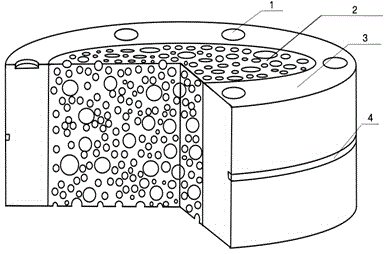

Intervertebral disc imitating spine fuser and preparing method thereof

A spinal fusion and intervertebral disc imitation technology, applied in the direction of fixator, internal fixator, internal bone synthesis, etc., can solve the problems such as difficulty in forming hydroxyapatite into a scaffold, difficulty in forming a cellulose scaffold, and difficulty in controlling the degradation rate, etc. Good clinical use effect, convenient operation, and the effect of reducing the pain of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0021] 1) Weigh 9 grams of chitosan powder, add it to 300 milliliters of 2% acetic acid aqueous solution, and stir mechanically for 2 hours to obtain a uniform and transparent chitosan solution. Pour it into a ring-shaped mold, immerse in a 3% sodium hydroxide aqueous solution for 2 hours to gel, wash and dry to obtain a ring-shaped cylindrical stent;

[0022] 2) Weigh 1g of chitosan and dissolve it in 100g of 2% acetic acid aqueous solution, prepare a 1% chitosan acetic acid solution, fill it into the inner cylinder of the annular cylindrical stent, and gel it with 3% sodium hydroxide melted, washed with water, and freeze-dried at -20°C to obtain a chitosan porous structure core layer with a porosity of 95% and a pore diameter of 500 μm;

[0023] 3) Dissolve interferon and bone morphogenetic protein in PBS solution, then add nano-hydroxyapatite to obtain a mixed dispersion, so that the concentration of interferon in the mixed dispersion is 10ng / mL, and the concentration of bo...

example 2

[0026] 1) Weigh 15 grams of chitosan powder, add it to 300 ml of 3% acetic acid aqueous solution, and stir mechanically for 2 hours to obtain a uniform and transparent chitosan solution. Pour it into a ring-shaped mold, immerse in a 3% sodium hydroxide aqueous solution for 2 hours to gel, wash and dry to obtain a ring-shaped cylindrical stent;

[0027] 2) Weigh 3g of chitosan and dissolve it in 100g of 2% acetic acid aqueous solution to prepare a 3% chitosan acetic acid solution, fill it into the inner cylinder of the annular cylindrical support, and then solidify it with 4% sodium hydroxide. Gelling, washing with water, and freeze-drying at -40°C to obtain a chitosan porous structure core layer with a porosity of 90% and a pore diameter of 350 μm;

[0028] 3) Dissolve interferon and bone morphogenetic protein in PBS solution, then add nano-hydroxyapatite to obtain a mixed dispersion, so that the concentration of interferon in the mixed dispersion is 100ng / mL, and the concentr...

example 3

[0031] 1) Weigh 20 grams of chitosan powder, add it to 300 milliliters of 4% acetic acid aqueous solution, and stir mechanically for 2 hours to obtain a uniform and transparent chitosan solution. Pour it into a ring-shaped mold, immerse in a 5% sodium hydroxide aqueous solution for 2 hours to gel, wash and dry to obtain a ring-shaped cylindrical stent;

[0032] 2) Weigh 5g of chitosan and dissolve it in 100g of 3% acetic acid aqueous solution, prepare a 5% chitosan acetic acid solution, fill it into the inner cylinder of the annular cylindrical stent, and gel it with 5% sodium hydroxide melted, washed with water, frozen at -40°C, and dried to obtain a chitosan porous structure core layer with a porosity of 85% and a pore diameter of 270 μm;

[0033] 3) Dissolve interferon and bone morphogenetic protein in PBS solution, then add nano-hydroxyapatite to obtain a mixed dispersion, so that the concentration of interferon in the mixed dispersion is 300ng / mL, and the concentration of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com