Method for welding silicon wafer and molybdenum piece in semiconductor device and application of silicon wafer and molybdenum piece

A semiconductor and silicon wafer technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical solid-state devices, etc., can solve the problems of large ohmic contact between silicon wafers and molybdenum wafers, reduced ohmic contact effect, and reduced component life, etc., to improve The effect of anti-surge current ability and firmness, small contact thermal resistance and transient thermal impedance, good thermal conductivity and electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method comprising the following steps is adopted to prepare a soldered product of a silicon wafer / molybdenum wafer in a semiconductor device:

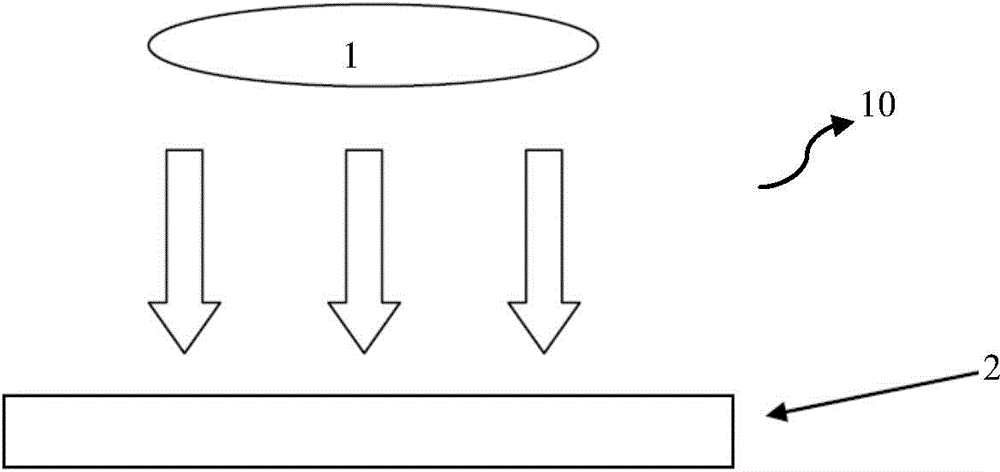

[0048] a. Sputter silver on one side of the molybdenum sheet, and the thickness of the first silver layer obtained by sputtering is 0.5 μm;

[0049] b. Sputtering titanium, nickel and silver sequentially on the anode surface of the silicon wafer. The thicknesses of the obtained titanium layer, nickel layer and second silver layer are successively 0.1 μm, 0.5 μm and 1 μm;

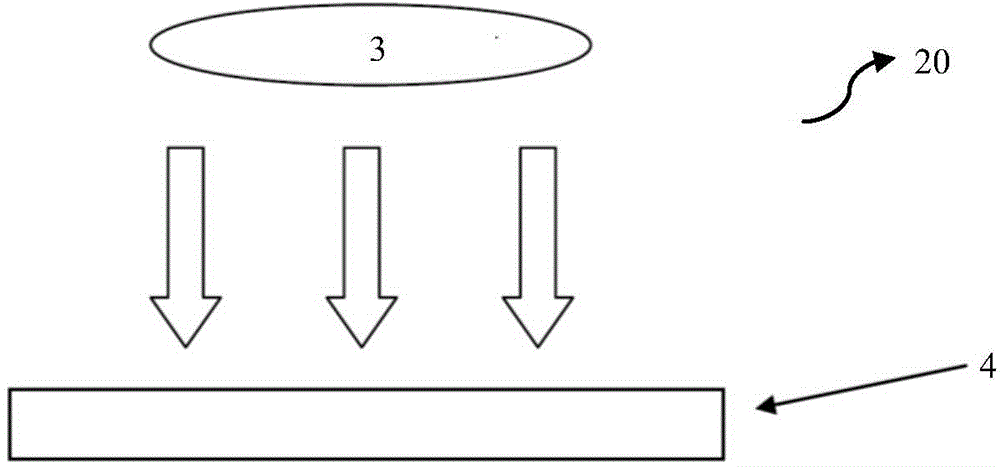

[0050] c. Transfer nano-silver to the first silver layer under the process conditions of 150°C and 0.3MPa, and remove the supporting material polytetrafluoroethylene film of the nano-silver layer, and then contact the second silver layer;

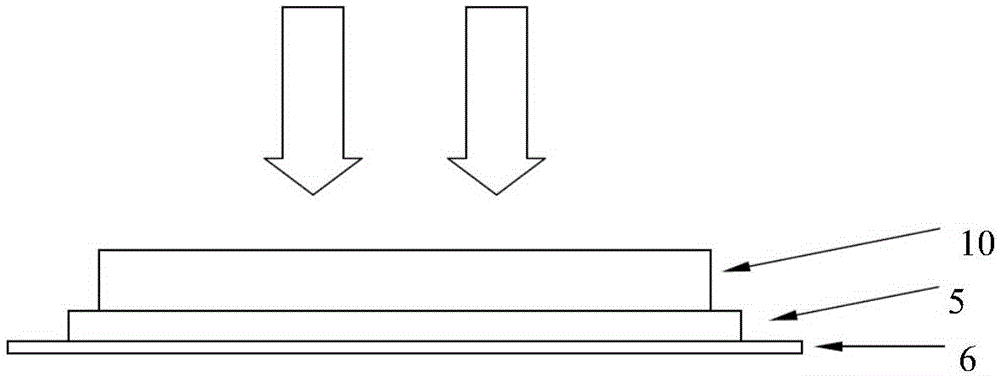

[0051] d. Under the process conditions of 250°C and 15MPa, the welding is realized, the process time is about 2 minutes, and then slowly cooled by natural cooling. Graphite is used as a buffer layer on the cathode side ...

Embodiment 2

[0054] A method comprising the following steps is adopted to prepare a soldered product of a silicon wafer / molybdenum wafer in a semiconductor device:

[0055] a. Sputter silver on one side of the molybdenum sheet, and the thickness of the first silver layer obtained by sputtering is 0.4 μm;

[0056] b. Sputtering titanium, nickel and silver sequentially on the anode surface of the silicon wafer. The thicknesses of the obtained titanium layer, nickel layer and second silver layer are successively 0.2 μm, 0.5 μm and 1.1 μm;

[0057] c. Transfer nano-silver to the first silver layer under the process conditions of 150°C and 0.3MPa, and remove the supporting material polytetrafluoroethylene film of the nano-silver layer, and then contact the second silver layer;

[0058] d. Under the process conditions of 300°C and 15MPa, the welding is realized, the process time is about 2 minutes, and then slowly cooled by natural cooling. Graphite is used as a buffer layer on the cathode sid...

Embodiment 3

[0061] A method comprising the following steps is adopted to prepare a soldered product of a silicon wafer / molybdenum wafer in a semiconductor device:

[0062] a. Sputter silver on one side of the molybdenum sheet, and the thickness of the first silver layer obtained by sputtering is 0.5 μm;

[0063] b. Sputtering titanium, nickel and silver sequentially on the anode surface of the silicon wafer. The thicknesses of the obtained titanium layer, nickel layer and second silver layer are successively 0.1 μm, 0.5 μm and 1 μm;

[0064] c. Transfer nano-silver to the first silver layer under the process conditions of 150°C and 0.3MPa, and remove the supporting material polytetrafluoroethylene film of the nano-silver layer, and then contact the second silver layer;

[0065] d. Under the process conditions of 250°C and 10MPa, welding is realized, the process time is about 2 minutes, and then slowly cooled by natural cooling. Graphite is used as a buffer layer on the cathode side of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com