Tin dioxide multi-stage structured nanosphere carbon dioxide electrochemical reduction catalyst, preparation method and application of tin dioxide multi-stage structured nanosphere carbon dioxide electrochemical reduction catalyst

A technology of tin dioxide and carbon dioxide, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the unreported and electrochemical reduction effects of electrochemical reduction It has not received widespread attention and other issues, and achieved the effect of reducing hydrogen evolution reaction and catalyst passivation effect, good application prospects, and reducing hydrogen evolution side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

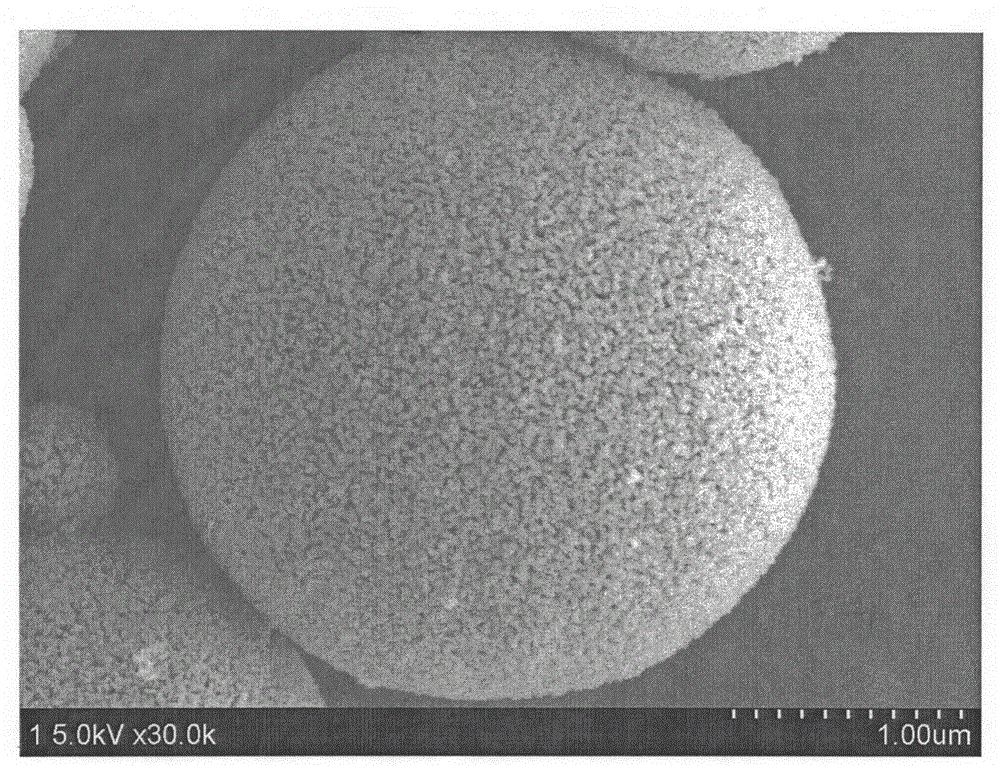

[0026] SnO 2 Preparation of multi-level nanosphere catalyst precursor: Take 12mM glucose (monohydrate) and 3mM tin tetrachloride and mix and dissolve in a mixed solution with a volume ratio of 5:30~30:5 ethanol / deionized water to form a colorless and transparent solution to get SnO 2 Hierarchical nanosphere catalyst precursor.

Embodiment 2

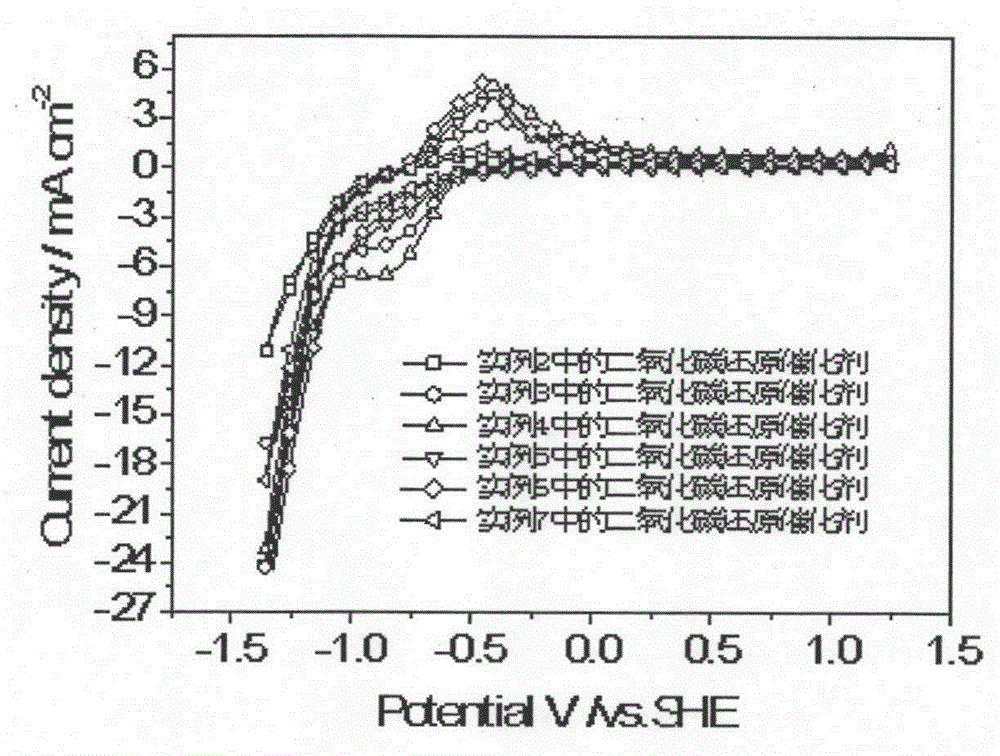

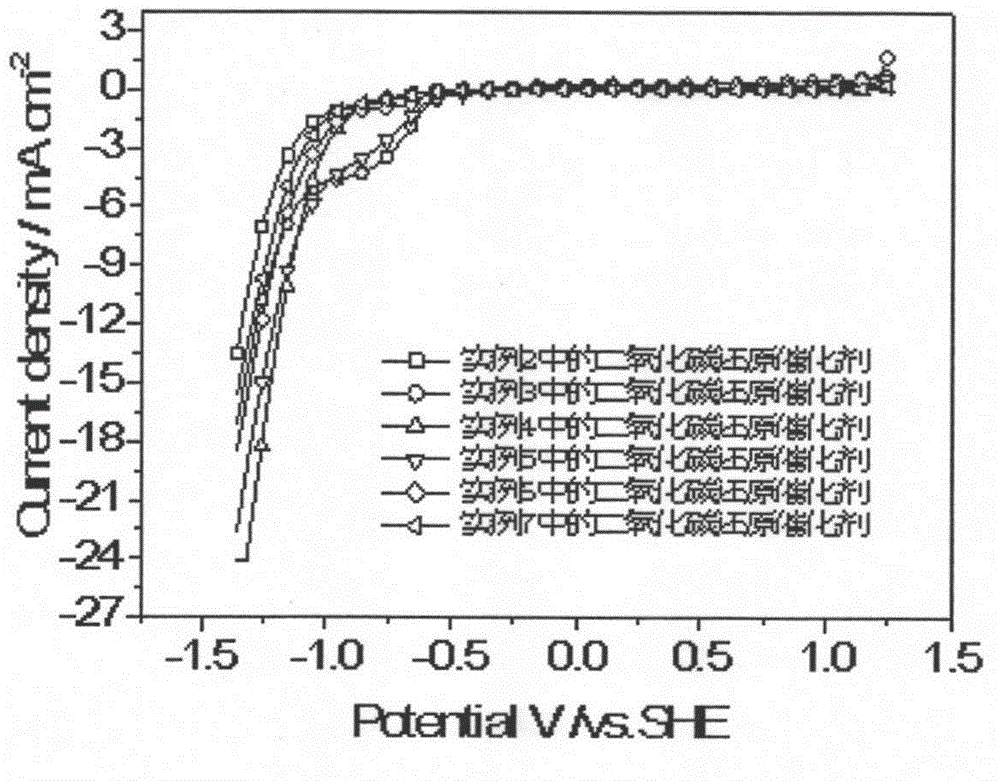

[0028] A carbon dioxide electrochemical reduction catalyst, comprising tin dioxide multi-level structure nanospheres, said tin dioxide multi-level structure nanospheres are synthesized by hydrothermal reaction, and its preparation method is: take 12mM glucose (monohydrate) and 3mM Tin tetrachloride is mixed and dissolved in 0ml deionized water and 35mL ethanol to form a colorless and transparent solution to obtain SnO 2 Hierarchical nanosphere catalyst precursor, and moved into a 100mL reactor. The reaction kettle is a hydrothermal reaction kettle with a polytetrafluoroethylene liner and a stainless steel jacket. The reaction kettle is placed in an oven at 190°C for hydrothermal reaction for 24 hours, centrifuged, and washed with ethanol and deionized water respectively. After vacuum drying at 50°C for 5 hours, continue to burn in a muffle furnace at 600°C for 4 hours to obtain carbon dioxide electrochemically reduced SnO 2 Hierarchical nanosphere (100% Et) catalyst.

Embodiment 3

[0030]A carbon dioxide electrochemical reduction catalyst, comprising tin dioxide multi-level structure nanospheres, said tin dioxide multi-level structure nanospheres are synthesized by hydrothermal reaction, and its preparation method is: take 12mM glucose (monohydrate) and 3mM Tin tetrachloride is mixed and dissolved in 5ml deionized water and 30mL ethanol to form a colorless and transparent solution to obtain SnO 2 Hierarchical nanosphere catalyst precursor, and moved into a 100mL reactor. The reaction kettle is a hydrothermal reaction kettle with a polytetrafluoroethylene liner and a stainless steel jacket. The reaction kettle is placed in an oven at 190°C for a hydrothermal reaction for 24 hours, centrifuged, cleaned with ethanol and deionized water, 50 After vacuum drying at ℃ for 5 hours, continue to burn in a muffle furnace at 600℃ for 4 hours to obtain carbon dioxide electrochemically reduced SnO 2 Hierarchical nanospheres (14%H 2 O-86%Et) catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com