Recycling method of unfused zircon sand in technical process for preparing zirconium oxychloride by alkaline fusion method

A zirconium oxychloride and process technology, which is applied in the field of recycling of unfused zircon sand, can solve the problem that the recycling rate of unfused zircon sand has not yet been seen, hinders the development of zirconium oxychloride industry, oxygen The problems of reducing the yield of zirconium chloride, etc., achieve the effects of being beneficial to environmental protection, saving zircon sand resources, and improving the utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

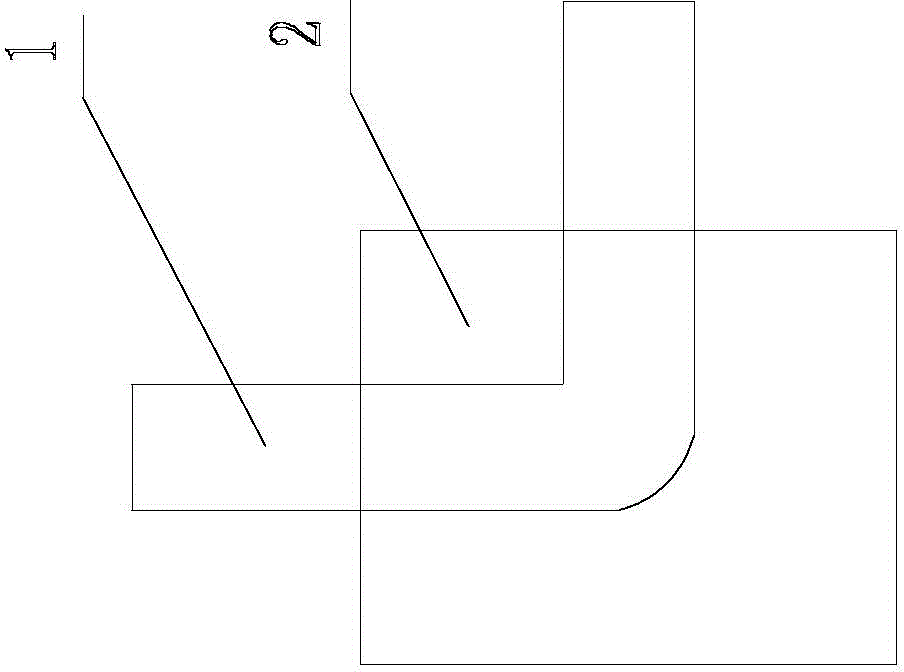

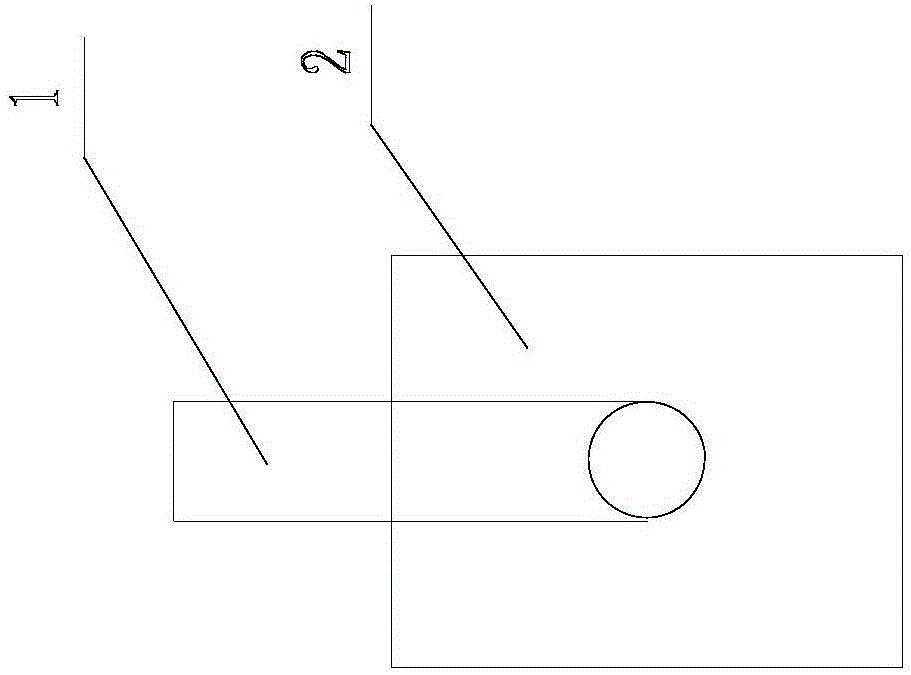

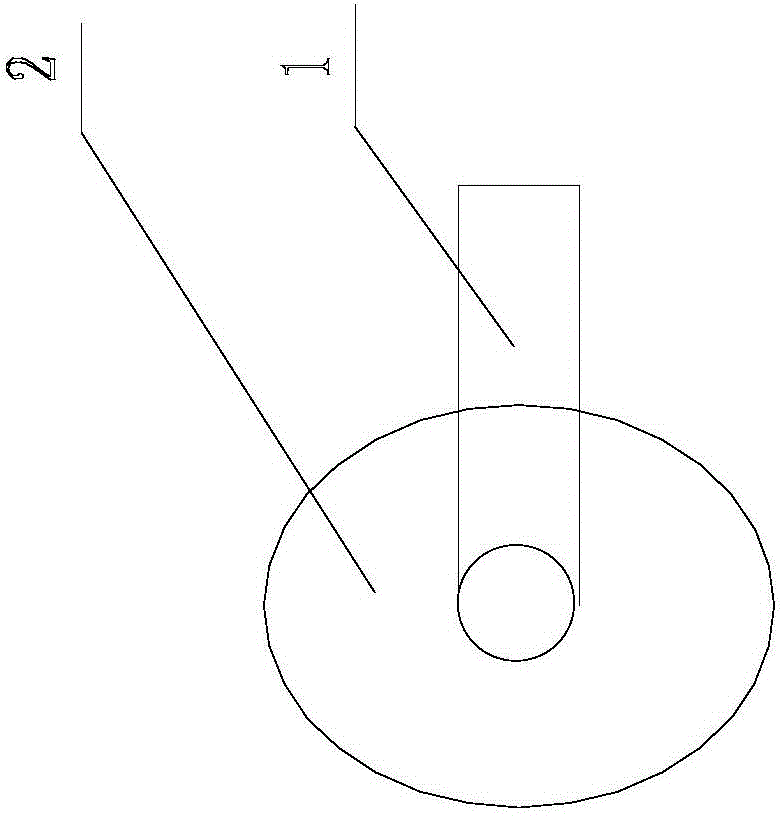

Image

Examples

Embodiment 1

[0064] The invention provides a method for recycling unfused zircon sand in the process of preparing zirconium oxychloride by an alkali fusion method. After the water washing and transformation section and before the acidification section, an unfused zircon sand recovery process is added, and the unmelted zircon sand is recovered. Zircon sand is precipitated and separated from the dilute hydrochloric acid solution transferred from water; the operation steps are as follows:

[0065] ①. Dilute hydrochloric acid dissolved water transfer material

[0066] In the dilute hydrochloric acid dissolving reactor, 1 ton of water is transferred to the material (the zirconium content is 40%, according to the alkali hydrolysis rate of 98%, it is converted into 0.628 tons of 65% zircon sand) according to the water transfer: dilute hydrochloric acid (mass ratio) = The ratio of 1:3 is put into dilute hydrochloric acid, and the dilute hydrochloric acid comes from the pickling solution produced b...

Embodiment 2

[0077] The invention provides a method for recycling unfused zircon sand in the process of preparing zirconium oxychloride by an alkali fusion method. After the water washing and transformation section and before the acidification section, an unfused zircon sand recovery process is added, and the unmelted zircon sand is recovered. Zircon sand is precipitated and separated from the dilute hydrochloric acid solution transferred from water; the operation steps are as follows:

[0078] ①. Dilute hydrochloric acid dissolved water transfer material

[0079] In the dilute hydrochloric acid dissolving reactor, 1 ton of water is transferred to the material (the zirconium content is 40%, according to the alkali hydrolysis rate of 98%, it is converted into 0.628 tons of 65% zircon sand) according to the water transfer: dilute hydrochloric acid (mass ratio) = The ratio of 1:2.5 is put into dilute hydrochloric acid, and the dilute hydrochloric acid comes from the pickling solution produced...

Embodiment 3

[0090] The invention provides a method for recycling unfused zircon sand in the process of preparing zirconium oxychloride by an alkali fusion method. After the water washing and transformation section and before the acidification section, an unfused zircon sand recovery process is added, and the unmelted zircon sand is recovered. Zircon sand is precipitated and separated from the dilute hydrochloric acid solution transferred from water; the operation steps are as follows:

[0091] ①. Dilute hydrochloric acid dissolved water transfer material

[0092] In the dilute hydrochloric acid dissolving reactor, 1 ton of water is transferred to the material (the zirconium content is 40%, according to the alkali hydrolysis rate of 98%, it is converted into 0.628 tons of 65% zircon sand) according to the water transfer: dilute hydrochloric acid (mass ratio) = The ratio of 1:2.8 is put into dilute hydrochloric acid, and the dilute hydrochloric acid comes from the pickling solution produced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com