cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

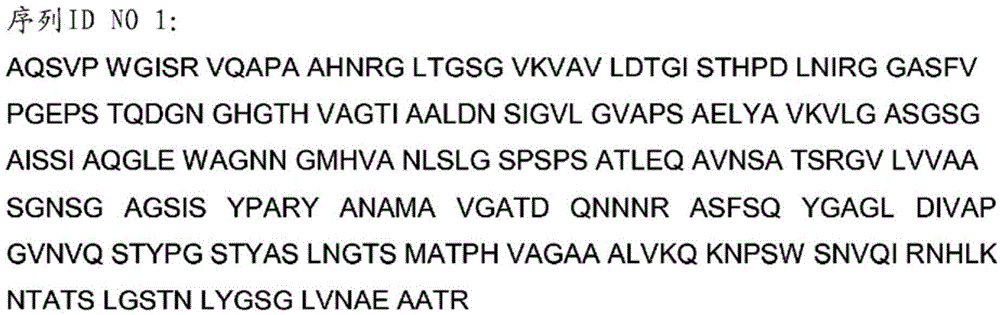

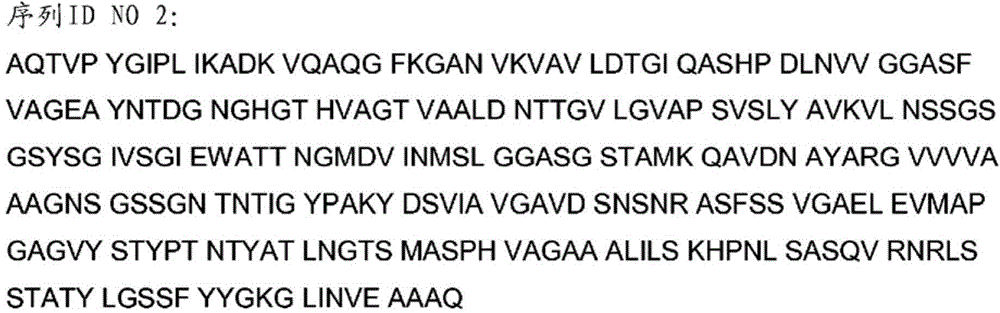

[0212] Nucleotide sequence preparation

[0213] A nucleotide sequence encoding a protein having specific properties as defined herein or a protein suitable for modification may be identified and / or isolated and / or purified from any cell or organism producing said protein. Various methods are well known in the art of nucleotide sequence identification and / or isolation and / or purification. For example, once suitable sequences have been identified and / or isolated and / or purified, PCR amplification techniques can be used to prepare further sequences.

[0214] As another example, genomic DNA and / or cDNA libraries can be constructed using chromosomal DNA or messenger RNA from the organism producing the enzyme. If the amino acid sequence of the enzyme is known, labeled oligonucleotide probes can be synthesized and used to identify enzyme-encoding clones from genomic libraries prepared from the organism. Alternatively, a labeled oligonucleotide probe containing a sequence homologo...

example 1

[0389] To each of six 13 ml plastic tubes was added 100 mg ground chicken feathers (rachis and hollow shafts were ground to be shorter than 0.5 cm), 5 mg sodium bisulfite and 65 microliters of Protex P. 12 ml of tap water at pH 7.90 was added to tubes 1-3, while 12 ml of tap water and sodium hydroxide were added to tubes 4-6 to reach a final concentration of 0.7 mM and degassed (bubbled with nitrogen). The tubes were tightly closed and then incubated for 16 h at 50°C with shaking at 130 rpm. The 6 tubes were then centrifuged at 4000 rpm and 0.2 ml of the supernatant from each sample was filtered through a 0.45 micron filter and 50 microliters of each filtrate was measured at 280 nm as an indicator of the released peptide (see below Table 1). As can be seen from the table below, peptide release was increased by 21% by degassing the reaction medium by bubbling nitrogen and adding sodium hydroxide to the reaction medium to a final concentration of 0.7 mM.

[0390] Table 1

...

example 2

[0393] For alkaline protease treatment, the reaction mixture contained 9 ml of water, 1 ml of tris-HCl (0.48M, pH 8.5), one chicken feather, 150 microliters of Protex 30L (available from DuPont Industrial Biosciences ApS)) and 20 mg reducing agent sodium bisulfite. The reaction mixture was incubated overnight (16 hours) at 50° C. with shaking at 100 rpm in a free-fall mixer. For peracetic acid treatment, following the protease reaction, the reaction mixture of Protex 30L treated feathers was centrifuged and the pellet was resuspended in peracetic acid (cat. no. 77240, Sigma-Aldrich company (Sigma-Aldrich), pure (purum), about 39% in acetic acid solution).

[0394] Table 2

[0395]

[0396] Results: It can be seen that the turbidity decreased from 0.738 to 0.04 with increasing peracetic acid concentration, indicating that the reaction mixture became clearer (lower absorbance at 600 nm). This is due to the oxidation and solubilization effect of peracetic acid on feather ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com