Method for extracting human serum albumin from plasma and increasing yield

A technology for human albumin and plasma, which is applied in the field of extracting human albumin to improve the yield, and achieves the effects of smooth and concise production process, reduction of one-step losses, and huge economic and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

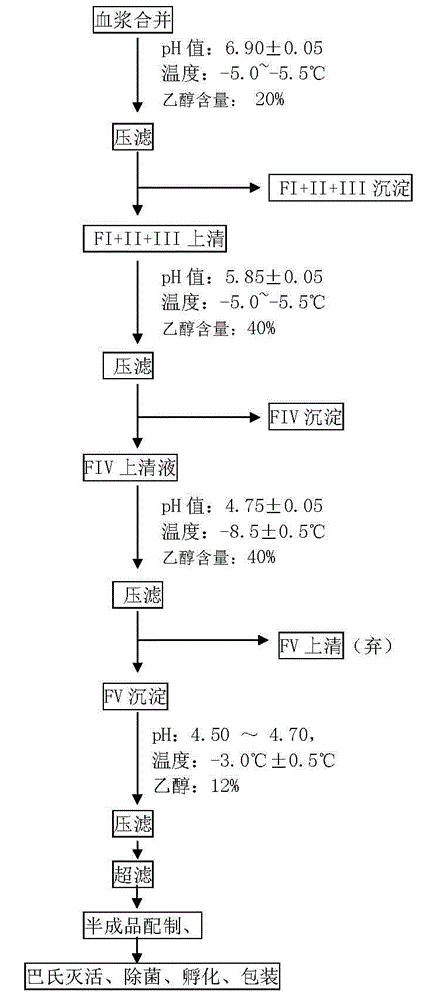

[0030] The present invention in concrete implementation, comprises the following steps:

[0031] (1) Merging and melting of plasma: After breaking the bag, put it into a clean melting tank, open the melting tank, stir and melt the temperature controller, and make the plasma in the melting tank melt when the water temperature is less than 35°C. Keep it at 2℃~3℃;

[0032](2) Preparation of components I+II+III and pressure filtration separation: measure the volume of the combined plasma, adjust the pH of the mixed plasma to 6.85-6.95 with pH 4.0 acetate buffer, turn on the circulating cooling system to cool down the plasma, wait for the plasma to After cooling down to 0°C, add 95% ethanol (v / v) at -16°C; add ethanol at a rate of 55L / h, so that the final ethanol concentration of the product reaches 20% by volume (v / v). During the process of adding ethanol, the temperature Never higher than 0°C, the final plasma temperature is controlled at -5.2~-5.3°C, continue to stir for 2.5 ho...

Embodiment 2

[0046] The present invention can also be realized by the following steps in implementation:

[0047] (1) Merging and melting of plasma: After breaking the bag, put it into a clean melting tank, open the melting tank, stir and melt the temperature controller, and make the plasma in the melting tank melt when the water temperature is less than 35°C. Keep it at 0℃~4℃;

[0048] (2) Production of components I+II+III and pressure filtration separation: Measure the volume of the combined plasma, adjust the pH of the mixed plasma to 6.85 with pH 4.0 acetate buffer, turn on the circulating cooling system to cool the plasma, wait until the plasma is cooled to After 0°C, add ethanol with a mass concentration of 95% below -15°C; add ethanol at a rate of ≤60L / h, so that the final ethanol concentration of the product reaches a volume ratio of 20% (v / v). During the process of adding ethanol, the temperature remains constant It should not be higher than 0°C, and the final plasma temperature ...

Embodiment 3

[0062] In specific implementation, the present invention can also be realized by the following steps:

[0063] (1) Merging and melting of plasma: After breaking the bag, put it into a clean melting tank, open the melting tank, stir and melt the temperature controller, and make the plasma in the melting tank melt when the water temperature is less than 35°C. Keep it at 2~3℃;

[0064] (2) Production of components I+II+III and pressure filtration separation: measure the volume of the combined plasma, adjust the pH of the mixed plasma to 6.9 with pH 4.0 acetate buffer, turn on the circulating cooling system to cool the plasma, and wait until the plasma is cooled to After 0°C, add ethanol with a mass concentration of 95% at -17°C; add ethanol at a rate of 60L / h, so that the final ethanol concentration of the product reaches a volume ratio of 20% (v / v). During the process of adding ethanol, the temperature should not be higher than 0°C, the final plasma temperature is controlled at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com