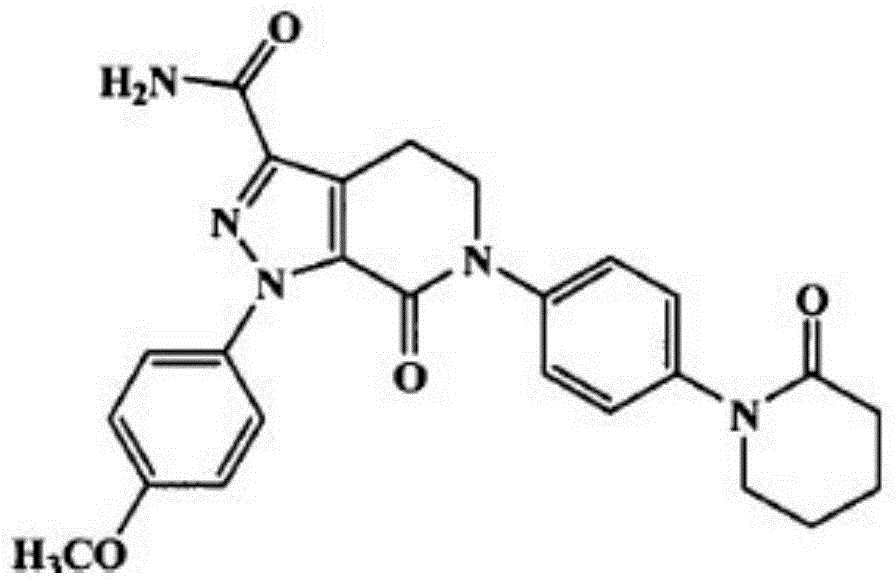

Apixaban tablet and preparation method thereof

A technology for apixaban tablets and excipients, applied in the field of apixaban tablets and its preparation, can solve the problems of low in vitro dissolution rate, low bioavailability, slow dissolution rate, etc., and achieve simple preparation process, The effect of high bioavailability and low packaging cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Components of Apixaban Tablets

[0029] components

Dose 1 (mg)

Dose 2 (mg)

Dose 3 (mg)

10

20

30

38

76

114

70

140

210

2

4

6

2

4

6

0.2

0.4

0.6

[0030] Preparation Process:

[0031] (1) Weigh the raw and auxiliary materials of the above prescription amount, except for magnesium stearate, mix all the raw and auxiliary materials and carry out wet granulation. The soft material obtained is granulated with a 20-mesh sieve, and the obtained granules are dried and granulated. Granules, and finally collect dry particles between 20 mesh and 80 mesh.

[0032] (2) After mixing the prepared granules with magnesium stearate for 30 minutes, press into tablets, and the hardness of the tablets is 50-60N.

Embodiment 2

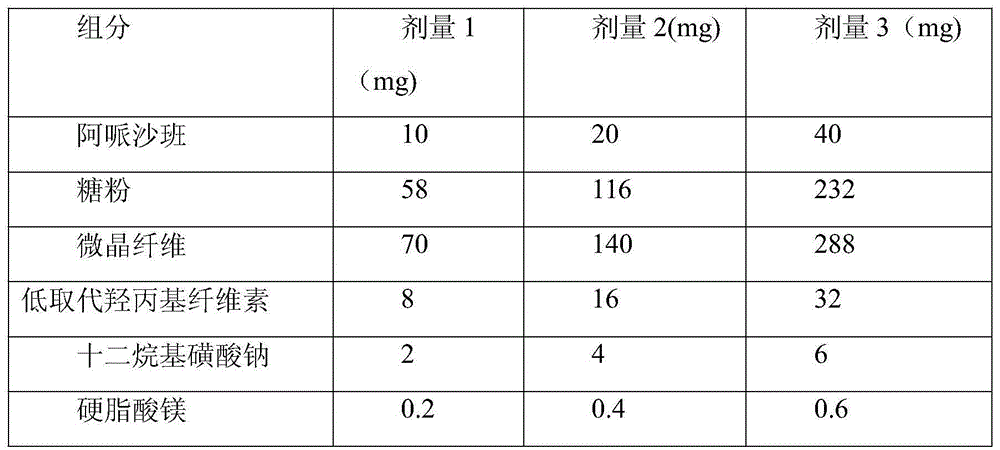

[0034] Apixaban Tablet Ingredients

[0035] components

Dose 1 (mg)

Dose 2 (mg)

Dose 3 (mg)

Apixaban

10

20

40

powdered sugar

60

120

250

22

40

88

Crospovidone

3

6

16

2

4

6

Magnesium stearate

0.2

0.4

0.6

[0036] Preparation Process:

[0037] (1) Weigh the raw and auxiliary materials of the above prescription amount, except for magnesium stearate, mix all the raw and auxiliary materials and carry out wet granulation. The soft material obtained is granulated with a 20-mesh sieve, and the obtained granules are dried and granulated. Granules, and finally collect dry particles between 20 mesh and 80 mesh.

[0038] (2) After mixing the prepared granules with magnesium stearate for 30 minutes, press into tablets, and the hardness of the tablets is 50-60N.

Embodiment 3

[0040] Components of Apixaban Tablets

[0041]

[0042] Preparation Process:

[0043] (1) Weigh the raw and auxiliary materials of the above prescription amount, except for magnesium stearate, mix all the raw and auxiliary materials and carry out wet granulation. The soft material obtained is granulated with a 20-mesh sieve, and the obtained granules are dried and granulated. Granules, and finally collect dry particles between 20 mesh and 80 mesh.

[0044] (2) After mixing the prepared granules with magnesium stearate for 30 minutes, press into tablets, and the hardness of the tablets is 50-60N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com