Less-slag and energy-saving method for smelting secondary lead through side-blown molten pool smelting furnace

A molten pool smelting furnace and recycled lead smelting technology, applied in the direction of improving process efficiency, can solve problems such as unsuitable lead paste, flue ash smelting, etc., to shorten the smelting cycle, improve economic benefits, and reduce the amount of smelting slag. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

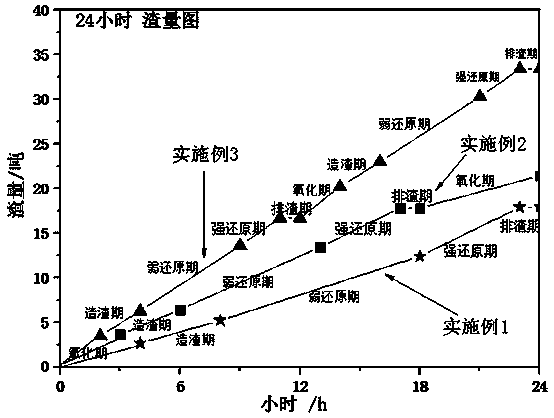

Embodiment 1

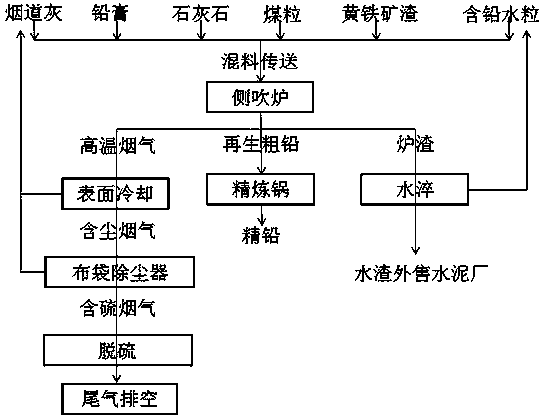

[0023] combined with figure 1 The production process shown is a secondary lead smelting method with less slag and energy saving in side-blown molten pool melting furnace. This method divides the smelting process into slag oxidation period, slagging period, weak reduction period, strong reduction period, and slag discharge period There are five phases in total, and the control of each phase needs to regulate the gas, materials, atmosphere and other key points of the furnace body to achieve the purpose of harmless slag and maximum lead extraction. The alkalinity of slag is 1~1.25 、Density≤3.5g / cm 3 , slag containing lead ≤ 2%, and finally enter the slag discharge period.

[0024] 1. Slag oxidation period

[0025] During smelting, natural gas and oxygen-enriched air are blown into the side-blown furnace from the side, and the pressure of the natural gas in the spray gun is 0.2Mpa, and the pressure of oxygen-enriched air is 0.3Mpa. Control the flow of natural gas at 400~420m du...

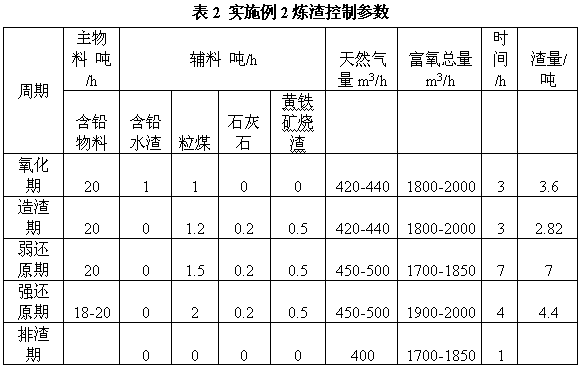

Embodiment 2

[0037] combined with figure 1 The production process shown is a secondary lead smelting method with less slag and energy saving in side-blown molten pool melting furnace. This method divides the smelting process into slag oxidation period, slagging period, weak reduction period, strong reduction period, and slag discharge period There are five phases in total, and the control of each phase needs to regulate the gas, materials, atmosphere and other key points of the furnace body to achieve the purpose of harmless slag and maximum lead extraction. The alkalinity of slag is 1~1.25 、Density≤3.5g / cm 3 , slag containing lead ≤ 2%, and finally enter the slag discharge period.

[0038] 1. Slag oxidation period

[0039] During smelting, natural gas and oxygen-enriched air are blown into the side-blowing furnace from the side, the pressure of natural gas in the spray gun is 0.2Mpa, and the pressure of oxygen-enriched air is 0.3Mpa. Control the flow rate of natural gas at 420~440m dur...

Embodiment 3

[0051] combined with figure 1 The production process shown is a secondary lead smelting method with less slag and energy saving in side-blown molten pool melting furnace. This method divides the smelting process into slag oxidation period, slagging period, weak reduction period, strong reduction period, and slag discharge period There are five phases in total, and the control of each phase needs to regulate the gas, materials, atmosphere and other key points of the furnace body to achieve the purpose of harmless slag and maximum lead extraction. The alkalinity of slag is 1~1.25 、Density≤3.5g / cm 3 , slag containing lead ≤ 2%, and finally enter the slag discharge period.

[0052] 1. Slag oxidation period

[0053] During smelting, natural gas and oxygen-enriched air are blown into the side-blowing furnace from the side, the pressure of natural gas in the spray gun is 0.2Mpa, and the pressure of oxygen-enriched air is 0.3Mpa. Control the flow rate of natural gas at 420~440m dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com