Vanadium cell, vanadium cell end collector plate, vanadium cell dual collector plate and preparation of vanadium cell end collector plate and vanadium cell dual collector plate

A vanadium battery and current collector technology, applied in fuel cells, regenerative fuel cells, fuel cell components, etc., can solve the problems of reduced machinability, reduced mechanical properties of products, etc., and achieves improved graphitization degree and reactivity. The effect of increasing and simplifying the operation is dangerous

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

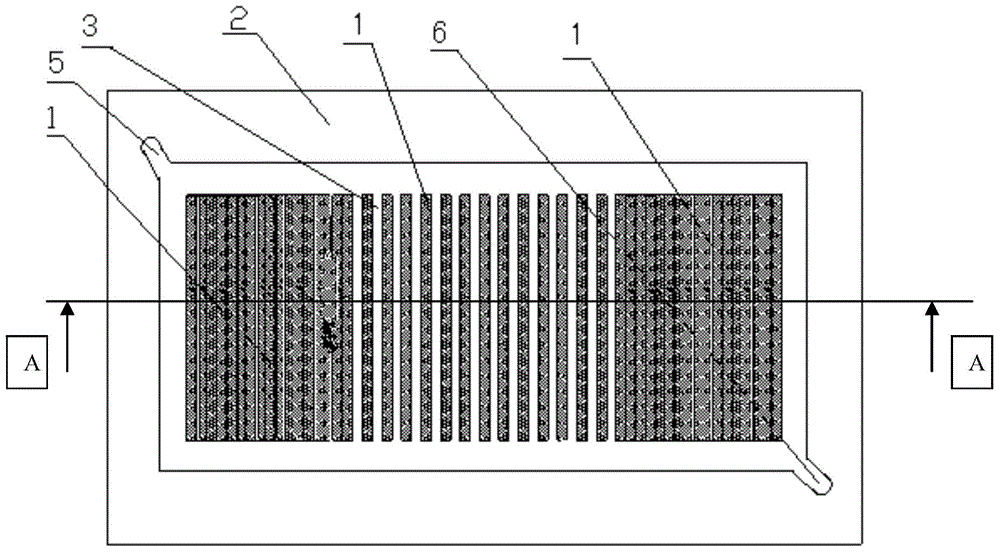

[0035] The first technical problem solved by the present invention is to provide a method for preparing a vanadium battery double collector plate, comprising the following steps:

[0036] a. Curable resin pretreatment: add acetone to the curable resin and mix it evenly, and then mix it with the curing agent, wherein the volume ratio of the curable resin to acetone is 1 / 4-1 / 2;

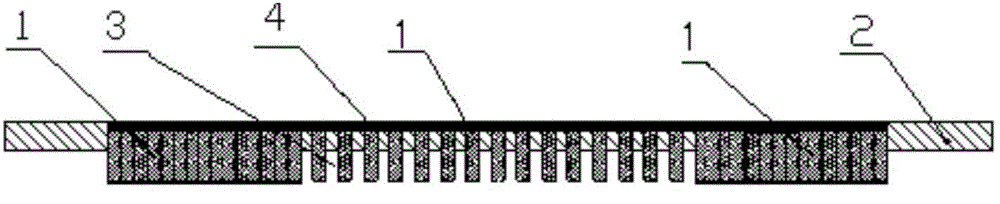

[0037] b. Curing treatment: put the first activated carbon fiber felt in the mold, add the pretreated curable resin, and cure at room temperature so that the curable resin is not completely solidified; the thickness of the curable resin layer is 0.8-1.7cm;

[0038] c. Secondary curing: Place the second activated carbon fiber felt on the first activated carbon fiber felt after curing treatment, and pressurize and cure under the pressure of 1.5-5 kPa at room temperature for 24-48 hours to obtain the double current collector of the vanadium battery plate;

[0039] Wherein, the first activated carbon fiber...

Embodiment 1

[0066] Soak the carbon felt strip in sulfuric acid with a pH of 2 for 24 hours, then ultrasonically treat it with a frequency of 30khz for 30 minutes, take it out after cooling, wash it with distilled water for 3-4 times, and place it in an electric furnace at a temperature of 100-200°C Dry activated carbon felt strips.

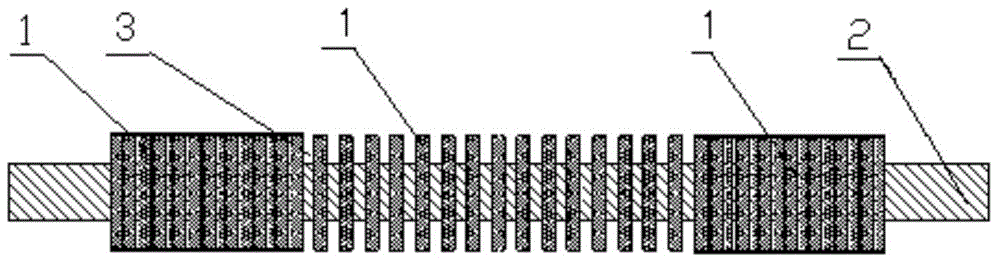

[0067] First take a slice of the above-mentioned activated carbon felt and place it in the mold (the mold can be selected according to the size of the battery and the size and position of the carbon felt strip), add the diluted epoxy resin of the grade E-44, and place it in the mold at room temperature. After curing at room temperature for 10 hours, cure at room temperature so that the curable resin is in an incompletely solidified state; then place another carbon felt strip at the place corresponding to the carbon felt strip before, and apply a pressure of 1 kPa on the mold , pressurized and solidified at room temperature for 35 hours to obtain a double coll...

Embodiment 2

[0071] Soak the carbon felt strip in sulfuric acid with a pH of 3 for 19 hours, then ultrasonically treat it with a frequency of 50khz for 20 minutes, take it out after cooling, wash it with distilled water for 3-4 times, and place it in an electric furnace at a temperature of 100-200°C Dry activated carbon felt strips.

[0072] First place the copper sheet in the mold, add the diluted epoxy resin of grade E-44 (the diluent is acetone, and the volume ratio of the diluent to the epoxy resin is 1 / 4), and cure at room temperature for 9 hours Finally, put the corresponding carbon felt strip at the place corresponding to the position of the double current collector carbon felt strip obtained in the above-mentioned embodiment 1, and apply a pressure of 1.1 kPa on the mold, and pressurize and solidify at room temperature for 38 Hours, take out and polish the copper sheet with sandpaper until the polymer material attached to it is completely removed.

[0073] Cast the above-mentioned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Coulombic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com