Production method of black fungus top-quality drink for improving respiratory tract diseases

A technology of black fungus and respiratory tract, applied in the production field of black fungus agaric, to achieve the effect of improving respiratory diseases and related symptoms, simple operation and easy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

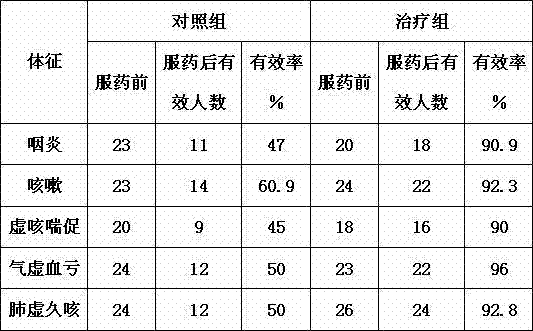

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A black fungus wine for improving respiratory diseases, characterized in that: it is made of the following raw materials: by weight: 40-50 parts of black fungus juice, 3-4 parts of honey, 5-6 parts of fructooligosaccharides, oligosaccharides 5~10 parts of xylose, 5~10 parts of resistant dextrin, 5~10 parts of maltodextrin, 0.01~0.02 parts of CMC-Na, 0.1~0.3 parts of citric acid, 0.03~0.05 parts of potassium sorbate, drinking water 100 copies.

[0032] Ratio by weight: 40-48 parts of black fungus juice, 4 parts of honey, 5 parts of fructo-oligosaccharide, 5-8 parts of xylo-oligosaccharide, 5-8 parts of resistant dextrin, 5-8 parts of maltodextrin, 0.02 parts of CMC-Na, 0.2 parts of citric acid, 0.04 parts of potassium sorbate, and 100 parts of drinking water.

[0033] Ratio by weight: 45 parts of black fungus juice, 4 parts of honey, 5 parts of fructo-oligosaccharide, 7 parts of xylo-oligosaccharide, 7 parts of resistant dextrin, 7 parts of maltodextrin, 0.02 part...

Embodiment 2

[0046] 1. Pretreatment of raw materials: remove impurities from black fungus raw materials, wash and set aside;

[0047] 2. Chopping and grinding: chop the cleaned black fungus and grind them;

[0048] 3. Enzymolysis: Add 0.3% xylanase by weight to the waste and crushed black fungus, adjust the pH value to 4.5, enzymolysis temperature is 45°C, and enzymolysis time is 6 hours;

[0049] 4. Juice production: add water 5 times its weight to the enzymatically hydrolyzed black fungus, stir evenly, and use the water extraction process to make black fungus juice;

[0050] 5. Homogenization: Homogenize the black fungus juice at a temperature of 85°C and a homogenization pressure of 20MPa to obtain black fungus pulp;

[0051] 6. Deployment: 45 parts by weight of black fungus juice, 4 parts of honey, 5 parts of fructo-oligosaccharides, 10 parts of xylo-oligosaccharides, 10 parts of resistant dextrin, 10 parts of maltodextrin, 0.1 part of citric acid, CMC-Na0 .01 part, 0.04 ...

Embodiment 3

[0057] 1. Pretreatment of raw materials: remove impurities from black fungus raw materials, wash and set aside;

[0058] 2. Chopping and grinding: chop the cleaned black fungus and grind them;

[0059] 3. Enzymolysis: Add 0.5% of its weight of plant hydrolytic enzyme to the waste and crushed black fungus, adjust the pH value to 4.5~5.0, enzymolysis temperature is 40°C, and enzymolysis time is 5 hours;

[0060] 4. Juice production: add water 5 times its weight to the enzymatically hydrolyzed black fungus, stir evenly, and use the water extraction process to make black fungus juice;

[0061] 5. Homogenization: Homogenize the black fungus juice at a temperature of 73°C and a homogenization pressure of 18MPa to obtain black fungus pulp;

[0062] 6. Preparation: 50 parts by weight of black fungus juice, 3 parts of honey, 5 parts of fructo-oligosaccharides, 5 parts of xylo-oligosaccharides, 10 parts of resistant dextrin, 10 parts of maltodextrin, 0.01 parts of CMC-Na, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com