Method for separating petunidin in lycium ruthenicum murray through high-speed counter-current chromatography

A technology of high-speed countercurrent chromatography and black fruit wolfberry, which is applied in the direction of organic chemistry, etc., to achieve the effect of simple process, convenient operation and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Preparation of crude extract

[0024] Add 100mL of methanol (2% formic acid) to 100g of dried fruit of Lycium barbarum to extract for 24h, and repeat 3 times. After 3 times of extracts were combined, filter paper was used to remove insoluble matter, protein, and polysaccharides. After the filtrate was collected, the methanol was concentrated by a rotary evaporator, and the extract was redissolved in distilled water (2% formic acid) and applied to D-101 macroporous resin (50mm×800mm). The macroporous resin was pretreated with methanol and water. After loading the sample, flush the column with 3 times the column volume of distilled water to remove sugars, amino acids and other impurities. Then wash the column with methanol, collect the effluent, concentrate and dry under reduced pressure to obtain the crude extract.

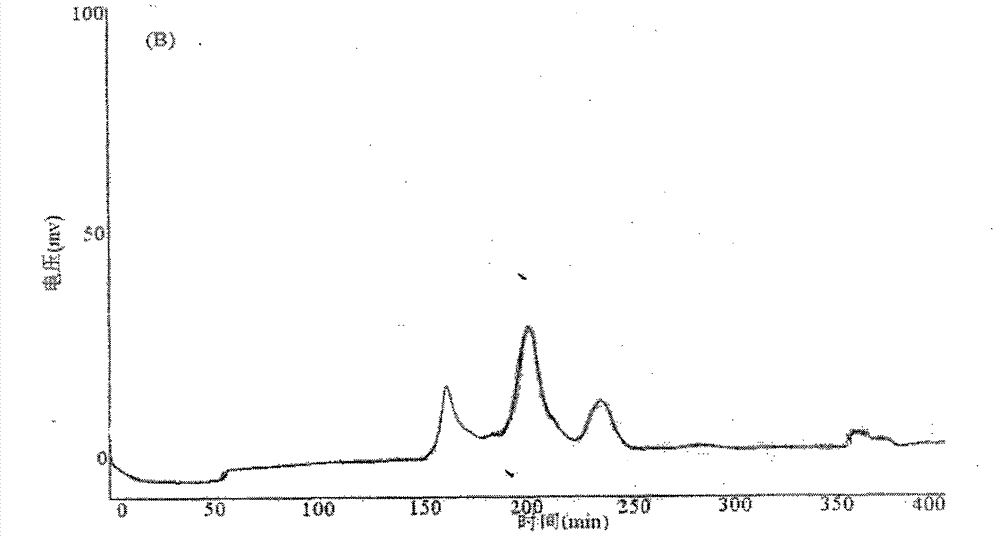

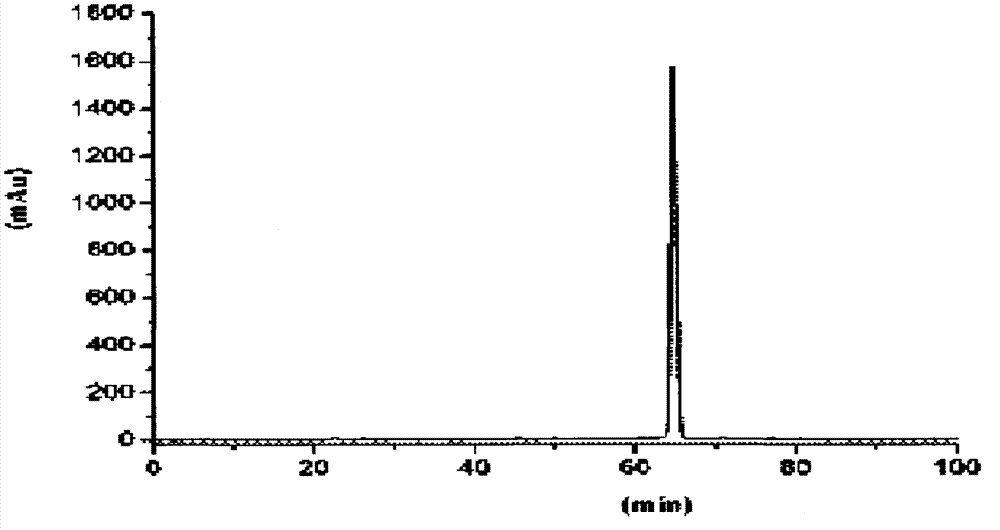

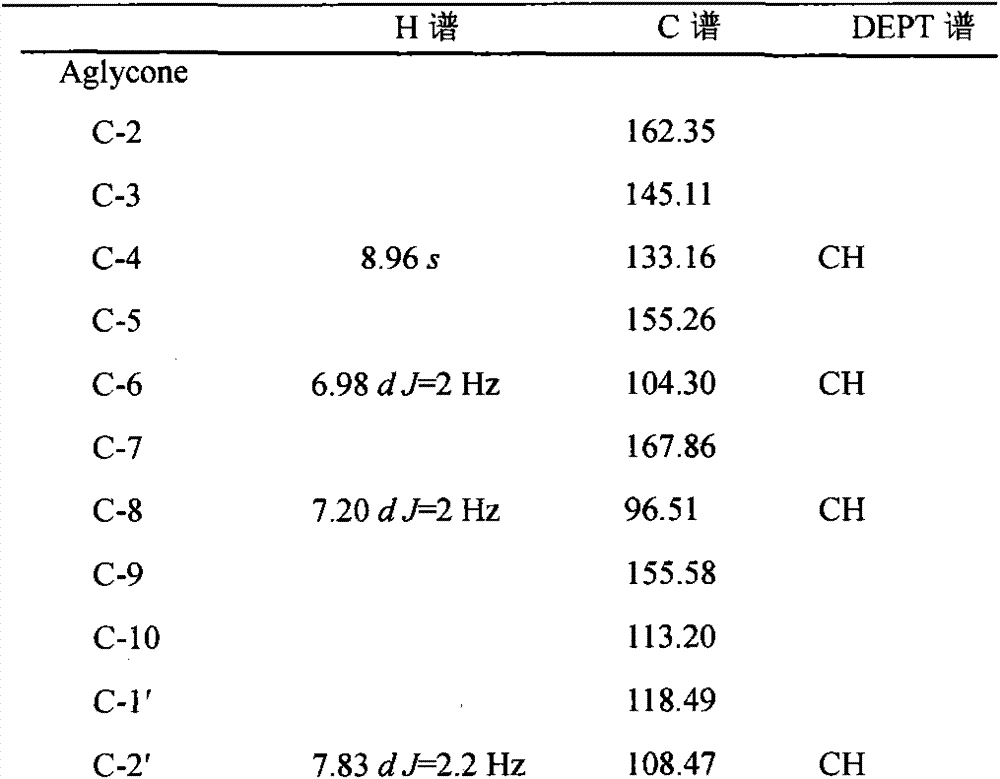

[0025] 2. Preparation of Lycium barbarum anthocyanins by high-speed countercurrent separation

Embodiment 2

[0036] 1. Preparation of crude extract

[0037] Add 100mL of methanol (2% formic acid) to 100g of dried fruit of Lycium barbarum to extract for 24h, and repeat 3 times. After 3 times of extracts were combined, filter paper was used to remove insoluble matter, protein, and polysaccharides. After the filtrate was collected, the rotary evaporator was concentrated to remove methanol, and the extract was reconstituted with distilled water (2.% formic acid) and applied to D-101 macroporous resin (50mm×800mm). The macroporous resin was pretreated with methanol and water. After loading the sample, flush the column with 3 times the column volume of distilled water to remove sugars, amino acids and other impurities. Then wash the column with methanol, collect the effluent, concentrate and dry under reduced pressure to obtain the crude extract.

[0038] 2. High-speed countercurrent separation

[0039] Prepare a two-phase solvent system of methyl tert-butyl ether: n-butanol: acetonitr...

Embodiment 3

[0042] 1. Preparation of crude extract

[0043] Add 100mL of methanol (2% formic acid) to 100g of dried fruit of Lycium barbarum to extract for 24h, and repeat 3 times. The extraction process was carried out at room temperature and protected from light. After 3 times of extracts were combined, filter paper was used to remove insoluble matter, protein, and polysaccharides. After the filtrate was collected, the methanol was concentrated by a rotary evaporator, and the extract was redissolved in distilled water (2% formic acid) and applied to D-101 macroporous resin (50mm×800mm). The macroporous resin was pretreated with methanol and water. After loading the sample, flush the column with 3 times the column volume of distilled water to remove sugars, amino acids and other impurities. Then wash the column with methanol, collect the effluent, concentrate and dry under reduced pressure to obtain the crude extract.

[0044] 2. High-speed countercurrent separation

[0045] Prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com