Microparticle feed for grouper fries and preparation method for microparticle feed

A technology of micro-granule feed and fry, applied in animal feed, animal feed, application and other directions, can solve the problems of low survival rate of fry cultivation, unstable quality and quantity of biological bait, and high cultivation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

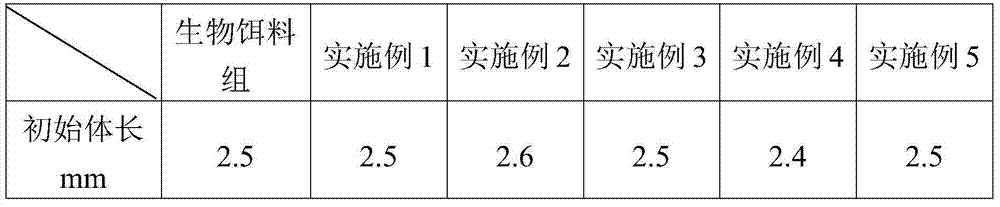

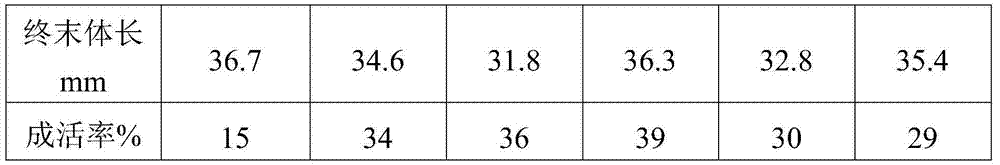

Examples

Embodiment 1

[0057] A kind of micro-granule feed for grouper fry, in 1000 kg, its formula contains the following materials: 360 kg of Antarctic krill powder, 200 kg of poultry egg protein powder, 125 kg of white fish meal, 40 kg of yellow worm powder, 100 kg of α-starch kg, 50 kg of concentrated soybean protein, 50 kg of gluten, 25 kg of fish oil, 20 kg of phospholipid oil, 15 kg of calcium dihydrogen phosphate, 5.0 kg of fish trace elements, 2.5 kg of choline, 2.0 kg of betaine, 1.2 kg of bentonite, Fish multivitamin 1.0 kg, antifungal agent 1.0 kg, vitamin C 1.0 kg, carnitine 0.5 kg, antioxidant 0.5 kg and inositol 0.3 kg.

[0058] The preparation method of this grouper fry microparticle feed comprises the steps:

[0059] (1) According to the formula, fish trace elements, choline, betaine, bentonite, fish multidimensional, antifungal agent, vitamins, carnitine, antioxidant, inositol and α-starch are mixed uniformly through a mixer to make a small additive; Mix Antarctic krill powder, po...

Embodiment 2

[0064] A kind of micro-granule feed for grouper fry, in 1000 kg, its formula contains the following materials: 380 kg of Antarctic krill powder, 190 kg of poultry egg protein powder, 120 kg of white fish meal, 35 kg of yellow worm powder, 100 kg of α-starch kg, 50 kg of concentrated soybean protein, 50 kg of gluten, 25 kg of fish oil, 20 kg of phospholipid oil, 15 kg of calcium dihydrogen phosphate, 5.0 kg of fish trace elements, 2.5 kg of choline, 2.0 kg of betaine, 1.2 kg of bentonite, Fish multivitamin 1.0 kg, antifungal agent 1.0 kg, vitamin C 1.0 kg, carnitine 0.5 kg, antioxidant 0.5 kg and inositol 0.3 kg.

[0065] The preparation method is the same as in Example 1.

Embodiment 3

[0067] A kind of grouper fry microparticle feed, in 1000 kg, its formula contains the following materials: 400 kg of Antarctic krill powder, 180 kg of poultry egg protein powder, 115 kg of white fish meal, 30 kg of yellow worm powder, 100 kg of α-starch kg, 50 kg of concentrated soybean protein, 50 kg of gluten, 25 kg of fish oil, 20 kg of phospholipid oil, 15 kg of calcium dihydrogen phosphate, 5.0 kg of fish trace elements, 2.5 kg of choline, 2.0 kg of betaine, 1.2 kg of bentonite, Fish multivitamin 1.0 kg, antifungal agent 1.0 kg, vitamin C 1.0 kg, carnitine 0.5 kg, antioxidant 0.5 kg and inositol 0.3 kg.

[0068] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com