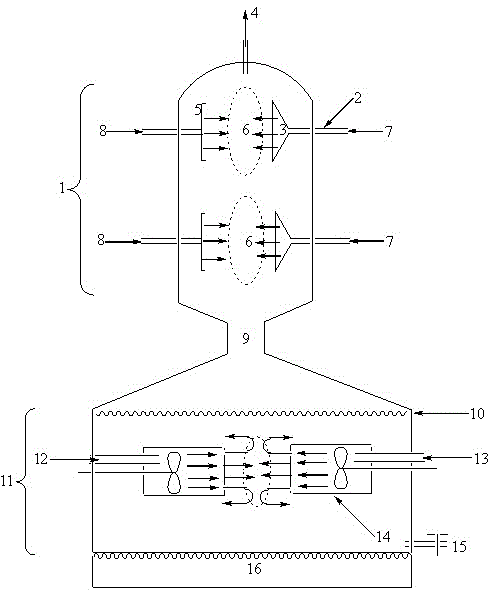

Impinging stream reactor

An impinging flow reactor and reactor technology, applied in chemical instruments and methods, inorganic chemistry, alkali metal aluminate/aluminum oxide/aluminum hydroxide preparation, etc., can solve problems such as single method, increase reaction area, The effect of uniform growth of particles and uniform dispersion of grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add bottom water to the bottom of the gas-liquid impingement flow reactor, and heat to 90°C; start the impingement flow reactor, and adjust the frequency of the ultrasonic generator to 30KHZ. Adjust the impact direction of the two acceleration tubes to be horizontal, start the accelerator, inject the alkali metal aluminate aqueous solution with a concentration of 30g / 100mL at a flow rate of 15L / h from the feed port I, and atomize the liquid through the pressure atomization nozzle The CO injected by the accelerator tube at the air inlet level with it at a flow rate of 10L / h 2 Collide with each other, react for 1.0h, stop injecting gas and liquid and the ultrasonic generator at the bottom; at the same time, add sodium metaaluminate solution and aluminum sulfate continuously at 0.6L / min to the feed ports II and III at the bottom of the impact flow reactor solution, adjust the pH value to 7.5, and after 15 minutes of neutralization reaction, stop feeding the feed port; rais...

Embodiment 2

[0029] Add bottom water to the bottom of the gas-liquid impingement flow reactor and heat to 80°C; start the impingement flow reactor and adjust the frequency of the ultrasonic generator to 50kHz. Adjust the impact direction of the two acceleration tubes to be horizontal, start the accelerator, inject the alkali metal aluminate aqueous solution with a concentration of 25g / 100mL at a flow rate of 10L / h from the feed port I, and atomize the liquid through the pressure atomization nozzle The CO injected by the accelerator tube at the air inlet level with it at a flow rate of 10L / h 2 Collide with each other, react for 1.0h, stop injecting gas and liquid and the ultrasonic generator at the bottom; at the same time, add sodium metaaluminate solution and aluminum sulfate continuously at 0.8L / min to the feed ports II and III at the bottom of the impingement flow reactor solution, adjust the pH value to 7.0, and after 10 minutes of neutralization reaction, stop feeding the feed port; r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com