Preparation method of nano-barium sulfate

A technology of nano barium sulfate and barium sulfate, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., to achieve the effect of small particle size, high dispersion, and less non-barium sulfate impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

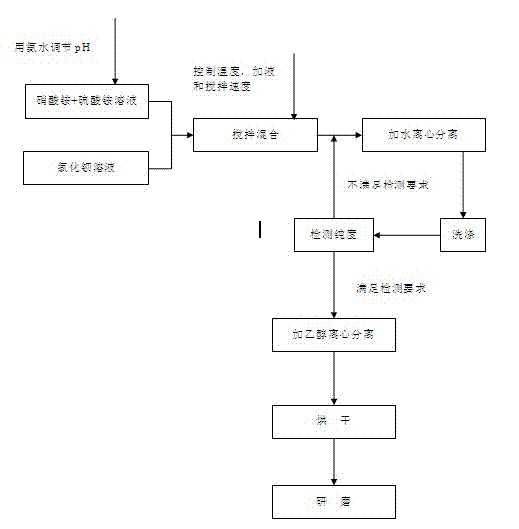

Image

Examples

Embodiment 1

[0023] A, adopt the accompanying drawing of technological process of the present invention, prepare 2mol / L ammonium sulfate and 4mol / L ammonium nitrate of same volume mix, adjust the pH of mixed solution by dripping ammoniacal liquor to be 10;

[0024] b. Heat the mixed solution to 60°C, mix well under stirring at 200rpm, add 0.8mol / L barium chloride solution dropwise to the mixed solution until the molar number of added barium chloride is the same as that of ammonium sulfate, and the dropwise reaction time For 20min, the solution was turned into a white barium sulfate emulsion;

[0025] c. Use a centrifuge to separate the barium sulfate emulsion generated. The speed of the centrifuge is 1000rpm, and the separation time is 2min. The upper layer solution is discarded and water is added to the original volume, and the bottom layer is mixed with water. Centrifuge the barium sulfate emulsion, take a small amount of the upper layer solution and mix it with silver nitrate (1%), cont...

Embodiment 2

[0028] A, adopt accompanying drawing of technological process of the present invention, prepare 3mol / L ammonium sulfate and 5mol / L ammonium nitrate of same volume mix, adjust the pH of mixed solution by dripping ammoniacal liquor to be 8;

[0029] b. Heat the mixed solution to 80°C, mix evenly under stirring at 1000rpm, add 0.1mol / L barium chloride solution dropwise to the mixed solution until the molar number of added barium chloride is the same as that of ammonium sulfate, and the dropwise reaction time For 40min, the solution was turned into a white barium sulfate emulsion;

[0030] c. Use a centrifuge to separate the barium sulfate emulsion generated. The centrifuge speed is 5000rpm, and the separation time is 4min. The upper layer solution is discarded and water is added to the original volume, and the bottom layer is mixed with water. Centrifuge the barium sulfate emulsion, take a small amount of the upper layer solution and mix it with silver nitrate (1%), continue to a...

Embodiment 3

[0033] a, adopt the accompanying drawing of technological process of the present invention, prepare 2mol / L ammonium sulfate and 4mol / L ammonium nitrate of same volume mix, adjust the pH of mixed solution by dripping ammoniacal liquor to be 8;

[0034] b. Heat the mixed solution to 70°C, mix well under stirring at 600rpm, add 0.4mol / L barium chloride solution dropwise to the mixed solution until the molar number of added barium chloride is the same as that of ammonium sulfate, and the dropwise reaction time For 30min, the solution was turned into a white barium sulfate emulsion;

[0035] c. Use a centrifuge to separate the barium sulfate emulsion generated. The centrifuge speed is 2000rpm, and the separation time is 2min. The upper solution is discarded and water is added to the original volume. The bottom layer is mixed with water. Centrifuge the barium sulfate emulsion, take a small amount of the upper layer solution and mix it with silver nitrate (1%), continue to add water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com