Hydrogen type germanium-silicon molecular sieve with ZSM-5 structure and preparation method thereof

A ZSM-5, molecular sieve technology, applied in the field of hydrogen-type germanium-silicon molecular sieve and its preparation, can solve the problems of few instances, etc., and achieve the effects of high crystallinity, controllable grain size and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] Mix 7g of germanium dioxide, 48.9g of tetrapropylammonium bromide (TPABr), 12.2g of n-butylamine and 360ml of deionized water evenly, add 20g of solid silica gel under stirring, stir vigorously, age at 25°C for 2h, and then transfer to the reaction Kettle, hydrothermal crystallization at 160°C for 4 hours, cooling to 100°C for hydrothermal crystallization for 8 hours, then heating up to 180°C for 12 hours.

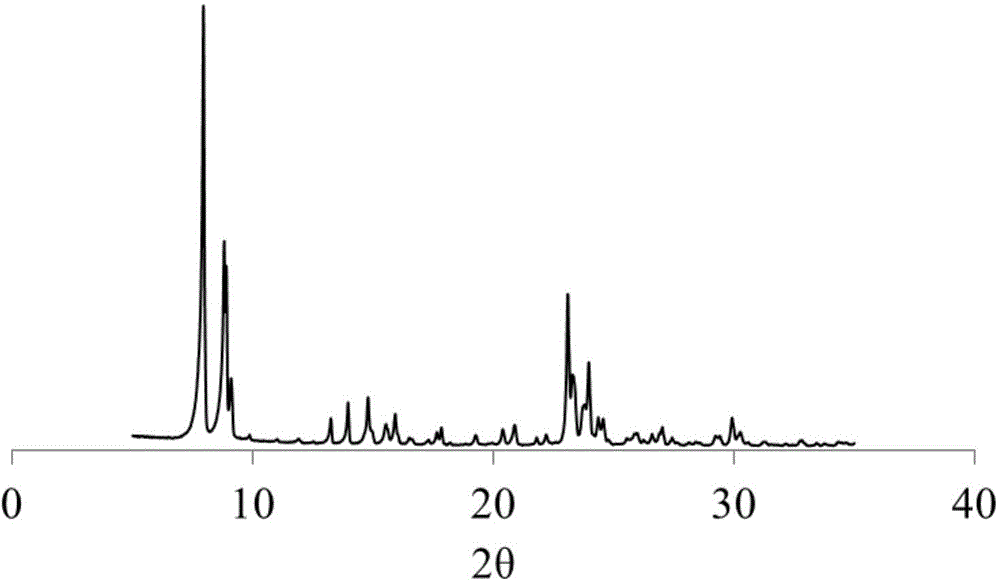

[0028] After hydrothermal crystallization, quickly cool to 30°C, the reaction product is centrifuged, the obtained solid is washed with water until the pH of the washing solution is 8-9, and dried at 100°C for 12 hours to obtain hydrogen with a crystal phase of ZSM-5 structure Type germanium silicon molecular sieve GZ-1, its X-ray powder diffraction pattern is shown in figure 1 , the anhydrous chemical composition (in oxide molar ratio) is: GeO 2 15.6SiO2 2 , the relative crystallinity is 92%, and the grain size is 3.5μm.

example 2

[0030] Mix 1.4g of germanium dioxide, 48.9g of tetrapropylammonium bromide, 12.2g of n-butylamine and 360ml of deionized water evenly, add 20g of solid silica gel under stirring, stir vigorously, age at 25°C for 2h, and then move it into the reaction kettle. It was hydrothermally crystallized at 150°C for 6 hours, cooled to 120°C for 6 hours, and then heated to 180°C for 12 hours.

[0031] After hydrothermal crystallization, quickly cool to 30°C, the reaction product is centrifuged, the obtained solid is washed with water until the pH of the washing solution is 8-9, and dried at 100°C for 12 hours to obtain hydrogen with a crystal phase of ZSM-5 structure Type germanium silicon molecular sieve GZ-2, its anhydrous chemical composition (calculated by oxide molar ratio) is: GeO 2 40.3SiO2 2 , the relative crystallinity is 93%, and the grain size is 2.3μm.

example 3

[0033] Mix 0.7g of germanium dioxide, 48.9g of tetrapropylammonium bromide, 12.2g of n-butylamine and 360ml of deionized water evenly, add 20g of solid silica gel under stirring, stir vigorously, age at 25°C for 2h, and then transfer to the reaction kettle. It was hydrothermally crystallized at 140°C for 8 hours, cooled to 120°C for 6 hours, and then heated to 180°C for 10 hours.

[0034] After hydrothermal crystallization, quickly cool to 30°C, the reaction product is centrifuged, the obtained solid is washed with water until the pH of the washing solution is 8-9, and dried at 100°C for 12 hours to obtain hydrogen with a crystal phase of ZSM-5 structure Type germanium silicon molecular sieve GZ-3, its anhydrous chemical composition (calculated by oxide molar ratio) is: GeO 2 72.6SiO2 2 , the relative crystallinity is 93%, and the grain size is 1.8μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com