Method for rapidly obtaining carbon/silicon carbide coaxial fiber by reducing plasma based on microwave and application

A technology of silicon carbide and carbon fiber, which is applied in the fields of carbon fiber, fiber processing, textiles and papermaking, etc., can solve problems such as inferiority and carbon fiber diameter is too small, and achieve high efficiency, low raw material cost and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5

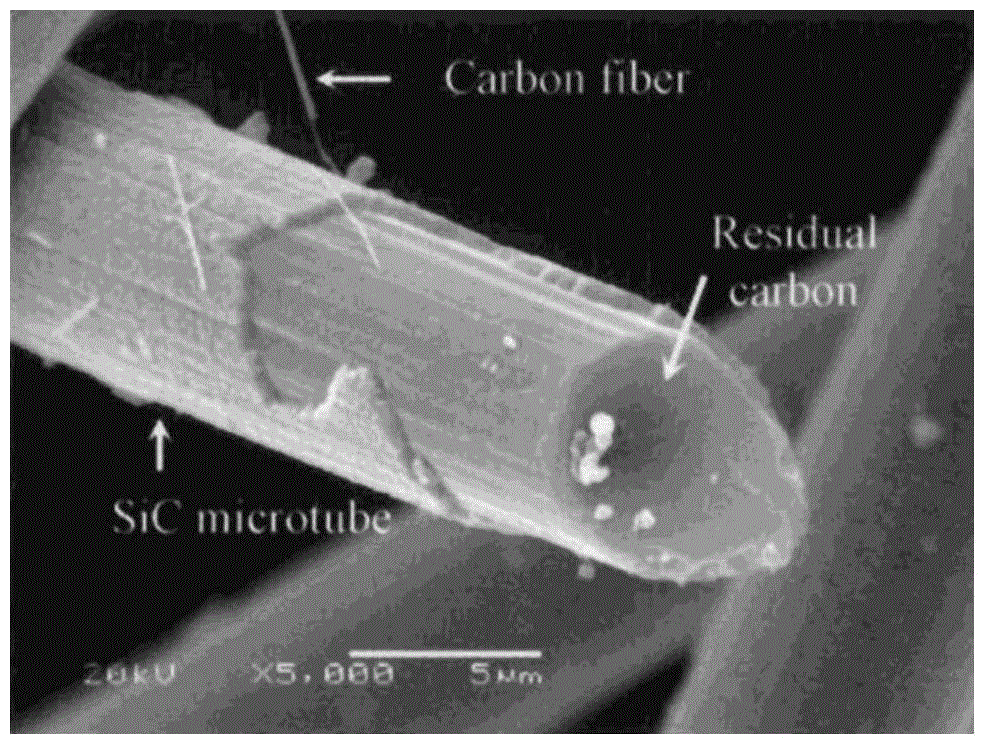

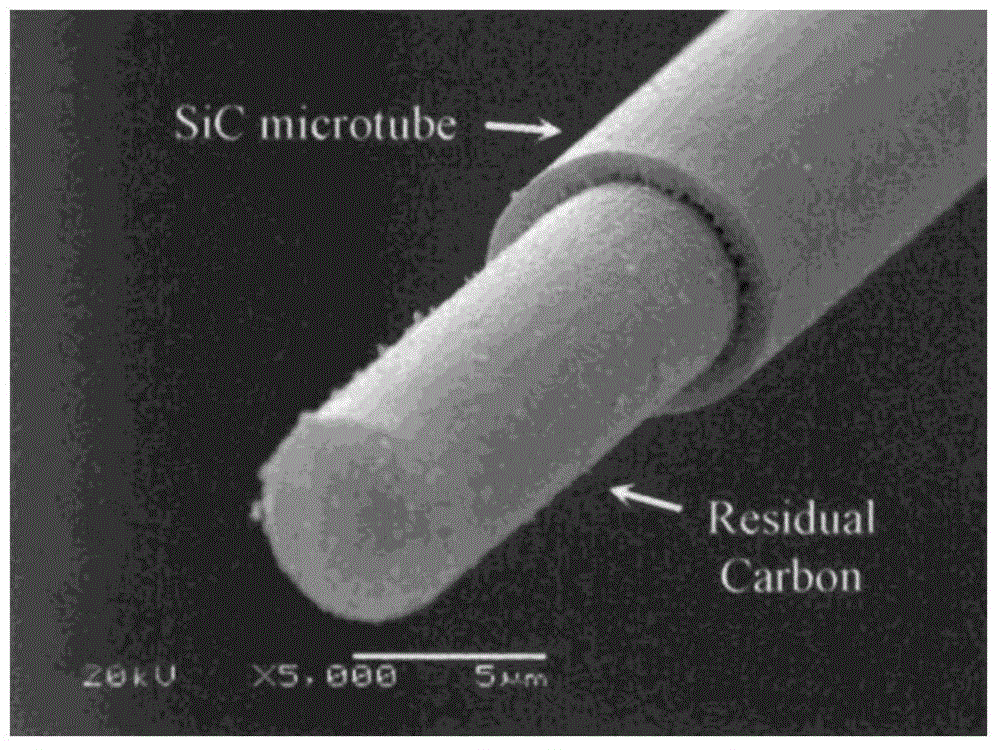

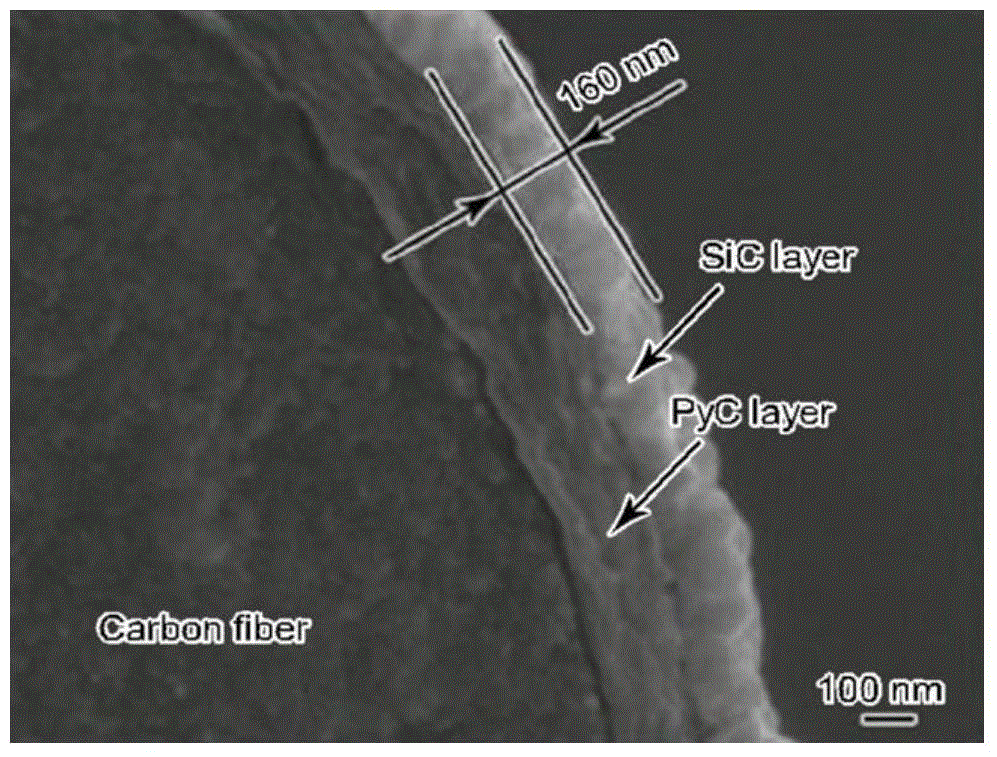

[0094] Carbon fiber and silicon powder (Si) and silicon dioxide powder (SiO2) are grown in the vapor phase 2 ) as the raw material. Carbon fiber and silicon source are pressed carbon / silicon element mol ratio C:Si=5:1, the mol ratio Si of silicon / silicon dioxide in the silicon source:SiO 2 = 2:1 ratio of ingredients, mixed and placed in the resonant cavity of the microwave oven. First vacuumize to about 25KPa, then apply 5.5kW microwave, the sample temperature rises rapidly to about 1245°C. After 10 seconds of continuous irradiation, the C / SiC coaxial fiber is obtained.

[0095] Tests on the high-temperature thermal oxidation characteristics of C / SiC coaxial fibers show that the initial oxidation temperature is about 781°C; the thermal weight loss of fibers in the range of 810-915°C changes relatively quickly, but still has obvious protection for the carbon fiber core. Effect. Continuous thermal oxidation at a high temperature above 1105-1436 °C degrades the protection abi...

Embodiment 6

[0098] T800 type polyacrylonitrile (PAN) based carbon fiber and silicon powder (Si) and silicon dioxide powder (SiO 2 ) as the raw material. Carbon fiber and silicon source are pressed carbon / silicon element mol ratio C:Si=4:1, the mol ratio Si:SiO of silicon / silicon dioxide in the silicon source 2 = 1:1 ratio of ingredients, mixed and placed in the resonant cavity of the microwave oven. First vacuumize to about 30Pa, then apply 3.5kW microwave, the sample temperature rises rapidly to about 1190℃. After 40 seconds of continuous irradiation, the C / SiC coaxial fiber is obtained.

[0099] Tests on the high-temperature thermal oxidation characteristics of C / SiC coaxial fibers showed that the initial oxidation temperature increased to 781°C, and the weight increased slightly; the rapid thermal weight loss temperature range was delayed to 827-945°C; High temperature continuous thermal oxidation, relative to the oxidation of carbon fiber, the residual rate of coaxial fiber is abou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com