Insecticidal composition for preventing and controlling insect pests with piercing-sucking mouthparts

An insecticidal composition and a piercing-sucking technology are applied in the field of pesticides to achieve the effects of reducing ecological damage, high control efficiency and significant synergistic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

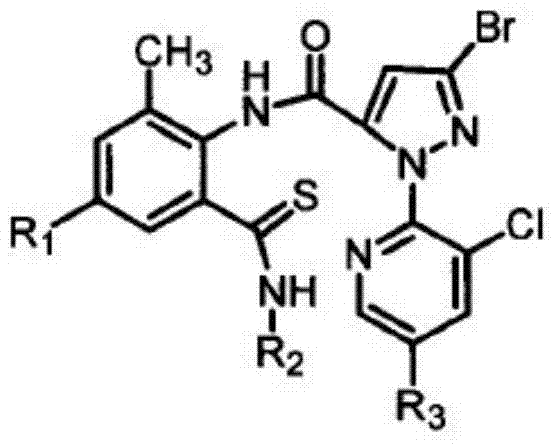

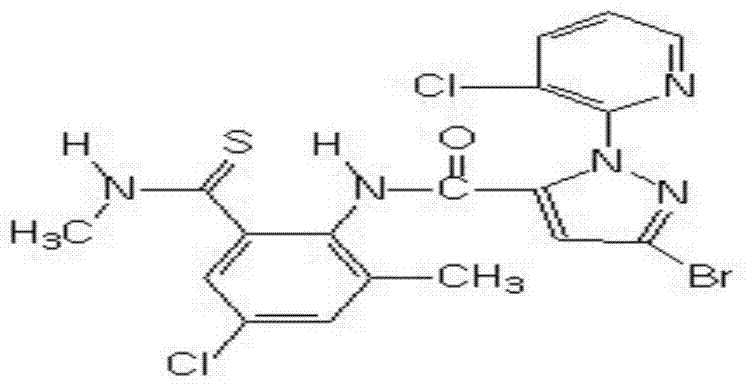

Image

Examples

Embodiment 1

[0044] Example 1: 33% thiobenzamide·pymetrozine suspending agent (10:1)

[0045] 33% active compound (composition of 30% thiobenzamide and 3% pymetrozine), alkylnaphthalene sulfonate 2%, fatty alcohol polyoxyethylene ether sulfate 1.3%, phenolsulfonic acid condensate sodium Salt 2%, glycerol 2%, butylparaben 0.2%, silicone 0.1%, water to make up to 100%, put into a high shear homogeneous emulsifier for high-speed shearing for 25 minutes, and then pump to sand Sand grinding in a mill for 90 minutes, and after filtration, a suspension containing 33% of the active compound was obtained.

Embodiment 2

[0046] Example 2: 31% thiobenzamide·pirimicarb suspending agent (30:1)

[0047] 31% active compound (composition of 30% thiobenzamide and 1% pirimicarb), alkylnaphthalene sulfonate 2.3%, acyl glutamate 2%, phenolsulfonic acid condensate sodium salt 1% , sodium methylnaphthalene sulfonate formaldehyde condensate 2%, epoxidized soybean oil 5%, glycerol 2%, silicone 0.1%, water to make up to 100%, put into a high-shear homogeneous emulsifier for high-speed shearing 25 minutes, then pumped to a sand mill for sand grinding for 90 minutes, and after filtration, a suspending agent containing 31% of the active compound was obtained.

Embodiment 3

[0048]Example 3: 30% thiobenzamide·isoprocarb suspending agent (2:1)

[0049] 30% active compound (composition of 20% thiobenzamide and 10% isoprecarb), alkylnaphthalene sulfonate 2.6%, acyl glutamate 2%, fatty alcohol polyoxyethylene ether sulfate 1 %, phenolsulfonic acid condensate sodium salt 1.0%, polymer polycarboxylate 2%, sodium starch octenyl succinate 2.4%, glycerol 2%, silicone defoamer 0.1%, deionized water 100%, put into a high-shear homogeneous emulsifier for high-speed shearing for 25 minutes, then pump to a sand mill for sand grinding for 90 minutes, and filter to obtain a suspending agent containing 30% of active compounds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com