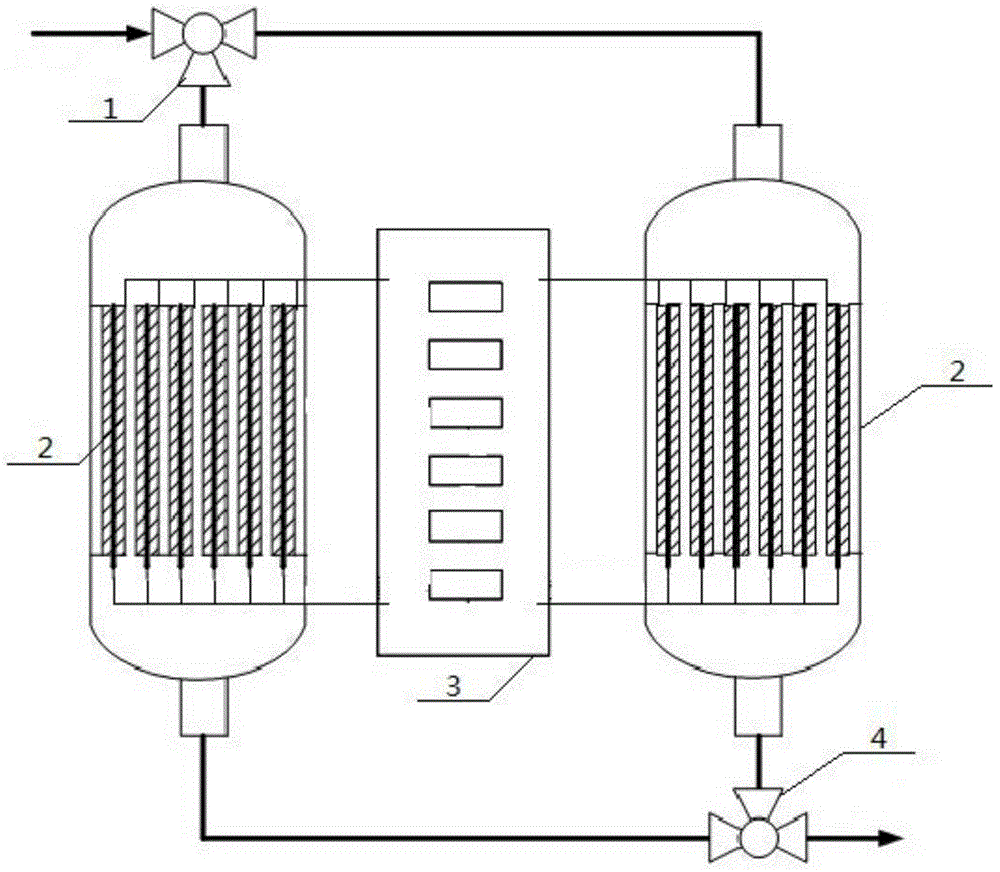

Matrix type dielectric barrier plasma synergistic adsorption/catalytic decomposition denitration device

A plasma and dielectric barrier technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., to achieve the effects of simple devices, reduced energy loss, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

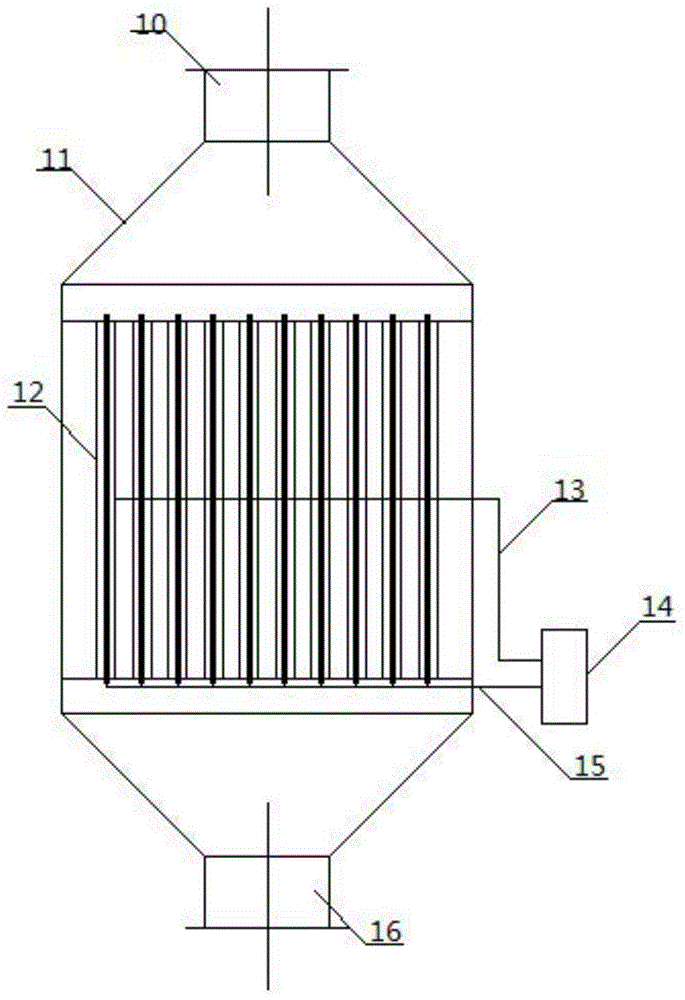

[0025] 15% Cu-CMS is used as the catalyst filling layer 8 . A quartz tube with a diameter of 10mm and a length of 25cm is used as the quartz tube reactor 6, a 3mm copper rod is used as the high voltage electrode 5, and an aluminum foil is used as the ground electrode 7. Take an appropriate amount of 15% Cu-CMS and place it in the reaction system, the flow rate is 300ml / min containing 0.05% NO, 2.8% O 2 , N 2 The mixed gas used as the balance gas is passed into the reaction device, and the ventilation is stopped after 20 minutes of adsorption, and the low-temperature plasma cooperative decomposition reaction is carried out. The plasma output voltage is 7.8KV, the frequency is 8.9KHz, and the discharge time is 10 minutes. Stop. Then repeat the above operation 4 times, single NO x The removal rate was 95%.

Embodiment 2

[0027] A copper-modified activated carbon is used as the catalyst packing layer 8 . A quartz tube with a diameter of 50mm and a length of 30cm is used as the quartz tube reactor 6, an 8mm copper tube is used as the high voltage electrode 5, and copper foil is used as the ground electrode 7. Take an appropriate amount of 10% Cu-AC and place it in the reaction system, pass the mixed gas with a flow rate of 3000ml / min containing 0.05% NO, and air as the balance gas into the reaction device, stop the ventilation after 30 minutes of adsorption, and carry out the low-temperature plasma cooperative decomposition reaction. The plasma output voltage is 7.8KV, the frequency is 8.9KHz, and the discharge time stops after 20min. Then repeat the above operation 3 times, single NO x The removal rate was 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com