Preparation method for pH-responsive cross-linked multilayer membrane applied to oil-water separation

An oil-water separation and responsive technology, applied in the field of water treatment, can solve the problems of harsh polymerization conditions, time-consuming, complicated process, etc., achieve high anti-fouling performance, high separation efficiency, and reduce membrane fouling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

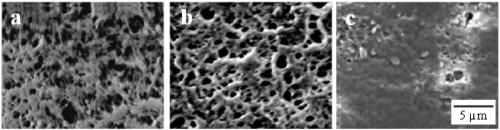

[0033] A method for preparing a pH-responsive cross-linked multilayer membrane for oil-water separation, comprising:

[0034] 1) Dissolve the weighed dopamine hydrochloride in tris-hydrochloride buffer solution (pH 7.5-9) to prepare a dopamine hydrochloride solution with a concentration of 2-50 g / L;

[0035] 2) Put the microfiltration membrane soaked with ethanol into the dopamine hydrochloride solution, shake and deposit for 12-72 h;

[0036] 3) Take out the microfiltration membrane, rinse it with ultrapure water first, then immerse it in ethanol, wash it with ultrapure water, and dry it for later use;

[0037] 4) Synthesis of polyacrylic acid-dopamine: prepare PBS buffer with a pH of 6 with dipotassium hydrogen phosphate and potassium dihydrogen phosphate, and add 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride in sequence Salt, N-hydroxysuccinimide and polyacrylic acid were dissolved in PBS buffer, filled with nitrogen and deoxygenated for 20-40 minutes, then ad...

Embodiment 1

[0042] A method for preparing a pH-responsive cross-linked multilayer membrane for oil-water separation, comprising:

[0043] 1) The weighed dopamine hydrochloride was dissolved in tris-hydrochloride buffer solution (pH 8.5) to prepare a dopamine hydrochloride solution with a concentration of 2 g / L;

[0044] 2) The polypropylene microfiltration membrane soaked with ethanol was placed in the dopamine hydrochloride solution and shaken for 12 h;

[0045] 3) Take out the polypropylene microfiltration membrane, rinse it with ultrapure water first, then immerse it in ethanol, wash it with ultrapure water, and dry it for later use;

[0046] 4) Synthesis of polyacrylic acid-dopamine: prepare PBS buffer with a pH of 6 with dipotassium hydrogen phosphate and potassium dihydrogen phosphate, and add 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride in sequence Salt, N-hydroxysuccinimide and polyacrylic acid were dissolved in PBS buffer, filled with nitrogen and deoxygenated for ...

Embodiment 2

[0052] A method for preparing a pH-responsive cross-linked multilayer membrane for oil-water separation, comprising:

[0053] 1) The weighed dopamine hydrochloride was dissolved in tris-hydrochloride buffer solution (pH 7.5) to prepare a dopamine hydrochloride solution with a concentration of 20 g / L;

[0054] 2) Put the polyvinylidene fluoride microfiltration membrane infiltrated with ethanol into the dopamine hydrochloride solution, shake and deposit for 24 h;

[0055] 3) Take out the polyvinylidene fluoride microfiltration membrane, first rinse it with ultrapure water, then immerse it in ethanol, wash it with ultrapure water, and dry it for later use;

[0056] 4) Synthesis of polyacrylic acid-dopamine: prepare PBS buffer with a pH of 6 with dipotassium hydrogen phosphate and potassium dihydrogen phosphate, and add 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride in sequence Salt, N-hydroxysuccinimide and polyacrylic acid were dissolved in PBS buffer, filled with n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com