Method for Polymerization of Acrylamide Using Ultrasonic Technology

A technology of acrylamide and ultrasonic technology, which is applied in the field of preparation of instant ultra-high intrinsic viscosity anionic polyacrylamide dry powder, can solve the problems of no chemical action involved, no obvious contribution to the shortening of polymerization time, etc., and achieve simple polymerization process Practical, easy for large-scale industrial production, and the effect of activity enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

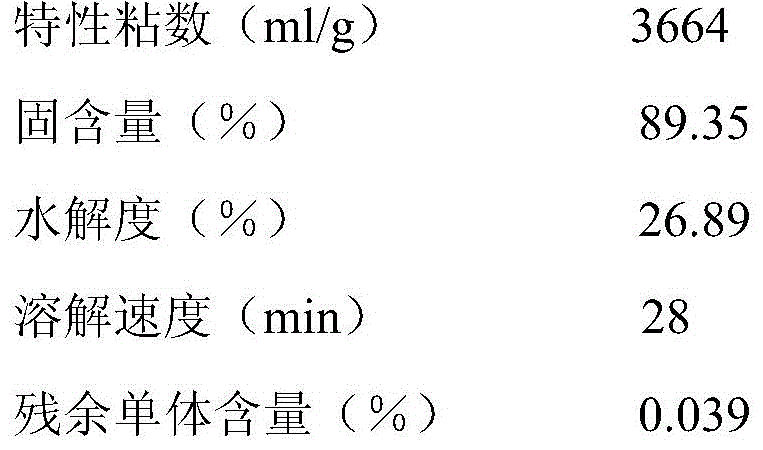

Embodiment 1

[0036]Add 133.3g of deionized water into the polymerization container, add 666.7g of 30% acrylamide monomer aqueous solution, 36g of sodium carbonate, 6g of urea, and 0.1g of sodium formate in turn under stirring, and adjust the system with NaOH after all the solids in the system are dissolved The pH value of the polymerizer is 11.5. Put the polymerizer in a 20°C constant temperature water bath with an ultrasonic device, and feed nitrogen into the polymerization system. The nitrogen flow rate is 4L / min. At the same time, the ultrasonic wave is turned on. After 15 minutes, add 0.05 g of initiator azobisisobutylamidine hydrochloride after ultrasonic intensity of 50 W and ultrasonic for 5 minutes. After about 2.5 minutes, the polymerization system starts to polymerize and become sticky, and the temperature rises. After 2.5 hours, the temperature of the polymerization system reaches 69.7 ° C, and then The temperature of the system begins to drop, the polymerization reaction ends, a...

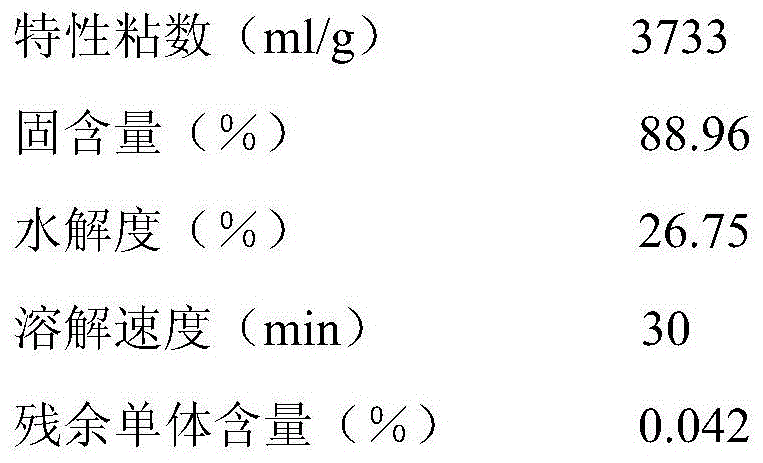

Embodiment 2

[0044] According to the method and steps of Example 1, the difference is that the ultrasonic intensity of the monomer and initiator in Example 2 is 100W, and other conditions are the same, and the technical indicators of the polyacrylamide dry powder obtained are as follows:

[0045]

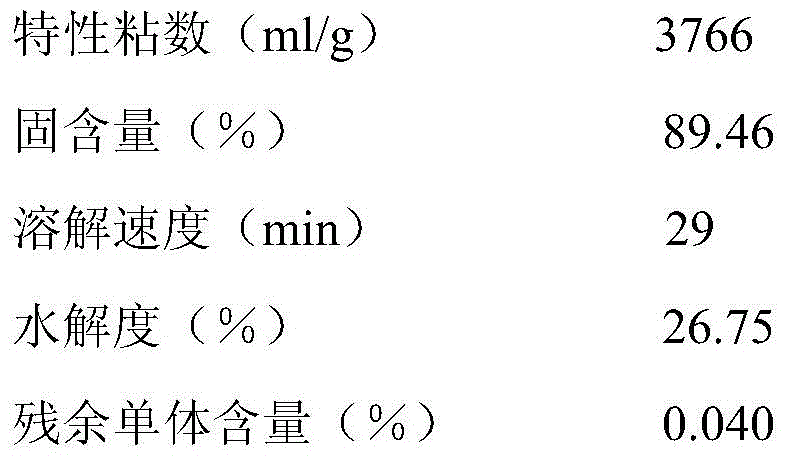

Embodiment 3

[0047] According to the method and steps of Example 1, the difference is that the ultrasonic intensity of the monomer and initiator in Example 3 is 150W, and other conditions are the same, and the technical indicators of the polyacrylamide dry powder obtained are as follows:

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com