Frost prevention coating and preparation method and application thereof

A coating and anti-frost technology, applied in the fields of chemical industry, energy, chemistry, and materials, can solve the problem that the anti-frost effect cannot meet the requirements, and achieve the effect of improving the normal use efficiency, excellent hydrophobicity, and excellent anti-frost performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

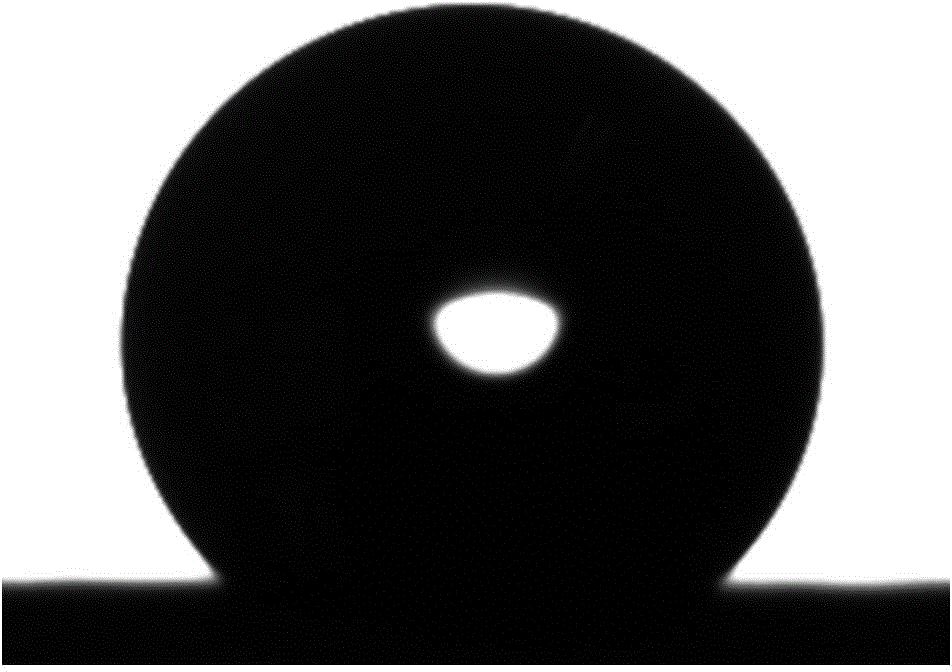

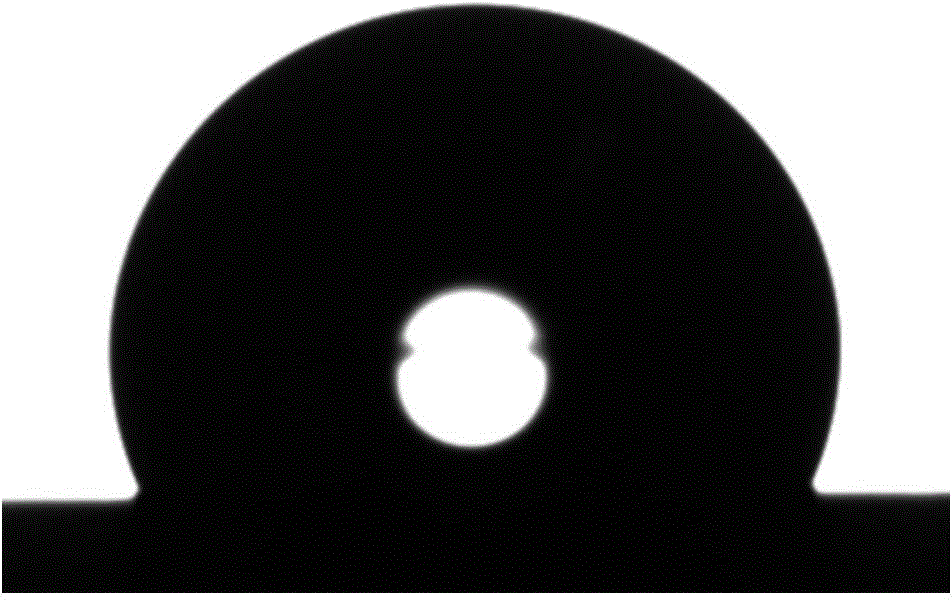

Image

Examples

Embodiment 1

[0023] The preparation method of the anti-frost coating of embodiment 1, comprises the following steps:

[0024] 1) Take 40g of hydrophobic nano-silica and 5g of dispersant BYK170, add it to a mixed solvent of 115g of butyl acetate and propylene glycol methyl ether acetate (mass ratio 2:1), and disperse by ball milling for 1h to obtain nano-silica dispersion liquid; the above-mentioned nano silicon dioxide dispersion liquid, the fluorosilicone resin SF-A35 (solid content 30%) of 400g, the mixed solvent of 80g butyl acetate and propylene glycol methyl ether acetate (mass ratio 2:1), 1g disinfectant Foaming agent BYK088, 1g rheological additive BYK405, 1.5g leveling agent BYK300, 3g leveling agent BYK399, 2g light stabilizer Tinuvin123, 1g drier dibutyltin dilaurate, 10g heptadecylfluorodecyltrimethoxysilane Mix evenly, disperse at high speed for 15 minutes, filter and discharge to obtain component A;

[0025] 2) Dilute 25g of N3390 curing agent with a mixed solvent of 75g of b...

Embodiment 2

[0027] The preparation method of the anti-frost coating of embodiment 2, comprises the following steps:

[0028]1) Take 15g of α-phase nano-alumina, 3g of dispersant TEGO Dispers 610, and 10g of heptadecafluorodecyltriethoxysilane, add them to 47g of butyl acetate, and disperse them by sand milling for 30min to obtain a nano-alumina dispersion; 100g of rutile titanium dioxide, 100g of fluorosilicone resin ETERFLON 4263 (solid content 55%) and 10g of dispersant BYK170 were added to 90g of butyl acetate, sand milled and dispersed for 15min to obtain a dispersion slurry; the above nano-alumina dispersion , dispersion slurry, 100g of fluorosilicone resin ETERFLON 4263 (solid content 55%), 13g of butyl acetate, 2g of defoamer BYK070, 1g of rheological additive BYK410, 2.5g of leveling agent BYK310, 4.5g of leveling agent BYK399 , 2g light stabilizer Tinuvin5050, 1g drier dibutyltin dilaurate, disperse at high speed for 20min, filter and discharge to obtain component A;

[0029] 2)...

Embodiment 3

[0031] The preparation method of the anti-frost coating of embodiment 3, comprises the following steps:

[0032] 1) Take 25g of α-phase nano-alumina and 5g of dispersant TEGO Dispers 610, add them to 170g of butyl acetate, sand mill and disperse for 30min, and obtain a nano-alumina dispersion; mix the above-mentioned nano-alumina dispersion, 182g of fluorosilicone resin Mix ETERFLON 4263 (solid content 55%), 110g butyl acetate, and then add 1g defoamer BYK088, 1g rheological additive BYK411, 1.5g leveling agent BYK310, 3g leveling agent BYK399, 2g light stabilizer Tinuvin292, 1g drier dibutyltin dilaurate, disperse at high speed for 20min, filter and discharge to obtain component A;

[0033] 2) Dilute 42g of N3390 curing agent with 63g of butyl acetate, filter and discharge to obtain component B;

[0034] 3) above-mentioned A component and B component are mixed, and mechanical stirring is even, obtains the anti-frost coating of embodiment 3, then the anti-frost coating of emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com