Cultivation method for repeated oyster mushroom fruiting

A cultivation method and technology of oyster mushrooms, applied in the fields of mushroom cultivation, cultivation, plant cultivation, etc., can solve the problems such as mushroom bags and re-emergence of oyster mushrooms that have not been seen yet, achieve good market application prospects, and save manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

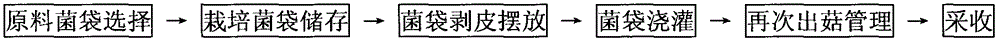

Method used

Image

Examples

Embodiment 1

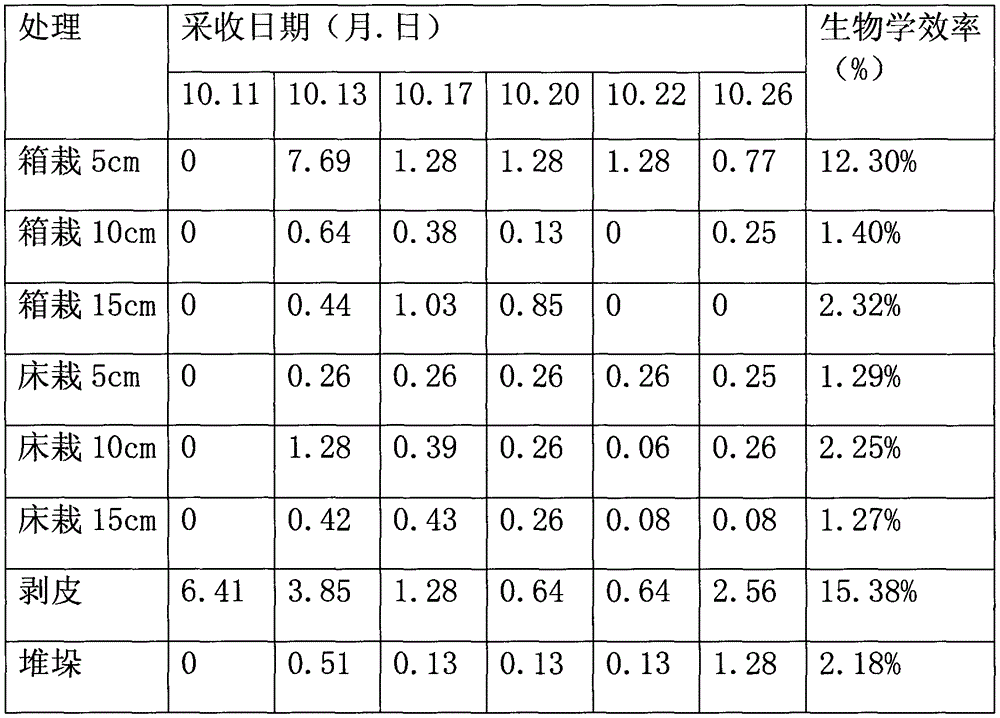

[0023] Embodiment 1: Cultivate flat mushrooms in summer, fruiting in autumn, method for fruiting again in winter and spring

[0024] The mass percent of the medium formula composition of flat mushroom sporocarp growth and development is:

[0025] Formula 1: 77% mulberry twigs, 20% rice bran or wheat bran, 1% white sugar, 1% superphosphate and 1% gypsum powder.

[0026] Formula 2: 87% cottonseed hulls, 10% rice bran, 1% superphosphate, 1% gypsum powder, 1% lime powder.

[0027] Formula three: 78% bagasse, 20% rice bran or wheat bran, 1% superphosphate, 1% gypsum powder.

[0028] Utilize the formula above to select a suitable variety of Pleurotus ostreatus, and in the middle and late August, the ingredients are bagged and inoculated, for example, according to the following method to realize the fruiting cultivation and re-fruiting of Pleurotus ostreatus.

[0029] (1) Ingredients, mix the raw materials according to the recipe, add water about 1.3 times the mass of the raw mater...

Embodiment 2

[0041] Embodiment 2: the cultivation method of oyster mushroom in winter, fruiting in spring, and fruiting again in autumn.

[0042] (1) Preparation of raw materials: After the harvest of agricultural and sideline products in autumn, prepare raw materials for planting oyster mushrooms, using wood chips, cottonseed hulls, corncobs, soybean straw, peanut shells, cotton stalks, mulberry powder, etc. as the main raw materials.

[0043] (2) Raw material processing: According to the raw materials and seasons in the cultivation area, raw material cultivation, fermented material cultivation and clinker cultivation are selected.

[0044] (3) Cultivation bag production: use bag cultivation technology, clinker cultivation bagged and then sterilized and inoculated, raw material and fermented material cultivated and bagged and inoculated at the same time, and cultivated after binding.

[0045] (4) Bacteria bag cultivation: After the cultivation bag is inoculated, it has entered the season ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com