A kind of aminated graphene oxide/high-density polyethylene nanocomposite film and preparation method thereof

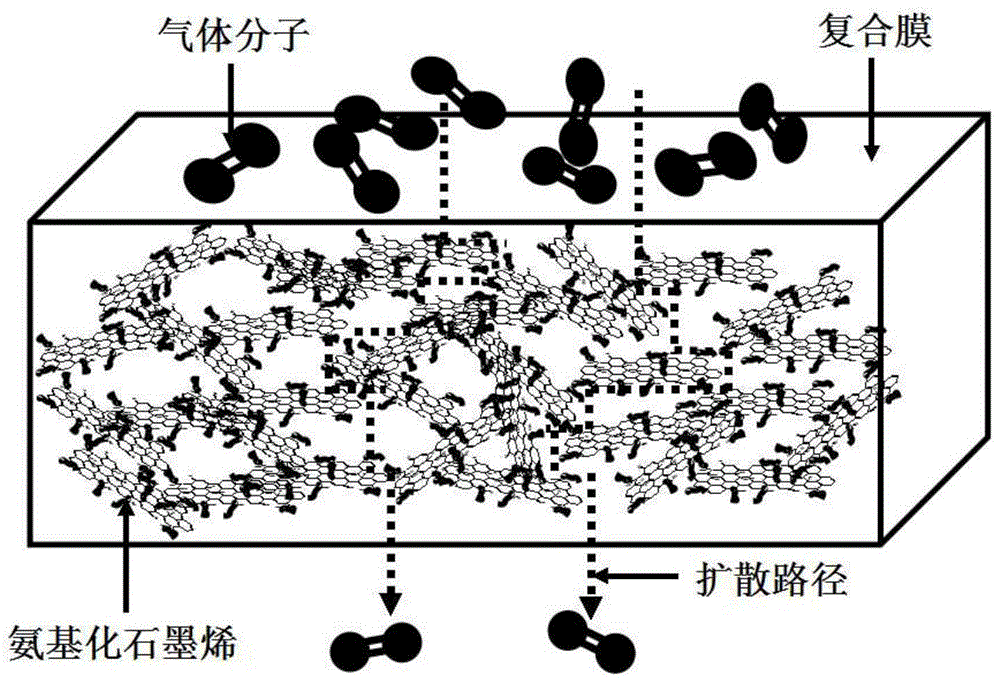

A high-density polyethylene and nanocomposite technology, applied in the direction of graphite, can solve the problems of non-polar polymer barrier properties, high barrier properties, and reduced gas permeation channels, so as to reduce the permeable area and improve barrier properties. , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of aminated graphene oxide / high-density polyethylene nanocomposite membrane and preparation method thereof, comprises the following steps:

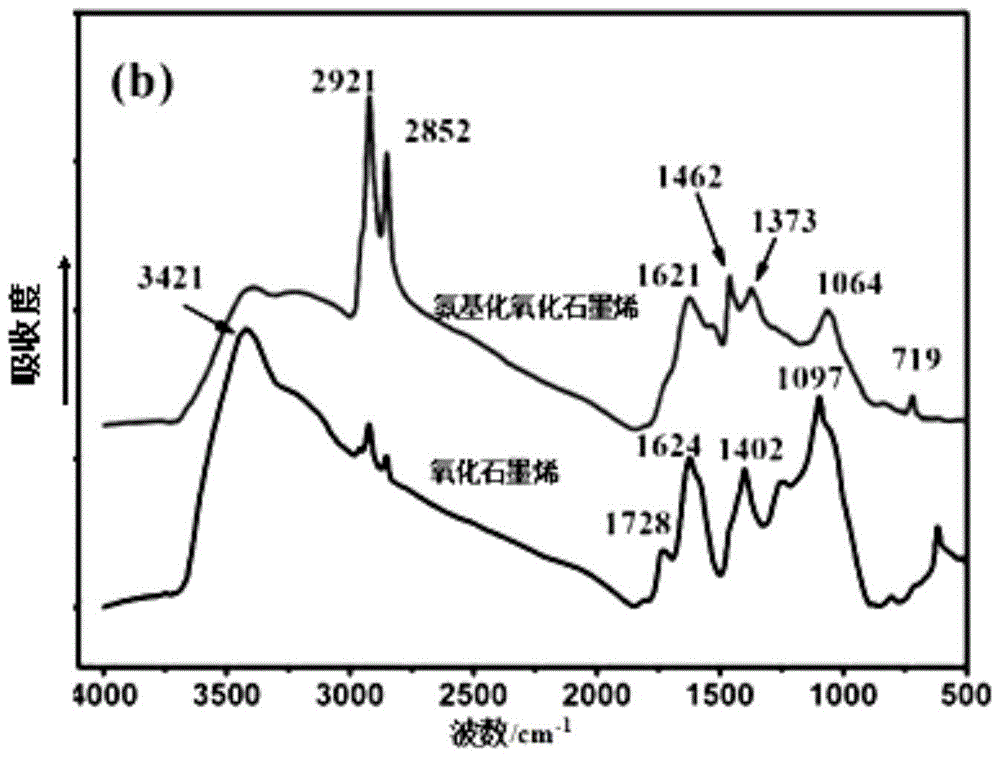

[0039] 1) Preparation of graphene oxide

[0040] First, graphene oxide was prepared by the improved Hummers method: 2 g of expandable graphite was weighed and added to 100 mL of concentrated H with a mass concentration of 98%. 2 SO 4 After stirring in an ice-water bath, gradually add 10g KMnO 4 , at 10°C, reacted for 2.5h. Then continue to react in a constant temperature water bath at 35°C for 1.25h, then add 400mL of deionized water and 5mL of 30% H 2 o 2 After stirring evenly, the mixture was filtered while it was hot, washed with 30 mL of 5% HCl solution, and then repeatedly washed with a large amount of deionized water until there was no SO in the filtrate. 4 2- (with BaCl 2 solution test), and then use ultrasonic action to disperse it in 200mL deionized water to obtain graphene oxide colloidal suspension.

[004...

Embodiment 2

[0049] A kind of aminated graphene oxide / high-density polyethylene nanocomposite membrane and preparation method thereof, comprises the following steps:

[0050] 1) Preparation of graphene oxide

[0051] First, graphene oxide was prepared by the improved Hummers method: 3g of expandable graphite was weighed and added to 110mL of concentrated H with a mass concentration of 98%. 2 SO 4 After stirring in an ice-water bath, gradually add 12g KMnO 4 , At 15°C, react for 2h. Then continue to react in a constant temperature water bath at 33°C for 1.5h, and then add 450mL of deionized water and 20mL of H2O with a mass concentration of 30% to the mixture system 2 o 2 After stirring evenly, the mixture was filtered while it was hot, washed with 35 mL of 5% HCl solution, and then repeatedly washed with a large amount of deionized water until there was no SO in the filtrate. 4 2- (with BaCl 2 solution test), and then use ultrasonic action to disperse it in 300mL deionized water to ...

Embodiment 3

[0058] A kind of aminated graphene oxide / high-density polyethylene nanocomposite membrane and preparation method thereof, comprises the following steps:

[0059] 1) Preparation of graphene oxide

[0060] First, graphene oxide was prepared by the improved Hummers method: 4g of expandable graphite was weighed and added to 120mL of concentrated H with a mass concentration of 98%. 2 SO 4 After stirring in an ice-water bath, gradually add 20g KMnO 4 , At 15°C, react for 2h. Subsequently, the reaction was continued for 1 h in a constant temperature water bath at 37°C, and 600 mL of deionized water and 25 mL of H2O with a mass concentration of 30% were successively added to the mixture system. 2 o 2 After stirring evenly, the mixture was filtered while it was hot, washed with 40 mL of 5% HCl solution, and then repeatedly washed with a large amount of deionized water until there was no SO in the filtrate. 4 2- (with BaCl2 solution test), and then use ultrasonic action to dispers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com