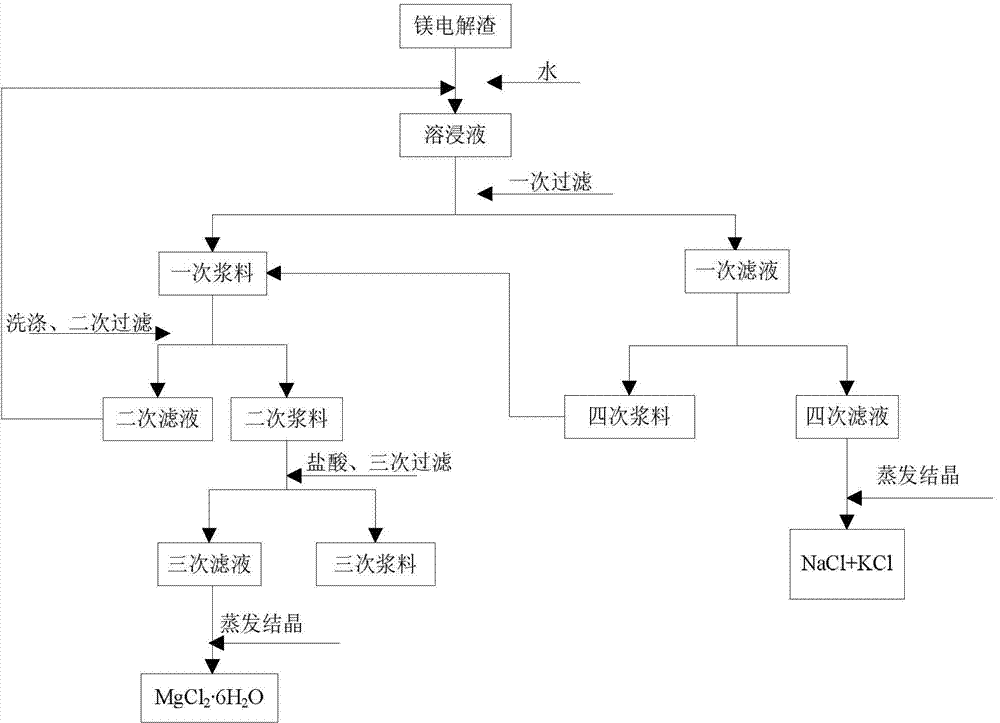

Method for separating potassium chloride, sodium chloride and magnesium chloride from magnesium electrolysis residues

A technology of magnesium electrolytic slag and potassium chloride, which is applied in the field of separating potassium chloride from sodium chloride and magnesium chloride, can solve the problems that carnallite cannot be directly used and is difficult to control, so as to realize recycling and reuse, and solve the problem of environment Risk, simple steps, effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] If the magnesium content is too high, potassium magnesium carnallite will be formed during the evaporation and crystallization process, which will affect the reuse of potassium chloride and sodium chloride mixed salt; in order to reduce the magnesium content in the filtrate, a decontamination agent is added to the filtrate to detect the presence of impurities in the filtrate. Calcium, magnesium content (table 1);

[0051] Table 1 Calcium and magnesium content in filtrate after adding impurity remover

[0052] Amount of impurity remover (g / l)

[0053] Therefore, the amount of impurity remover added is 5-10g / L.

Embodiment 2

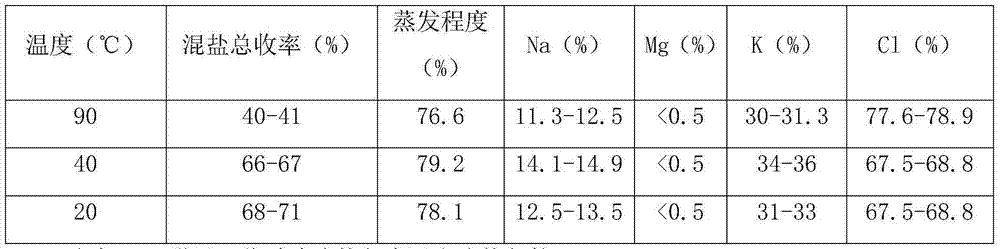

[0055] Considering production cost and equipment type selection, sodium chloride, the crystallization separation temperature of potassium chloride mixture are analyzed, and the results are shown in Table 2:

[0056]Table 2 The effect of crystallization temperature on yield and crystallization product components

[0057]

[0058] Choose around 40°C, at this time the volume of the filtrate is 5-7% of the volume of the leachate.

Embodiment 3

[0060] The concentration of hydrochloric acid added in the secondary slurry is studied, and the test results are shown in Table 3:

[0061] Table 3 Dissolution of different concentrations of hydrochloric acid

[0062] Hydrochloric acid concentration (%)

[0063] Therefore, the concentration of hydrochloric acid added in the secondary slurry is selected at 10-15%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com