A Recycling Process of Refractory and Complex Polymetallic Ore

A polymetallic ore and refractory technology, applied in the direction of non-metallic elements, process efficiency improvement, inorganic chemistry, etc., can solve the problems of low recovery rate of valuable elements, environmental pollution, high equipment requirements, etc., to achieve clean and pollution-free process, The effect of less process hazard and less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

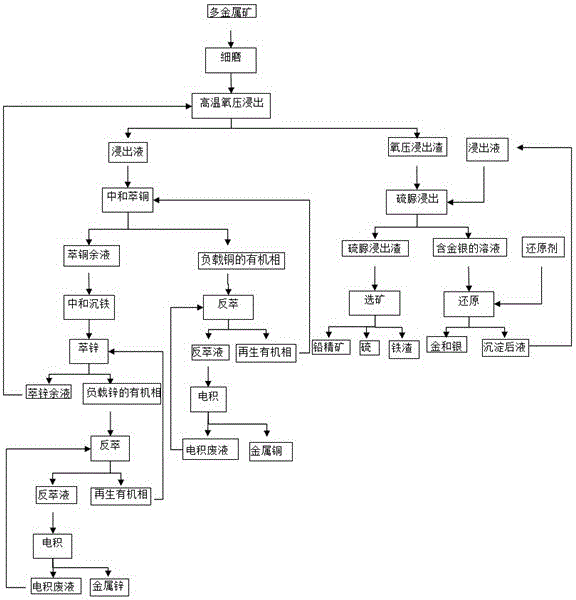

[0030] A recycling process for difficult and complex polymetallic ore, such as figure 1 As shown, including the following steps:

[0031] Step (1), oxygen pressure leaching of polymetallic ore: After ball milling the polymetallic ore, pass through a 320-mesh sieve, add the acid solution to the pressure vessel, add the material according to the mass ratio of the acid solution to the polymetallic ore at 4.5:1, then seal and pass Enter oxygen and heat and stir for leaching. Control the leaching conditions: 150~160℃, oxygen partial pressure 0.8MPa, leaching time 4h, solution pH value 1-3; after leaching is completed, filter and analyze the filter residue. Wherein, the acid solution is zinc extraction residue, in which the concentration of sulfuric acid is 80g / L;

[0032] The comprehensive leaching rates of valuable metals are respectively: Cu96.7%, Zn95.3%, Fe13.4%, and gold, silver, lead, arsenic, and sulfur are basically retained in the leaching residue. The main element content (%)...

Embodiment 2

[0046] A recycling process for difficult and complex polymetallic ore, such as figure 1 As shown, including the following steps:

[0047] Step (1), oxygen pressure leaching of polymetallic ore: After ball milling the polymetallic ore, pass through a 320-mesh sieve, add the acid solution to the pressure vessel, add the material according to the mass ratio of the acid solution to the polymetallic ore 4:1, then seal and pass Enter oxygen and heat and stir for leaching. Control the leaching conditions: 170~180℃, oxygen partial pressure 0.5MPa, leaching time 6h, solution pH value 1-3; after leaching is completed, filter and analyze the filter residue. Wherein, the acid solution is zinc extraction residue, in which the concentration of sulfuric acid is 75g / L;

[0048] The comprehensive leaching rates of valuable metals are respectively: Cu96.2%, Zn95.1%, Fe13.0%, and gold, silver, lead, arsenic, and sulfur are basically retained in the leaching residue. The main element content (%) of t...

Embodiment 3

[0062] A recycling process for difficult and complex polymetallic ore, such as figure 1 As shown, including the following steps:

[0063] Step (1), oxygen pressure leaching of polymetallic ore: After ball milling the polymetallic ore, pass through a 320-mesh sieve, add the acid solution to the pressure vessel, add the material according to the mass ratio of the acid solution to the polymetallic ore at 5:1, then seal and pass Enter oxygen and heat and stir for leaching. Control the leaching conditions: 160~170℃, oxygen partial pressure 0.2MPa, leaching time 1h, solution pH value 1-3; after leaching is completed, filter and analyze the filter residue. Wherein, the acid solution is an aqueous sulfuric acid solution, wherein the concentration of sulfuric acid is 80 g / L;

[0064] The comprehensive leaching rates of valuable metals are respectively: Cu97.5%, Zn95.8%, Fe14.1%, and gold, silver, lead, arsenic, and sulfur are basically retained in the leaching residue. The main element con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com