Method for purifying and refining brassylic acid

A tridecanedioic acid and refining method technology, applied in the separation/purification of carboxylic acid compounds, carboxylate preparation, chemical instruments and methods, etc., can solve the problem of acetic acid and methanol being volatile, increasing the load of purification, and product yield. It can improve the purity, reduce the generation of salt, and improve the color and luster.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

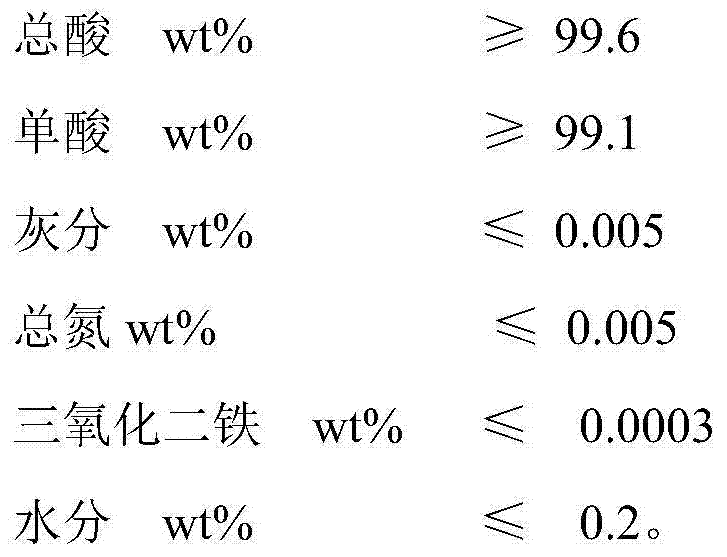

Embodiment 1

[0063] A kind of refining method of improving tridecanedioic acid purity and yield of the present invention comprises the following steps:

[0064] ①.. Adsorption decolorization

[0065] In the dissolution reactor, put 1000 parts by weight of deionized water, add 180 parts by weight of crude tridecanedioic acid in dry weight under stirring, add 110 parts by weight of sodium hydroxide aqueous solution with a mass concentration of 30.3%, and heat up to 100 ° C , the pH value is controlled between 6.0, after the material is completely dissolved, add 3 parts by weight of coconut shell-type activated carbon, and keep warm for 20 minutes for decolorization;

[0066] ②..oxidative decolorization

[0067] Filter the material treated in step ① while it is hot, rinse the filter cake with hot water at 90°C, put the filtrate and flushing liquid into the oxidation decolorization reaction kettle, raise the temperature to 98°C, and control it at 5~ Within 10 minutes, add hydrogen peroxide w...

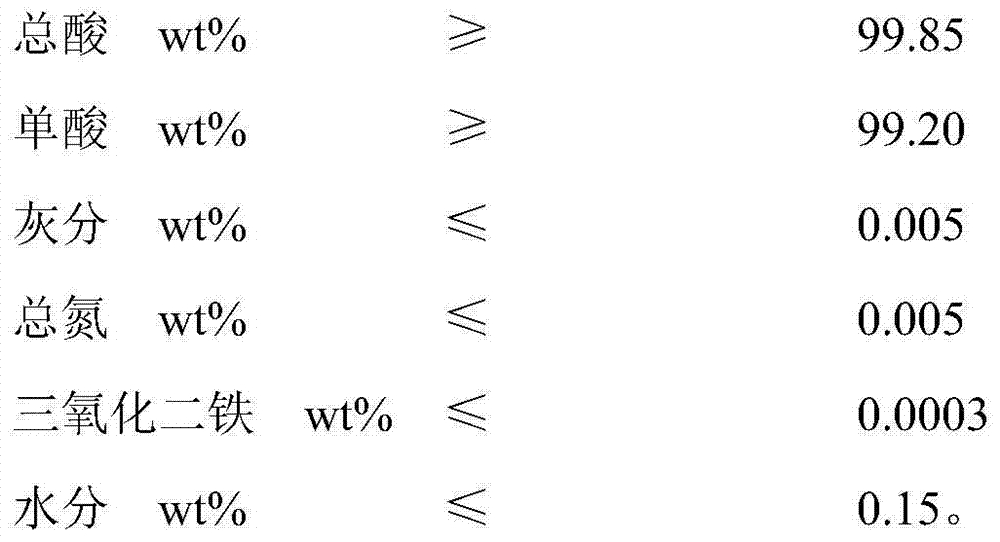

Embodiment 2

[0078] A kind of refining method of improving tridecanedioic acid purity and yield of the present invention comprises the following steps:

[0079] ①.. Adsorption decolorization

[0080] In the dissolution reactor, put 1000 parts by weight of deionized water, add 180 parts by weight of crude tridecanedioic acid in dry weight under stirring, add 110 parts by weight of sodium hydroxide aqueous solution with a mass concentration of 30.3%, and heat up to 101 ° C , the pH value is controlled between 6.1, after the material is completely dissolved, add 4 parts by weight of coconut shell-type activated carbon, and keep warm for 30 minutes for decolorization;

[0081] ②..oxidative decolorization

[0082] Filter the material treated in step ① while it is hot, rinse the filter cake with hot water at 85°C, put the filtrate and flushing liquid into the oxidation decolorization reaction kettle, raise the temperature to 99°C, and control it at 5~ Within 10 minutes, add hydrogen peroxide w...

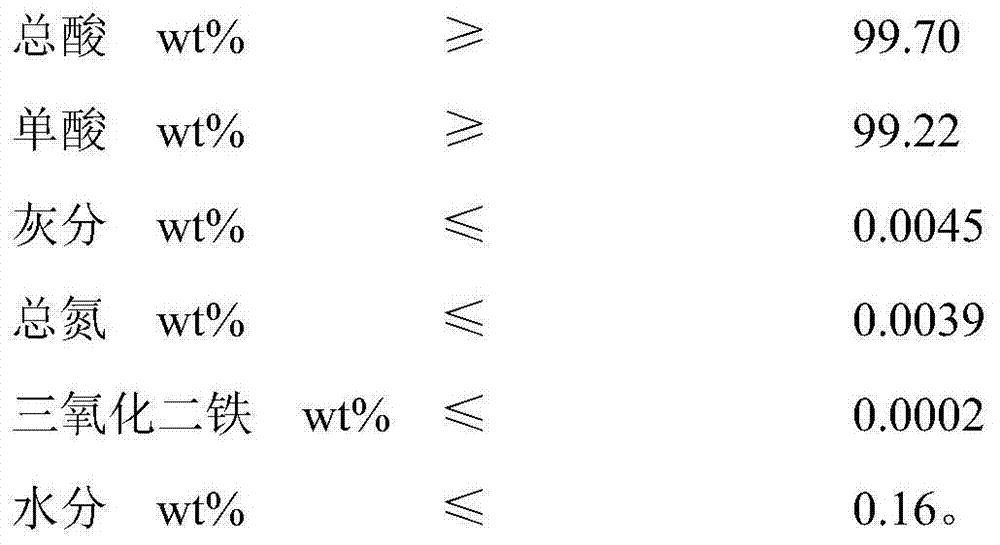

Embodiment 3

[0093] A kind of refining method of improving tridecanedioic acid purity and yield of the present invention comprises the following steps:

[0094] ①.. Adsorption decolorization

[0095] In the dissolution reactor, put 1000 parts by weight of deionized water, add 180 parts by weight of crude tridecanedioic acid in dry weight under stirring, add 110 parts by weight of sodium hydroxide aqueous solution with a mass concentration of 30.3%, and heat up to 102 ° C , the pH value is controlled between 6.2, after the material is completely dissolved, add 5 parts by weight of coconut shell-type activated carbon, and keep warm for 25 minutes for decolorization;

[0096] ②..oxidative decolorization

[0097] Filter the material treated in step ① while it is hot, rinse the filter cake with hot water at 88°C, put the filtrate and flushing liquid into the oxidation decolorization reaction kettle, raise the temperature to 100°C, and control the temperature at 5~ Within 10 minutes, add hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com