Preparation method of high-molecular copolymer cationic polyacrylamide flocculant

A polyacrylamide and cationic technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of poor treatment effect of anion wastewater, and achieve the effect of high viscosity-average molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

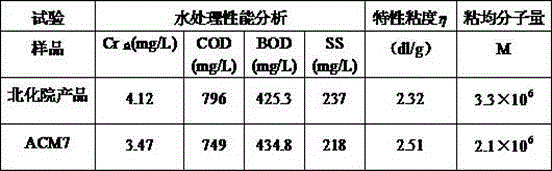

[0032] In a factory in Jiangyin, this product ACM6 was used to conduct a comparative experiment with British products. Now take 0.5g of ACM6 and British products and dissolve them in 500ml of hot water and stir evenly. In mud, mix evenly, filter and extrude into a block without sticking, and the filtrate has been tested for COD, BOD, Cr 总 , SS and other tests, from the results, all the data are superior to foreign products, the comparative data are as follows:

[0033]

Embodiment 2

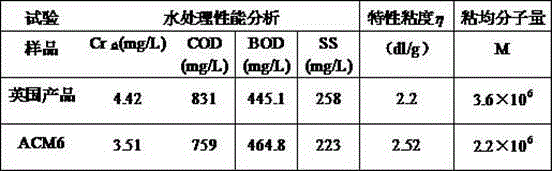

[0035] A factory in Jiangyin used this product ACM7 and the product of Beijing Research Institute of Chemical Industry to conduct a comparative experiment. Now take 0.5g of ACM7 and the British product and dissolve them in 500ml of hot water and stir evenly. Take 2ml and add them to 250ml of anionic flocculant for treatment In the mixed sludge, mix evenly, filter and extrude into a block without sticking, and the filtrate has undergone COD, BOD, Cr 总 , SS and other tests, from the results, all the data are superior to foreign products, the comparative data are as follows:

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com