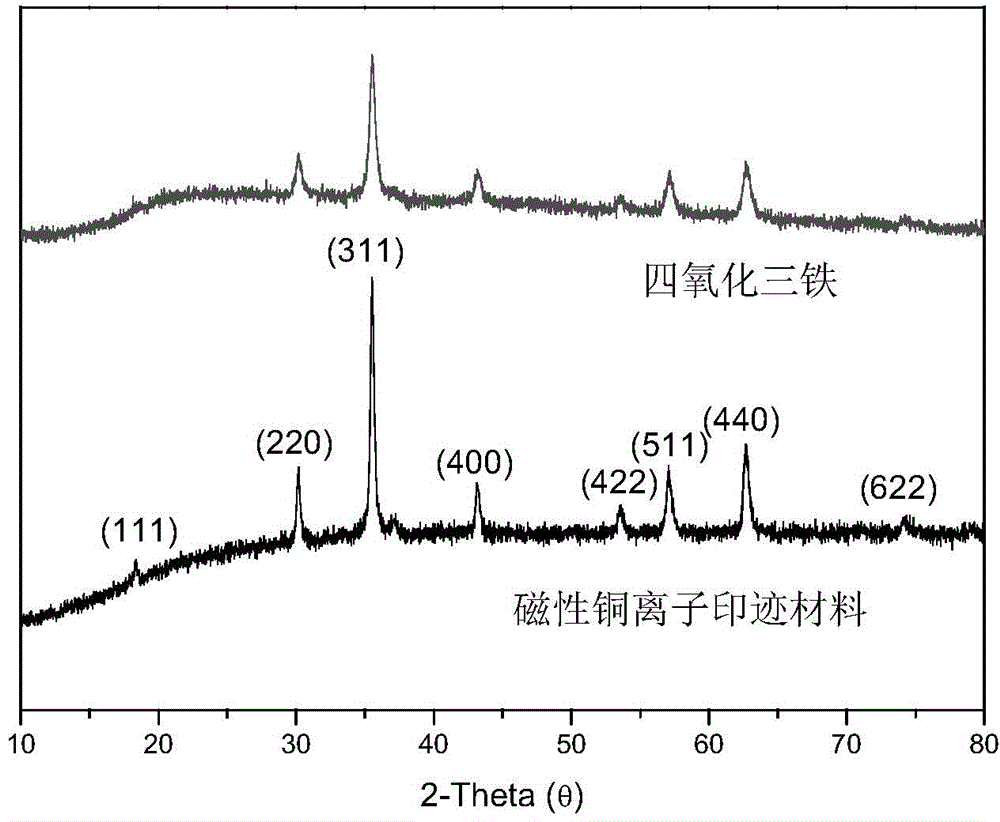

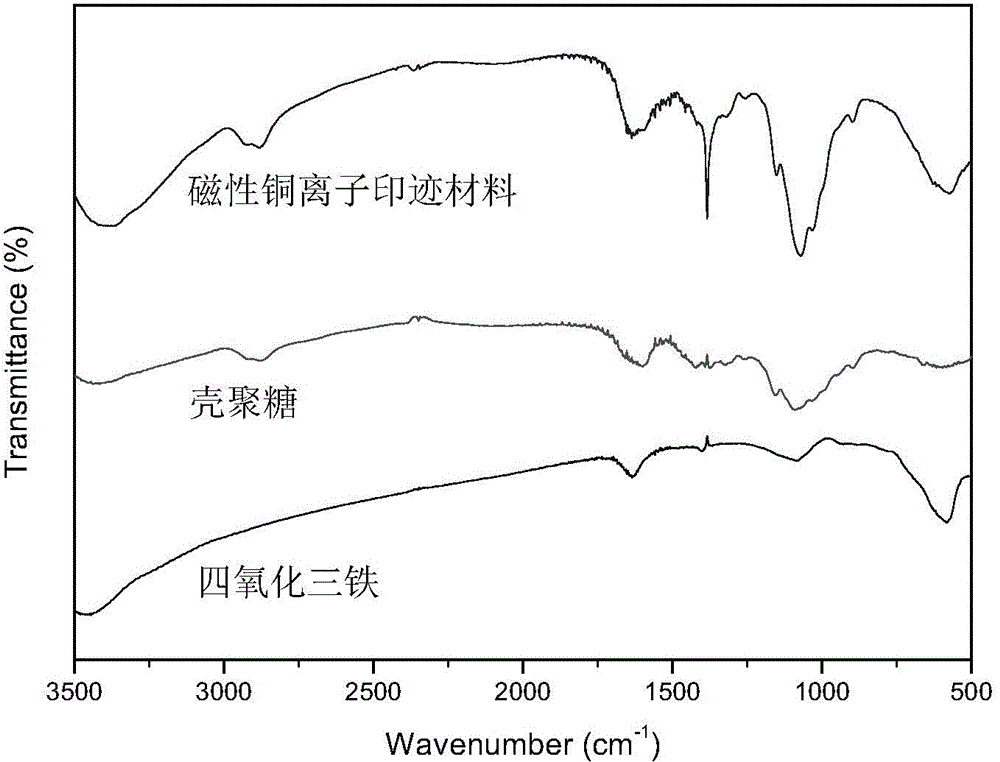

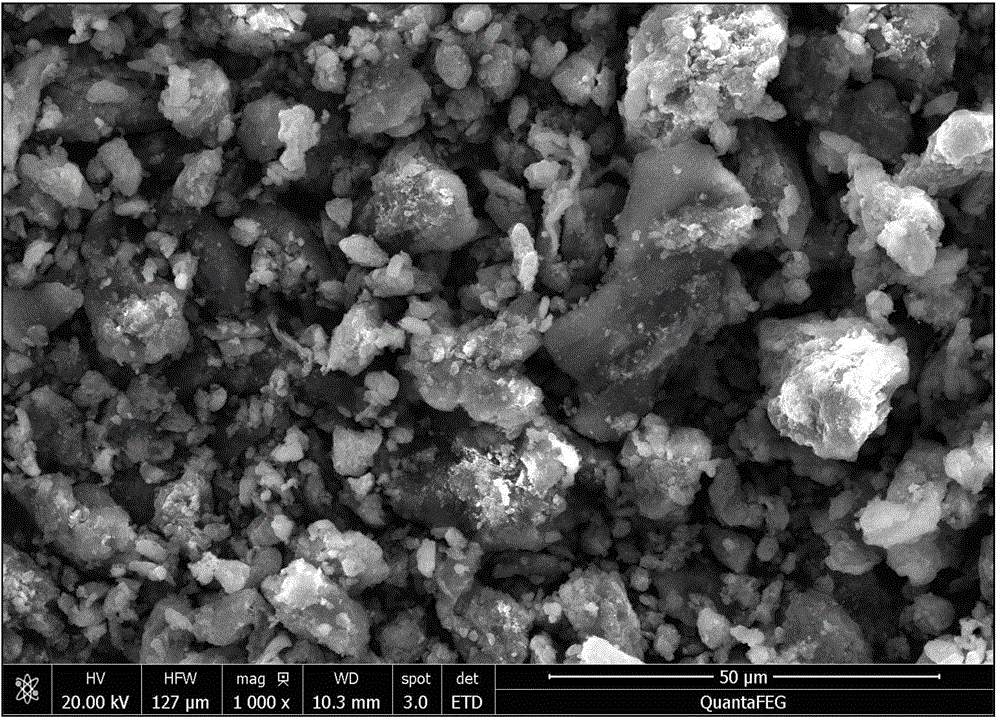

Method for preparing magnetic copper ion imprinting material from steel pickling waste liquid and application of method

A technology for iron and steel pickling waste liquid and imprinted materials, which is applied in the fields of inorganic material magnetism, chemical instruments and methods, and other chemical processes, can solve problems such as waste of resources, and achieves low preparation cost, huge environmental and economic benefits, and good The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The method for preparing magnetic copper ion imprinting material by using iron and steel pickling waste liquid includes the following steps:

[0063] (1) Weigh 2.0 g of chitosan powder and dissolve it in 200 mL of 3.5% acetic acid solution to form a chitosan-acetic acid solution;

[0064] (2) Add 5 mL of iron and steel pickling waste to the upper system, stir to make the solution fully mixed; where the total iron content in the iron and steel pickling waste is 100 g / L;

[0065] (3) Add 30 mL of 5 mol / L ammonia water dropwise to the upper step system until the pH of the reaction system reaches 10, and continue to heat and stir for 3.5 h at 65°C;

[0066] (4) After the reaction, the black precipitate produced in the system is separated by a magnetic separation method, and washed to neutrality to obtain the initial magnetic chitosan mixture;

[0067] (5) Put the initial magnetic chitosan mixture obtained in the previous step in a 150 mg / L copper sulfate solution and fully react, add...

Embodiment 2

[0075] Example 2: The optimal choice of the amount of crosslinking agent

[0076] The preparation method of magnetic copper ion imprinting material with different amounts of glutaraldehyde includes the following steps:

[0077] (1) Weigh 2.0 g of chitosan powder and dissolve it in 200 mL of 3.5% acetic acid solution to form a chitosan-acetic acid solution;

[0078] (2) Add 5 mL of iron and steel pickling waste to the upper system, stir to make the solution fully mixed; where the total iron content in the iron and steel pickling waste is 100 g / L;

[0079] (3) Add 30 mL of 5 mol / L ammonia water dropwise to the upper step system until the pH of the reaction system reaches 10, and continue to heat and stir for 3.5 h at 65°C;

[0080] (4) After the reaction, the black precipitate produced in the system is separated by magnetic separation method, and washed with deionized water to neutrality to obtain the initial magnetic chitosan mixture;

[0081] (5) Put the initial magnetic chitosan mixtur...

Embodiment 3

[0088] The method for preparing magnetic copper ion imprinting material by using iron and steel pickling waste liquid includes the following steps:

[0089] 1) Weigh 2.0 g of chitosan powder and dissolve it in 200 mL of 2% hydrochloric acid solution to form a chitosan-acetic acid solution;

[0090] 2) Add 5 mL of iron and steel pickling waste to the previous system, stir to make the solution fully mixed; among them, the total iron content in the iron and steel pickling waste is 200 g / L;

[0091] 3) Add 5 mol / L ammonia water dropwise to the upper step system until the pH of the reaction system reaches 11, and continue to heat and stir for 2 h at 70°C;

[0092] 4) After the reaction, the black precipitate produced in the system is separated by magnetic separation method, and washed with deionized water to neutrality to obtain the initial magnetic chitosan mixture;

[0093] 5) Put the initial magnetic chitosan mixture obtained in the previous step in a 200 mg / L copper sulfate solution and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com