Method for leaching rare earth from weathering crust leaching type rare-earth ore heap

A weathering crust leaching type, rare earth ore technology, applied in the direction of improving process efficiency, can solve the problems of high impurity content of rare earth leaching mother liquor, low purity of rare earth products, and unfavorable vegetation restoration, so as to shorten the production cycle and realize The effect of high efficiency and accelerated growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

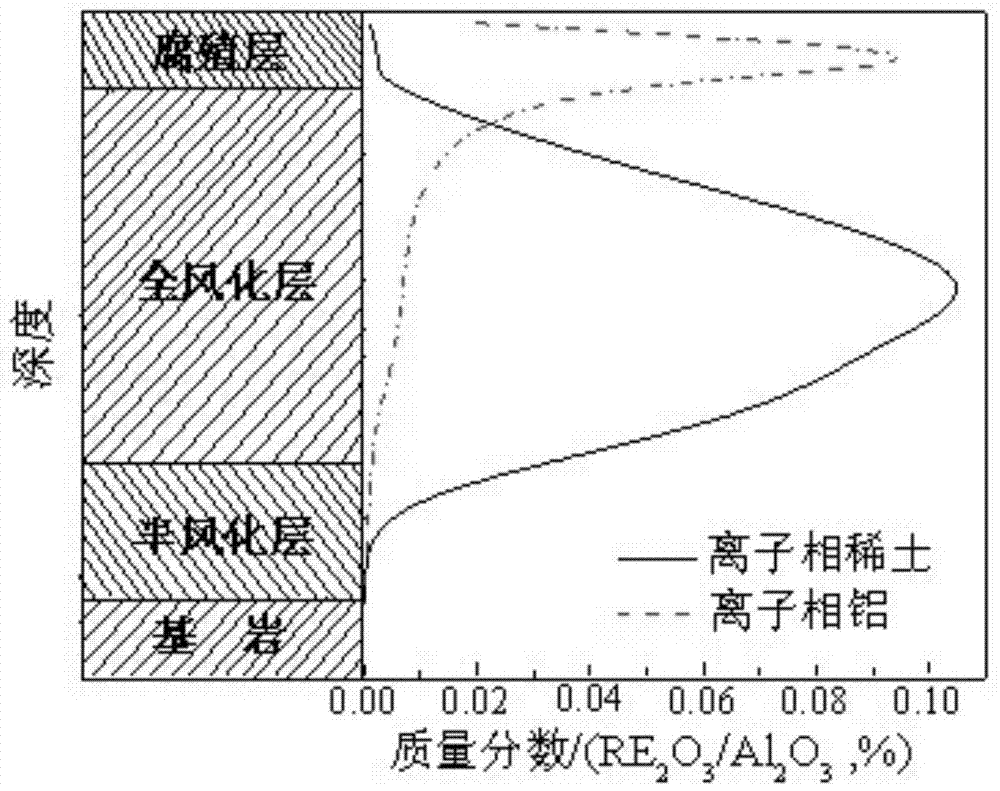

[0033] A weathering crust leaching type rare earth mine in Guangdong, the rare earth composition is medium yttrium rich in europium, and the average grade of rare earth is RE 2 o 30.078%, the content and thickness of the ionic rare earth and aluminum in the humic layer, fully weathered layer and semi-weathered layer are shown in Table 1.

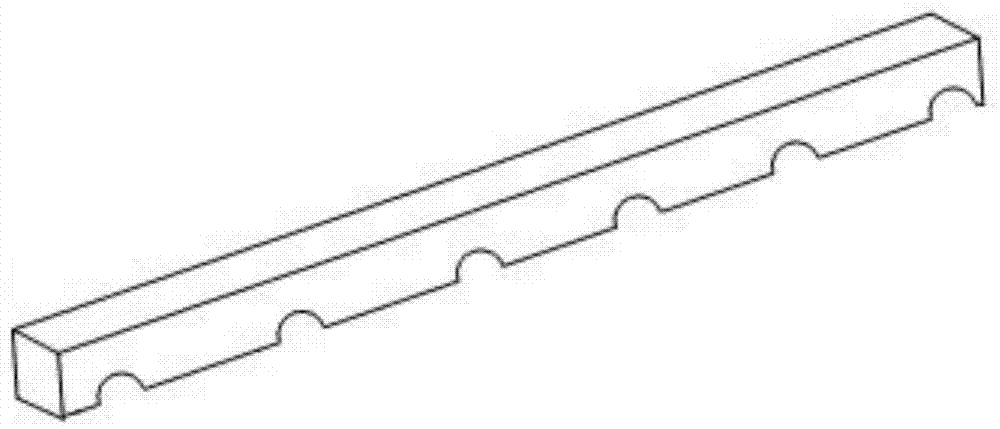

[0034] Rare earths were extracted by heap leaching. Firstly, the humus layer containing less rare earth and more aluminum on the mountain body is peeled off and placed separately for later use. Choose a valley that does not contain rare earths and is convenient for mining operations for leveling. The ground slope of the site is 1°. On the compacted site, a polyethylene plastic film coated with waterproof material is first laid as a leak-proof layer 1, and then a grid with a size of about 2×3m 2 The wooden frame 2 (top view as figure 2 shown), and every 30cm on the bottom of the wooden strip, open a semicircular hole with a diameter less...

Embodiment 2

[0039] A weathering crust leaching type rare earth mine in Guangdong, the rare earth composition is medium yttrium rich in europium, and the average grade of rare earth is RE 2 o 3 0.09%, the content and thickness of the exchangeable rare earth and aluminum in the humic layer, fully weathered layer and semi-weathered layer are shown in Table 2.

[0040] Rare earths were extracted by heap leaching. Firstly, the humus layer containing less rare earth and more aluminum on the mountain body is peeled off and placed separately for later use. Choose a valley that does not contain rare earth and is convenient for mining operations for leveling. The ground slope of the site is 3°. On the compacted site, a polyethylene plastic film coated with waterproof material is first laid as a leak-proof layer, and then a grid size of about 2 ×3m 2 A wooden frame is used, and a semicircular hole with a diameter less than half the thickness of the wooden bar is opened at the bottom of the wooden...

Embodiment 3

[0046] A weathering crust elution-type rare earth ore in Jiangxi, the rare earth composition is medium yttrium rich in europium, and the average grade of rare earth is RE 2 o 3 0.11%, the content and thickness of the exchangeable rare earth and aluminum in the humic layer, fully weathered layer and semi-weathered layer are shown in Table 3.

[0047] Rare earths were extracted by heap leaching. Firstly, the humus layer containing less rare earth and more aluminum on the mountain body is peeled off and placed separately for later use. Choose a valley that does not contain rare earths and is convenient for mining operations for leveling. The ground slope of the site is 5°. On the compacted site, a polyethylene plastic film coated with waterproof material is first laid as a leak-proof layer, and then a grid with a size of about 2 ×3m 2 A wooden frame is used, and a semicircular hole with a diameter less than half the thickness of the wooden bar is opened at the bottom of the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com