High-toughness high-Tg-value epoxy resin and preparation method

A technology of epoxy resin and group epoxy resin, which is applied in the field of epoxy resin and its preparation, can solve the problems of application limitation, decline of impact resistance of resin matrix, etc., and achieve the effect of improving poor toughness and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028]Embodiment 1 Preparation of high toughness and high Tg epoxy resin

[0029] The preparation method of the high toughness high Tg epoxy resin of the present embodiment may further comprise the steps:

[0030] 1) Preparation of toughening agent paste, epoxy resin in toughening agent paste system B, toughening agent respectively choose trifunctional epoxy resin AFG-90, nano core shell particle toughening agent "Kane Ace" MX125, according to weight The ratio is 15:10 combination. First weigh 45g of trifunctional epoxy resin AFG-90 into the beaker, then weigh 30g of nano core-shell particle toughening agent "Kane Ace" MX125 into the beaker, mechanically stir the two to mix evenly, and finally pass through the three-roller grinding equipment Mix more fully to obtain a uniformly mixed toughener paste for later use.

[0031] 2) Preparation of high-toughness, high-Tg epoxy resin composition. Resin mixture A selects trifunctional epoxy resin AFG-90 and cresol-formaldehyde epoxy ...

Embodiment 2~6

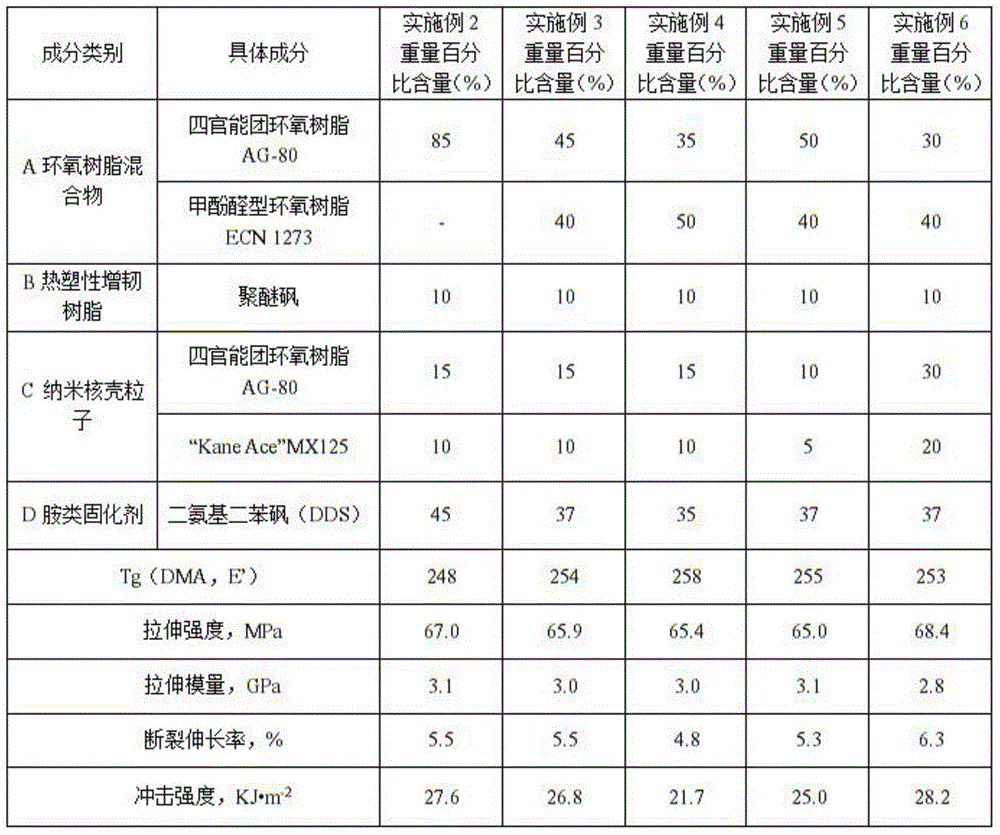

[0036] The preparation method of the epoxy resin cast body is as shown in Example 1, and the contained specific components are shown in Table 2 below:

[0037] Table 2 Components and properties of cast resin

[0038]

[0039] As shown in the results in Table 2, when different ratios of four-functional epoxy resin AG-80 and nano-core-shell particle toughening agent "Kane Ace" MX125 are used according to the embodiments disclosed herein, curable Composition: High glass transition temperature, high impact strength, high tensile strength, high stretch film weight and high elongation at break.

Embodiment 7~10

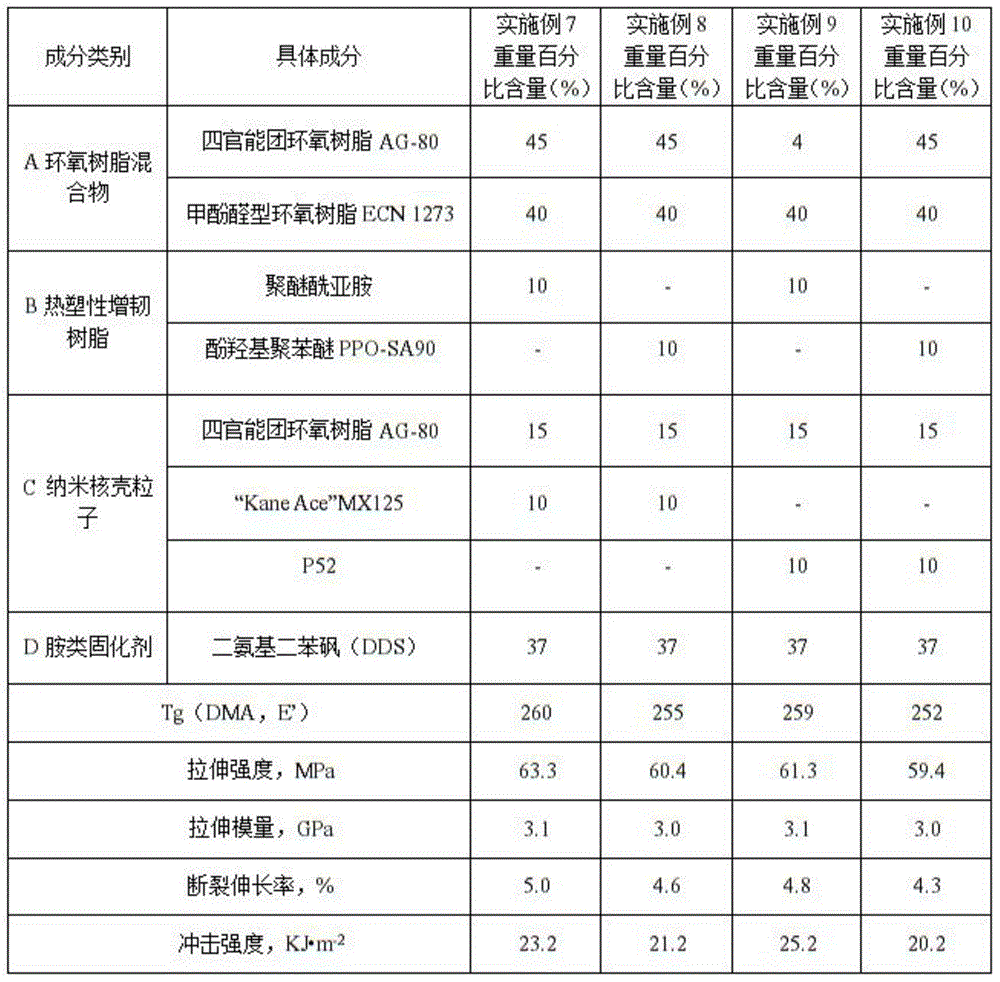

[0041] The preparation method of epoxy resin is as shown in Example 1, and the contained specific components are shown in Table 3 below

[0042] Table 3 Resin mixture components and their casting properties

[0043]

[0044] As shown in the results in Table 3, when using different types of thermoplastic tougheners such as polyetherimide, phenolic hydroxyl polyphenylene ether PPO-SA90 and nano core-shell particle tougheners such as "Kane Ace" according to the embodiments disclosed herein MX217, P52, can form a curable composition with the following properties: high glass transition temperature, high impact strength, high tensile strength, high tensile modulus and high elongation at break.

[0045] In summary, the curable epoxy resin disclosed herein can include multifunctional epoxy resin, thermoplastic toughening agent, nano core-shell particle toughening agent and amine curing agent, and such composition can exhibit multiple A good balance of various physical properties i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com