Polypropylene resin for biaxially oriented film and preparation method of polypropylene resin

A technology of biaxially stretched film and polypropylene resin, applied in the field of polypropylene resin for biaxially stretched film and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Preparation of Spherical Catalyst Components

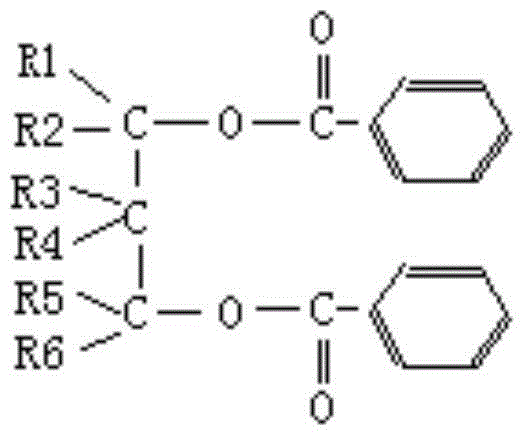

[0065] Add 90ml of titanium tetrachloride and 10ml of hexane into a 300ml stirred glass reaction bottle fully replaced by high-purity nitrogen, cool to -20°C, add 8g of spherical magnesium chloride alcoholate carrier (for the preparation method, refer to the Chinese patent CN1330086A), under stirring, slowly raise the temperature to 110°C in stages, add 1.3ml of 2,4-pentanediol dibenzoate and 1.3ml of 2-isopropyl-2-isoamyl during the heating process - 1,3-dimethoxypropane, after keeping the temperature at 110°C for 0.5h, filter off the liquid, add titanium tetrachloride to treat twice, each time the amount of titanium tetrachloride is 80ml, and then wash five times with hexane, Spherical catalysts were obtained after vacuum drying.

[0066] Propylene polymerization

[0067] In a 5L autoclave, a nitrogen stream was used for purging, and then a hexane solution containing 0.5 mmol of triethylaluminum, a hexane solution conta...

Embodiment 2

[0069] The preparation of the spherical catalyst component is the same as in Example 1.

[0070] Propylene polymerization: the same as in Example 1 except that the precontact reaction is 2 mins and the temperature is 25°C.

Embodiment 3

[0072] The preparation of the spherical catalyst component is the same as in Example 1.

[0073] Propylene polymerization: the same as in Example 1 except that the precontact reaction is 10 minutes and the temperature is 15°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com