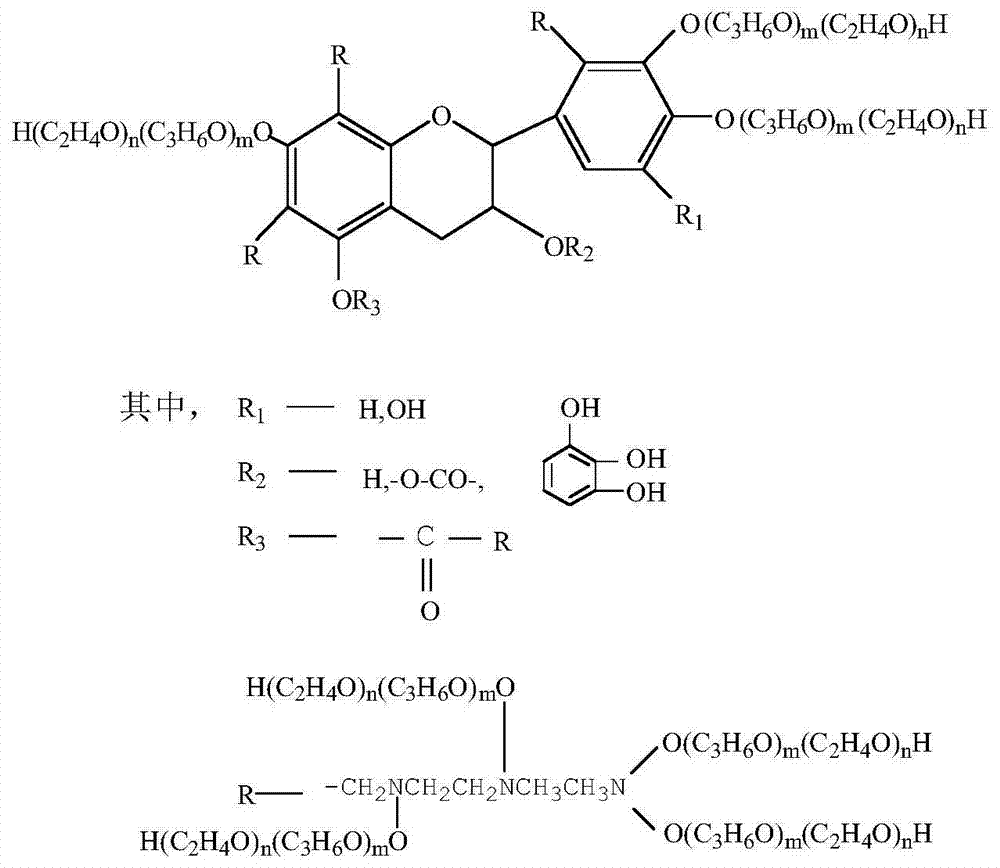

Novel broad-spectrum crude oil demulsifying agent and preparation method thereof

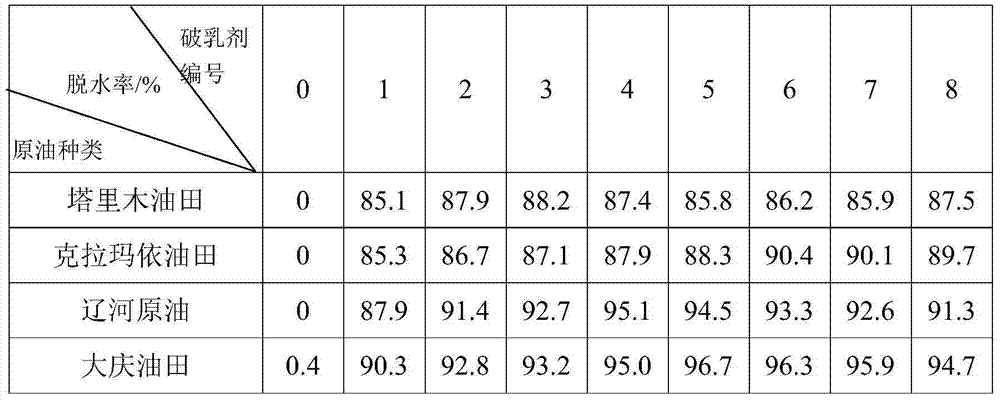

A crude oil demulsifier and demulsifier technology, which is applied in the direction of chemical dehydration/demulsification, etc., can solve the problems of inability to meet the needs of industrial production and high demulsification temperature, and achieve the effect of good demulsification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

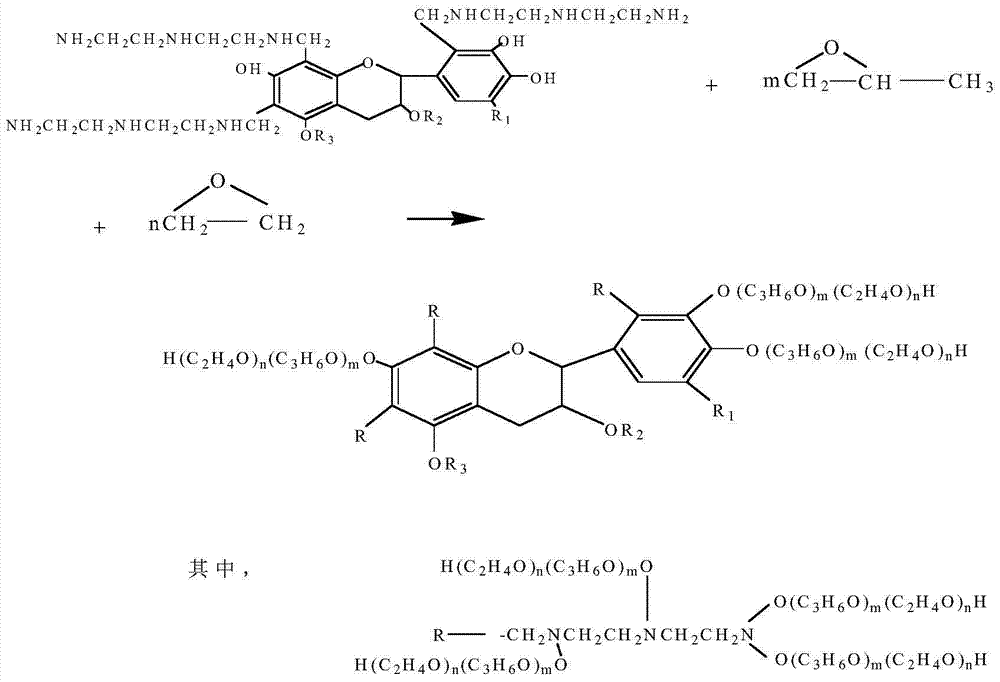

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Weigh 59.086g of tea polyphenols and 108.329g of diethylenetriamine in a 250mL four-neck bottle, stir for 30min at room temperature and under a nitrogen atmosphere, heat up to 70°C and continue stirring until the tea polyphenols are completely dissolved, and then After continuing to stir for 30 minutes, add 18.919 g of formaldehyde solution dropwise at a rate of 1 drop / s using a constant pressure dropping funnel. After the dropwise addition is completed, continue stirring at a constant temperature for 3 hours under a nitrogen atmosphere. Repeated several times to obtain a sufficient amount of product.

[0032] The obtained product should be distilled under reduced pressure at 150°C and 1.33kPa for 5 hours to remove excess formaldehyde, diethylenetriamine and reaction by-product water, and finally obtain a reddish-brown viscous liquid - tea polyphenol amine type Phenolic resin starter.

Embodiment 2

[0036] Weigh 59.086g of tea polyphenols and 108.329g of diethylenetriamine in a 250mL four-necked bottle, stir for 30 minutes at room temperature and nitrogen atmosphere, and continue stirring after raising the temperature to 70°C until the tea polyphenols are completely dissolved, and then continue stirring for 30 minutes 18.919g of formaldehyde solution was added dropwise at a rate of 1 drop / s with a constant pressure dropping funnel. After the dropwise addition was completed, the constant temperature stirring was continued for 3h under a nitrogen atmosphere. Repeated several times to obtain a sufficient amount of product.

[0037] The obtained product should be distilled under reduced pressure at 150°C and 1.33kPa for 5 hours to remove excess formaldehyde, triethylenetetramine and reaction by-product water, and finally obtain a reddish-brown viscous liquid - tea polyphenol amine type Phenolic resin starter.

[0038] 100 g of the initiator prepared in Example 2 and 1 g of p...

Embodiment 3

[0040] Weigh 59.086g of tea polyphenols and 108.329g of diethylenetriamine in a 250mL four-necked bottle, stir for 30 minutes at room temperature and nitrogen atmosphere, and continue stirring after raising the temperature to 70°C until the tea polyphenols are completely dissolved, and then continue stirring for 30 minutes 18.919g of formaldehyde solution was added dropwise at a rate of 1 drop / s with a constant pressure dropping funnel. After the dropwise addition was completed, the constant temperature stirring was continued for 3h under a nitrogen atmosphere. Repeated several times to obtain a sufficient amount of product.

[0041]The obtained product should be distilled under reduced pressure at 150°C and 1.33kPa for 5 hours to remove excess formaldehyde, tetraethylenepentamine and reaction by-product water, and finally obtain a reddish-brown viscous liquid - tea polyphenol amine type Phenolic resin starter.

[0042] 100 g of the initiator prepared in Example 2 and 3 g of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com