Simple preparation of expanded mesoporous silicon dioxide and dissolution promoting application of expanded mesoporous silicon dioxide

A mesoporous silica and silicon dioxide technology, applied in the direction of silica and silicon oxide, can solve the problems of low bioavailability of carvedilol, strong lipophilicity of carvedilol, complex synthesis process, etc. Achieve the effect of short cycle, large specific surface area and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

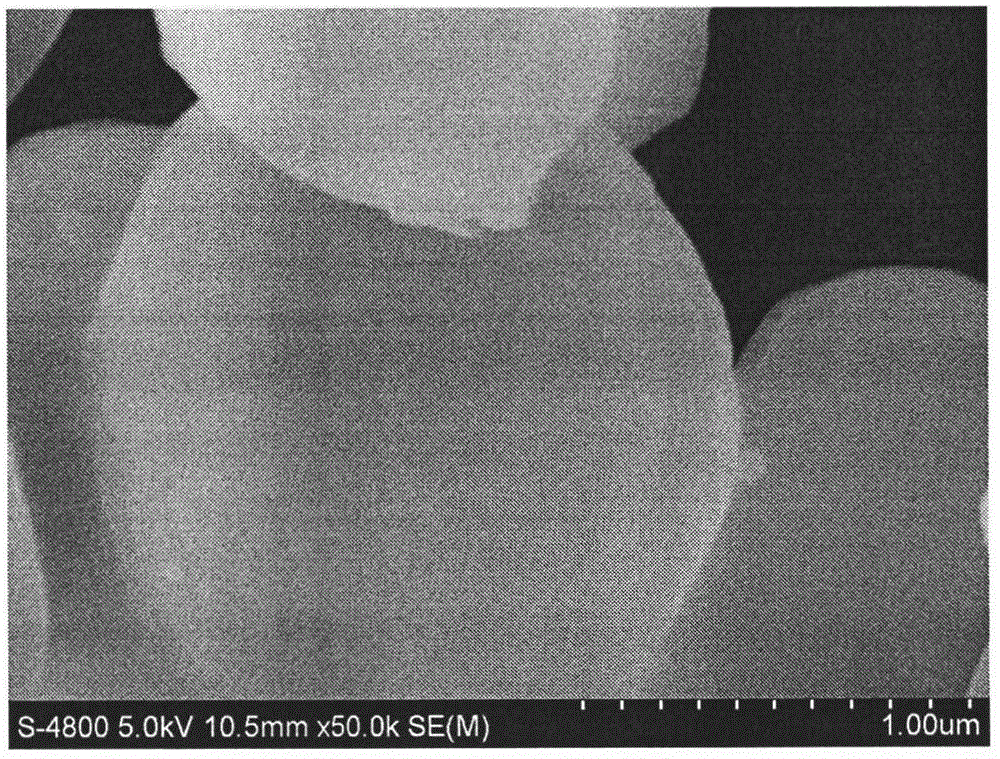

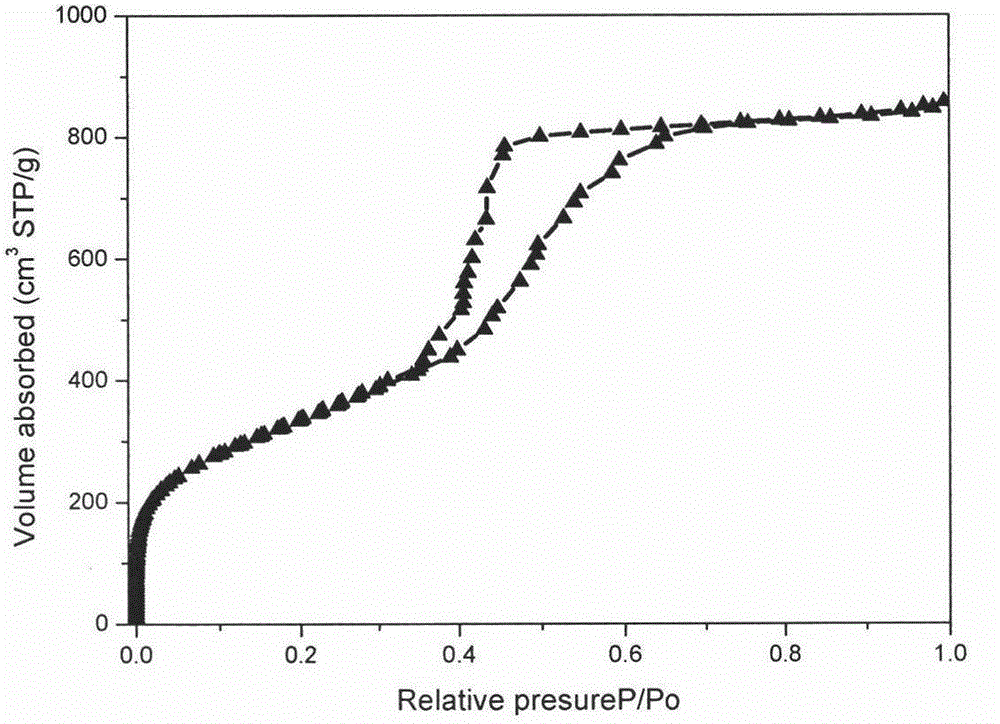

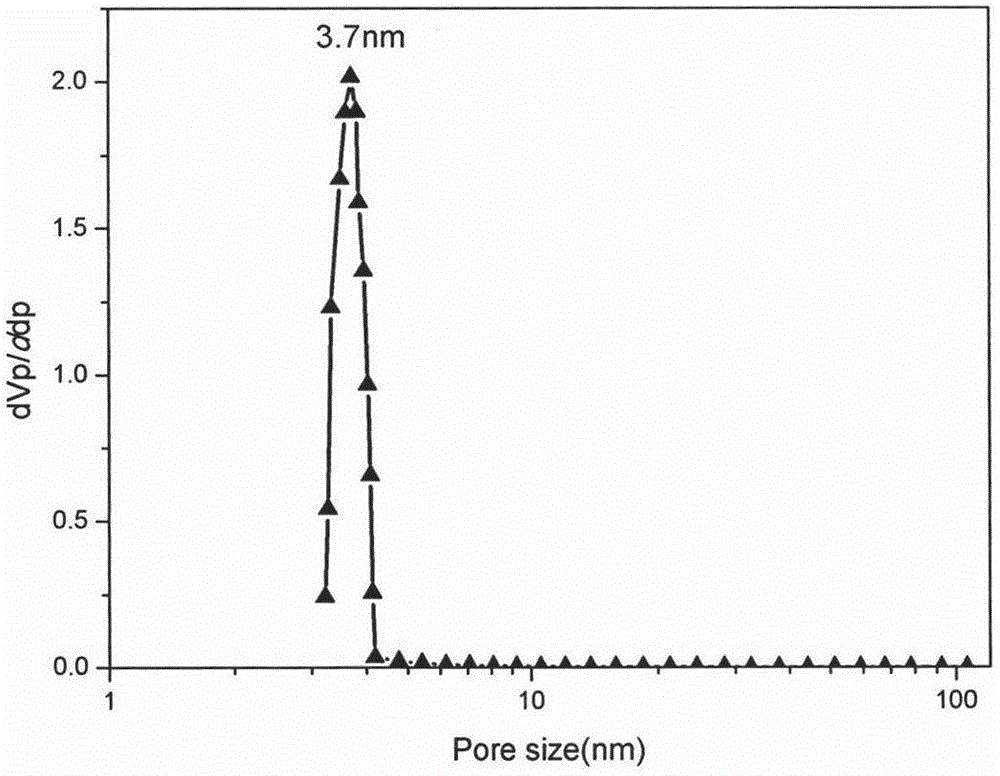

[0028] Example 1: Preparation of expanded mesoporous silica particles

[0029] (1) 0.2g of dodecyltrimethylammonium bromide and 0.35g of cetyltrimethylammonium bromide are dissolved in 200ml deionized water to form a transparent solution; 0.2g of octane is dissolved in 6ml Octane ethanol solution in ethanol.

[0030] (2) The above two solutions were mixed and ultrasonicated for 20 minutes, and then 0.3 g of sodium hydroxide was added; then 5 g of tetraethyl orthosilicate was slowly added dropwise under the condition of stirring at 80°C.

[0031] (3) React for 120 minutes under stirring at 80°C to obtain white silica emulsion; then stop stirring, filter and wash to obtain silica containing surfactant.

[0032] (4) Place the above silicon dioxide in a hydrochloric acid / ethanol solution to reflux for 3 hours, filter, wash and dry to obtain a pore-expanding silicon dioxide product with a large surface area.

Embodiment 2

[0033] Example 2: Preparation of expanded mesoporous silica particles

[0034] (1) 0.5 g of cetyltrimethylammonium bromide was dissolved in 150 ml of deionized water to form a transparent solution; 0.3 g of octane was dissolved in 8 ml of ethanol to obtain an octane ethanol solution.

[0035] (2) The above two solutions were mixed and ultrasonicated for 20 minutes, and then 0.3 g of sodium hydroxide was added; then 5 g of tetraethyl orthosilicate was slowly added dropwise under the condition of stirring at 80°C.

[0036] (3) React for 120 minutes under stirring at 80° C. to obtain white silica emulsion; then stop stirring, filter and wash to obtain silica containing surfactant.

[0037] (4) Place the above silicon dioxide in a hydrochloric acid / ethanol solution to reflux for 3 hours, filter, wash and dry to obtain a pore-expanding silicon dioxide product with a large surface area.

Embodiment 3

[0038] Example 3: Preparation of expanded mesoporous silica particles

[0039] (1) 0.6 g of cetyltrimethylammonium bromide was dissolved in 300 ml of deionized water to form a transparent solution; 0.5 g of decane was dissolved in 10 ml of ethanol to prepare a decane ethanol solution.

[0040] (2) The above two solutions were mixed and ultrasonicated for 20 minutes, and then 0.48 g of sodium hydroxide was added; then 5.6 g of tetraethyl orthosilicate was slowly added dropwise under the condition of stirring at 80°C.

[0041] (3) React for 120 minutes under stirring at 80° C. to obtain white silica emulsion; then stop stirring, filter and wash to obtain silica containing surfactant.

[0042] (4) Place the above silicon dioxide in a hydrochloric acid / ethanol solution to reflux for 3 hours, filter, wash and dry to obtain a pore-expanding silicon dioxide product with a large surface area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com