Hyperbranched ionic liquid based on HCCP and application of hyperbranched ionic liquid as fire retardant

A technology of hexachlorocyclotriphosphazene and ionic liquid, which is applied in the field of hyperbranched ionic liquid flame retardants, can solve problems such as no research reports on HCCP grafted ionic liquid, and achieves simple process, easy control, and low equipment requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

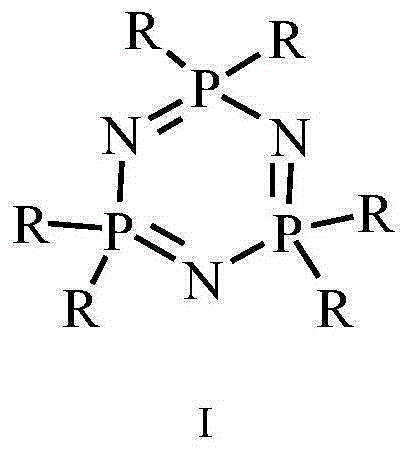

[0052] Dissolve 3.47 g of HCCP in 50 ml of acetonitrile, then add 9.93 g of N-butylimidazole (nBuMI) and 0.3 g of potassium iodide (KI), stir the reaction at 40°C for 2 hours, filter and dry the filter cake to obtain 10.09 g of N 3 P 3 (C 7 H 12 N 2 ) 6 Cl 6 , Abbreviated as HCCP-[nBuMI]Cl, the yield is 92.3%.

[0053] Dissolve 5 g of HCCP-[nBuMI]Cl in 20 ml of deionized water, and add 6.73 g of potassium hexafluorophosphate (KPF 6 ) And react at 20-30°C for 24 hours. After the reaction, the reactants are poured into 80 ml methanol to precipitate the product. The resulting mixture is suction filtered and the filter cake is vacuum dried to obtain 6.82 g of HCCP-based hyperbranched ionic liquid. N 3 P 3 (C 7 H 12 N 2 ) 6 (PF 6 ) 6 , Marked as HCCP-[nBuMI]PF 6, The yield was 85.2%.

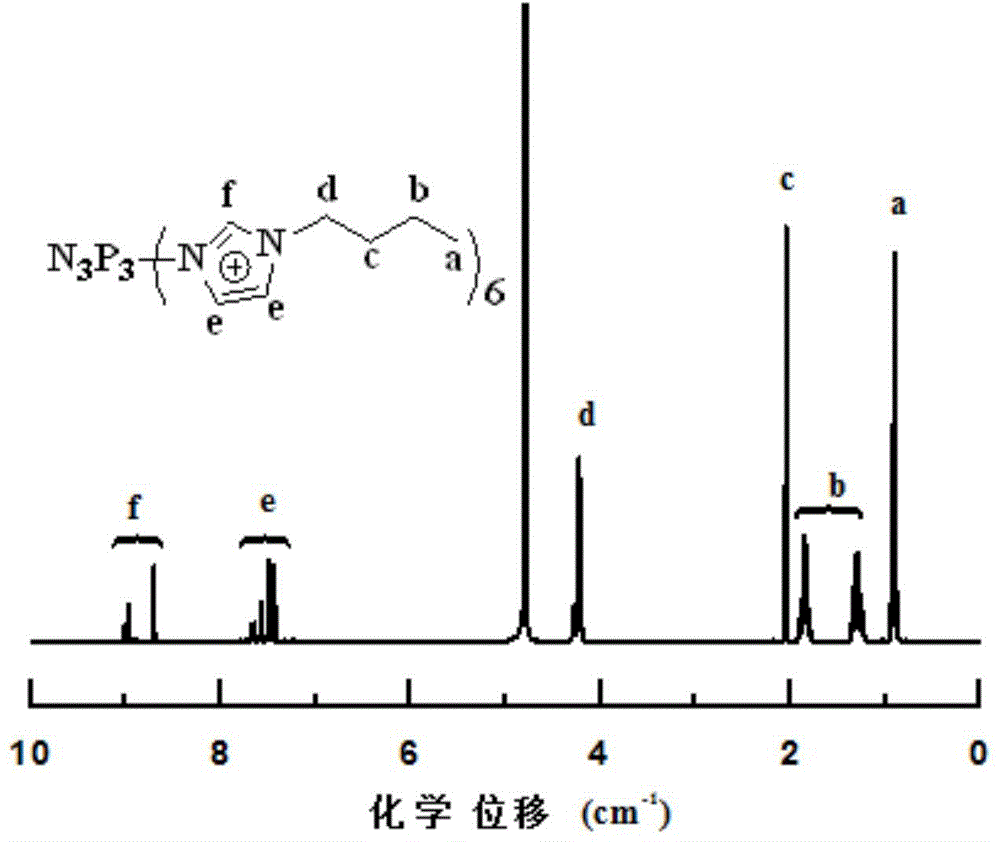

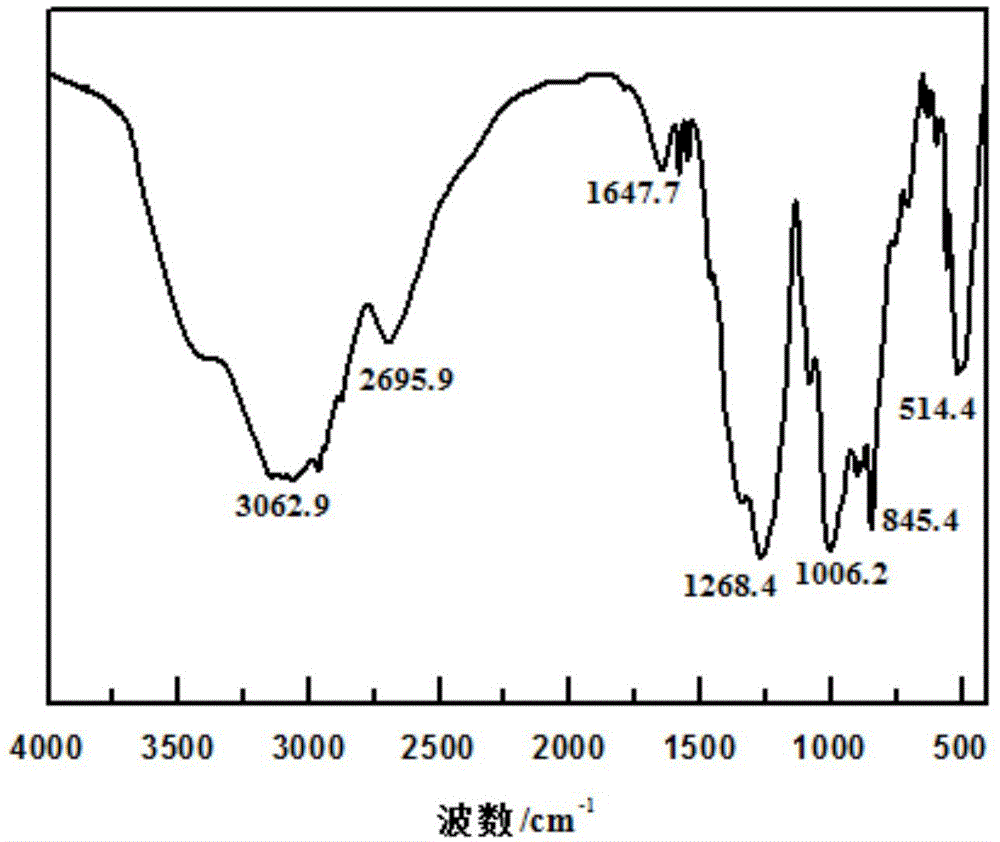

[0054] HCCP-[nBuMI]PF prepared 6 of 1 H NMR see attached figure 1 As shown, see the attached infrared spectrum figure 2 Shown.

[0055] Take 2.5 grams of HCCP-[nBuMI]PF 6 And 47.5 grams of GPPS were prep...

Embodiment 2

[0058] Dissolve 3.47 g of HCCP in 50 ml of acetonitrile, then add 6.57 g of N-methylimidazole (nMeMI) and 0.2 g of sodium iodide (NaI), stir the reaction at 40°C for 2 hours, filter and dry the filter cake to obtain 7.99 g of N 3 P 3 (C 4 H 6 N 2 ) 6 Cl 6 , Abbreviated as HCCP-[nMeMI]Cl, the yield is 95.1%.

[0059] Dissolve 5 grams of HCCP-[nMeMI]Cl in 20ml of deionized water, then add 6.73 grams of potassium hexafluorophosphate (KPF 6 ) And react at 20-30°C for 24 hours. After the reaction, the reactants are poured into 80 ml methanol to precipitate the product. The resulting mixture is suction filtered and the filter cake is vacuum dried to obtain 7.55 g of HCCP-based hyperbranched ionic liquid. N 3 P 3 (C 4 H 6 N 2 ) 6 (PF 6 ) 6 , Marked as HCCP-[nMeMI]PF 6, The yield was 84.7%.

[0060] Take 2.5 grams of HCCP-[nMeMI]PF 6 And 47.5 grams of GPPS were prepared with a micro extruder and a micro injection machine at 200°C, and the limiting oxygen index was tested to be 27.9%.

[0061...

Embodiment 3

[0063] Dissolve 3.47 g of HCCP in 50 ml of acetonitrile, then add 8.10 g of triethylamine (TEA) and 0.3 g of potassium iodide (KI), stir the reaction at 40°C for 2 hours, filter and dry the filter cake to obtain 8.52 g of N 3 P 3 (C 6 H 15 N) 6 Cl 6 , Abbreviated as HCCP-[TEA]Cl, the yield is 89.2%.

[0064] Take 6 grams of HCCP-[TEA]Cl dissolved in 20ml of deionized water, and then add 10.82 grams of lithium bis(trifluoromethanesulfonyl)imide (LiNTF 2 ) And react at 20~30℃ for 24 hours. After the reaction, the reactants are poured into 80 ml of ethanol to precipitate the product. The resulting mixture is suction filtered and the filter cake is vacuum dried to obtain 5.8 g of HCCP-based hyperbranched ionic liquid. N 3 P 3 (C 6 H 15 N) 6 (N(SO 2 CF 3 ) 2 ) 6 , Abbreviated as HCCP-[TEA][NTF 2 ], the yield is 51.2%.

[0065] Take 2.5 grams of HCCP-[TEA][NTF 2 ] And 47.5 grams of GPPS were prepared with a micro extruder and a micro injection machine at 200°C, and the limiting oxygen ind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com