Magnetic ZnO/Fe3O4 catalyst as well as preparation method and application thereof

A composite catalyst and reaction technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of low pollutant removal efficiency and long reaction time, etc. To achieve the effect of simple preparation method, short synthesis process cycle and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

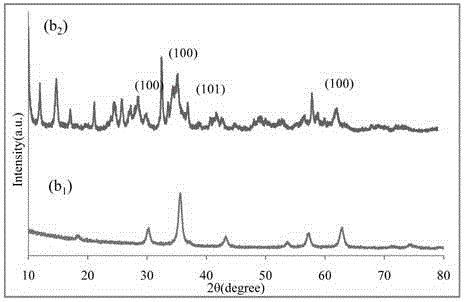

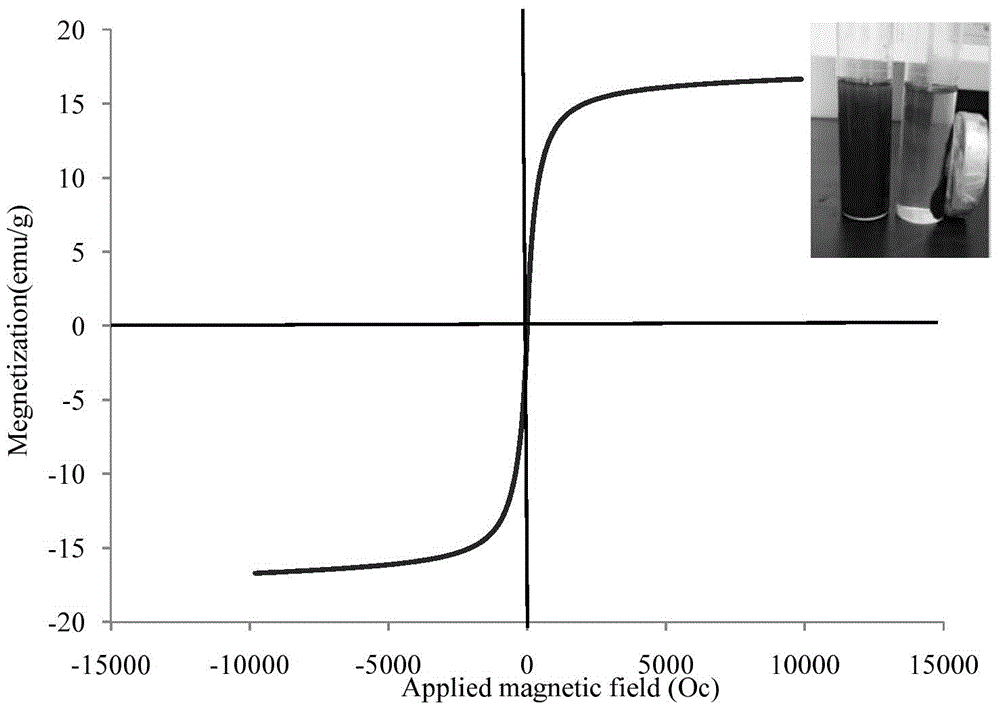

[0053] 1) Preparation of Fe 3 o 4 :

[0054] Weigh 0.0172molFeCl 3 ·6H 2 O, 0.0086mol FeSO 4 ·7H 2 O was dissolved in 400mL ultrapure water, and N 2 Then stir well.

[0055] Slowly add 0.1mol NH to the above solution dropwise 3 ·H 2 O, continue stirring for 30min to obtain a black precipitate, which is washed to neutrality with ultrapure water and separated with a magnet to obtain magnetic Fe 3 o 4 .

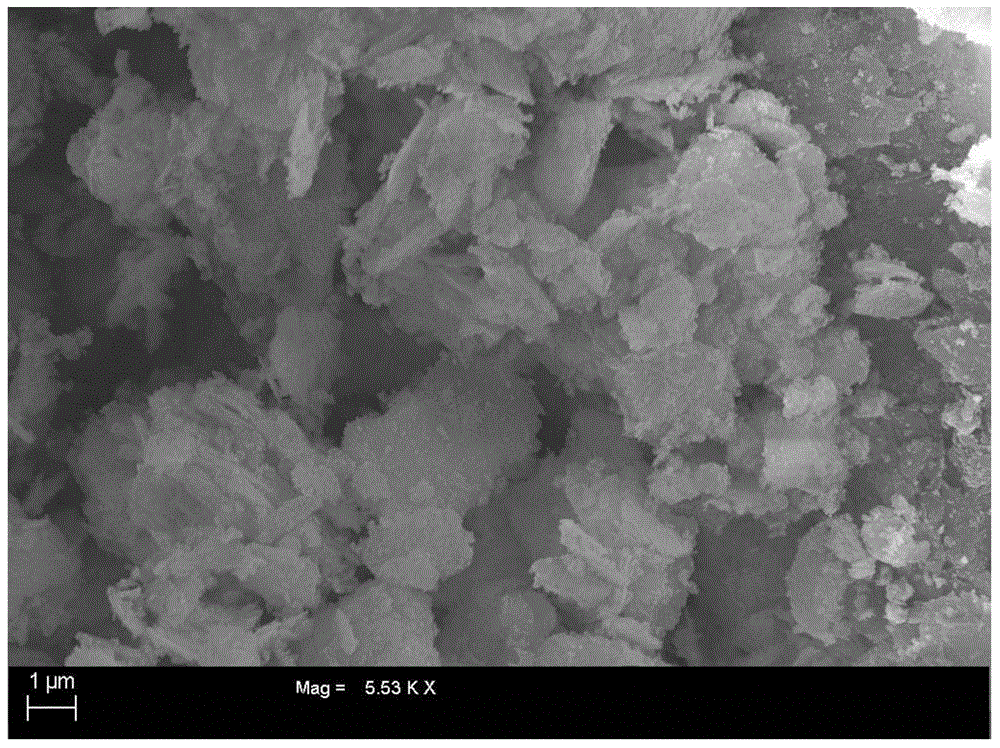

[0056] 2) Preparation of Zn 0 / Fe 3 o 4 Composite catalyst:

[0057] With the freshly prepared Fe obtained in step 1) 3 o 4 (0.026mol) dispersed in 200mL ultrapure water, add 0.052mol ZnSO 4 , into N 2 Then stir well. Add 400mL 0.269mol / L NaBH dropwise to the above solution 4 After fully performing the reduction reaction at 20°C for 30 minutes, the obtained reaction system was centrifuged, and the obtained precipitate was washed with water until the pH value was neutral, and then dried at 50°C for 24 hours to obtain the Zn 0 / Fe 3 o 4 Composite catalyst. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com