Preparation of hydrophilic acrylic adsorption resin and application of acrylic adsorption resin in phenolic wastewater treatment

An acrylate, adsorption resin technology, applied in adsorption water/sewage treatment, other chemical processes, chemical instruments and methods, etc., can solve problems such as inability to contact phenol, damage to human cells, and unsatisfactory adsorption effect, and achieve improved treatment. ability, enhance the effect of effective contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

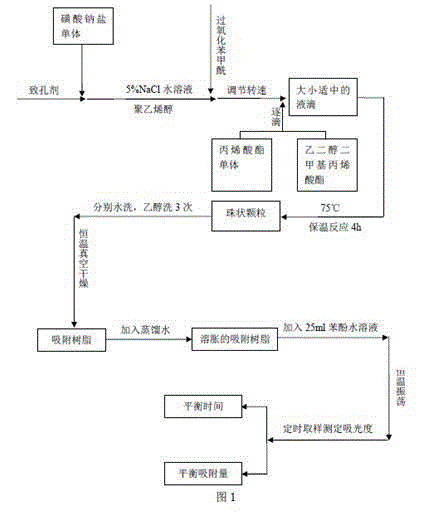

[0021] The preparation of a kind of hydrophilic acrylate adsorption resin is realized in the following way:

[0022] Weigh 4.9g of sodium chloride and add it to 90ml of distilled water to fully dissolve it, then place the aqueous solution in a three-necked reaction flask, add 0.44g of polyvinyl alcohol to the above-mentioned three-necked reaction flask, place it in a water bath and heat to 70°C , and start stirring, this system is the water phase; 4.1g sodium p-styrene sulfonate, 8ml n-heptane and 0.148g benzoyl peroxide are fully mixed and then added to a three-necked reaction flask, adjust the stirring rate, and 10.0g methyl The mixture of methyl acrylate and 0.74g ethylene glycol dimethacrylate was added dropwise (30min to complete), and when the oil droplets were uniformly dispersed and the size was moderate, the temperature was raised to 75°C, and the reaction was carried out at constant temperature for 4h; the reaction system was lowered to room temperature, Filter out t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com