High-effective lignosulfonate pesticide suspension dispersing agent and preparation and applications thereof

A technology of lignosulfonate and dispersant, applied in application, biocide, animal repellent, etc., can solve the problems of unclear process parameters, poor performance, high cost, and achieve favorable interaction and improve dispersion performance. , the effect of improving the dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Dissolve 10g of alkali lignin in 20mL of water, add 2g of NaOH, adjust the pH to 12, and add 1g of 1,4-butyl sultone and 1g of 1,6-dibromohexane at the same time. The reaction was conducted under heating at ℃ for 8 hours; after the reaction, it was cooled to room temperature, and the lignosulfonate product (lignosulfonate high-efficiency pesticide suspension dispersant) was obtained after purification.

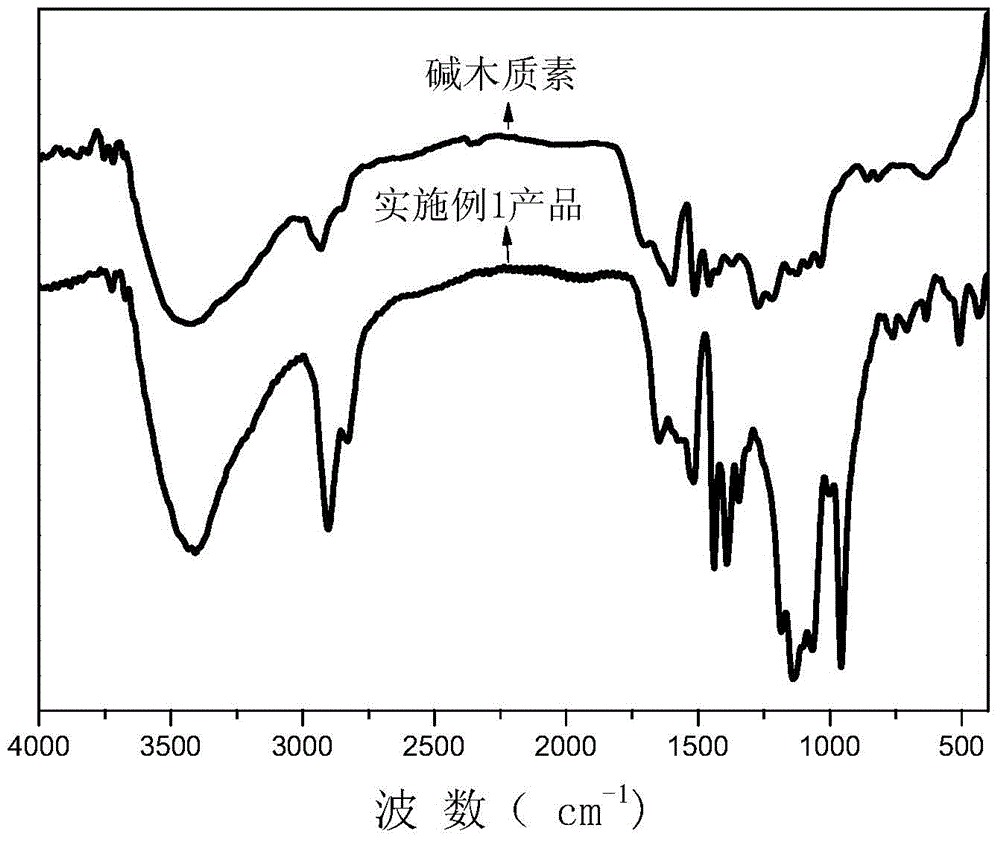

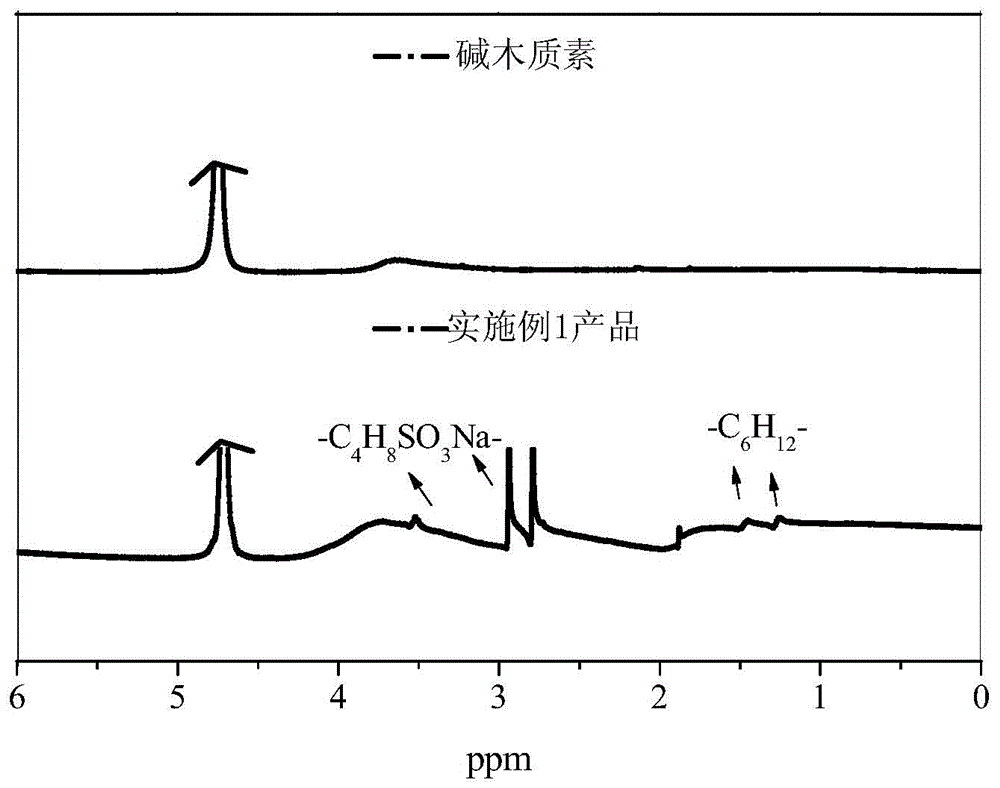

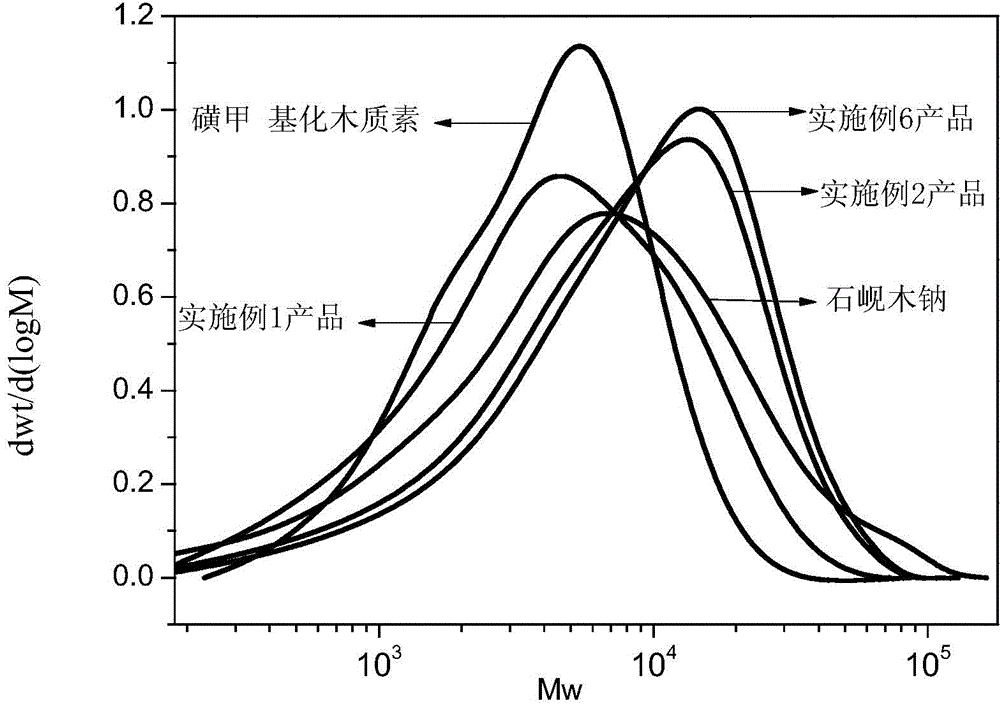

[0042] In the experiment, the instrument AutosystemXL / I-series / Spectrum2000 infrared spectrometer was used, and the potassium bromide tablet method was used to perform infrared characterization of the alkali lignin and the product of this example. Such as figure 1 As shown, 2935cm -1 There is a methylene stretching vibration peak, which is obviously enhanced; 1160cm -1 Where is the stretching vibration peak of the ether bond, the absorption strength of the product of Example 1 has been significantly improved, and the absorption peak of the sulfonate group is 1217 cm -1...

Embodiment 2

[0048] Dissolve 10g alkali lignin in 30mL ethanol, add 1.5g KOH, adjust the pH to 12, and add 1.5g 1,3-propyl sultone and 2g 1,5-dibromopentane dropwise at normal pressure. , Reaction at room temperature for 8h; after the reaction, the lignosulfonate product is obtained after purification.

Embodiment 3

[0050] Dissolve 10g alkali lignin in 30mL methanol and add 2g Na 2 CO 3 , Adjust the pH to 14, and at the same time add dropwise 2g 1,4-butane sultone and 2g 1,10-dibromodecane, and react for 8h under normal pressure and heating at 80℃; after the reaction, cool to room temperature, After purification, lignosulfonate products are obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Degree of sulfonation | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com