An early-strength emulsion for cold regeneration of waste asphalt pavement, its preparation method and its application

A technology for waste asphalt and asphalt pavement, which is applied in solid waste management, sustainable waste treatment, building components, etc. It can solve the problem of low early strength of cold regeneration, achieve improved water damage resistance, excellent performance, and expand the scope of application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

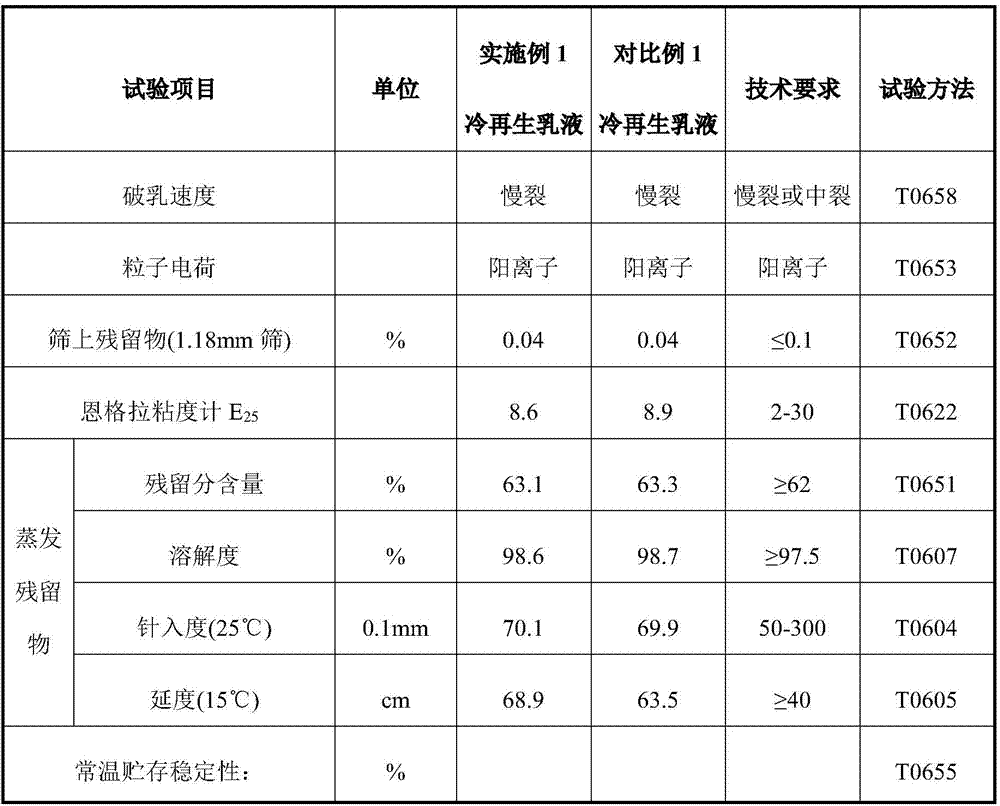

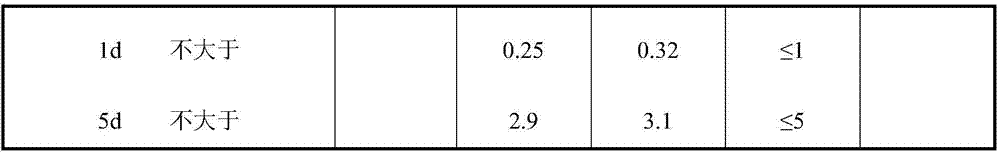

Embodiment 1

[0037] Weigh 4.0 parts of emulsifier, add 0.15 parts of stabilizer, 0.1 parts of activator, and 0.2 parts of dispersant, then add water to 36 parts, add pH adjustment aids to pH = 2.0, and finally add water to 38 parts to obtain soap liquid. Weigh 62 parts of petroleum pitch.

[0038] Described asphalt is No. 70 road petroleum asphalt (Korean SK company), and described cold regeneration emulsifier is IndulinW-5 slow-cracking type emulsifier (U.S. Meadwestvaco company); Described stabilizer is calcium chloride; The activator is triethanolamine (Jiaxing Jinyan Chemical Co., Ltd.); the dispersant is PCA-I type superplasticizer (Jiangsu Subote New Material Co., Ltd.), and the pH adjustment assistant is hydrochloric acid .

[0039] The preparation method of above-mentioned early strength type cold regeneration emulsion is as follows:

[0040] Take the above 62 parts of petroleum asphalt and heat to 135°C, heat the above 38 parts of soap liquid to 55°C, transport the soap liquid m...

Embodiment 2

[0056] Weigh 2.5 parts of emulsifier, add 0.2 parts of stabilizer, 2 parts of activator, and 0.5 parts of dispersant, then add water to 36 parts, add pH adjustment aids to pH=2.5, and finally add water to 38 parts to obtain soap. Weigh 55 parts of petroleum pitch.

[0057] Described asphalt is No. 90 road petroleum asphalt (North Asphalt Co., Ltd., Panjin City, Liaoning), and described cold regeneration emulsifier is E4875 slow-cracking type emulsifier (Akzo Nobel Company); Described stabilizer is chlorinated Calcium; The activator is diethanolamine (Nanjing Gutian Chemical Co., Ltd.); The dispersant is PCA-100P powder polycarboxylate water reducer (Jiangsu Subote New Material Co., Ltd.); The pH The value adjustment aid is hydrochloric acid.

[0058] The preparation method of above-mentioned early strength type cold regeneration emulsion is as follows:

[0059] Take the above 55 parts of petroleum asphalt and heat to 135°C, heat the above 38 parts of soap liquid to 60°C, tra...

Embodiment 3

[0075] Weigh 4 parts of emulsifier, add 5 parts of modifier, 1 part of stabilizer, 0.3 part of activator, 0.3 part of dispersant, then add water to 35 parts, add pH adjustment assistant to pH = 2.2, and finally add water to 37 parts , to obtain soap solution. Weigh 63 parts of petroleum pitch.

[0076] Described asphalt is No. 70 road petroleum asphalts (Hubei Guochuang High-tech Materials Co., Ltd.), and described cold regeneration emulsifier is Slow-cracking emulsifier (Jiangsu Subote New Material Co., Ltd.); the modifier is Indulin1468 styrene-butadiene latex (Meadwestvaco, U.S.), and the stabilizer is calcium chloride; the activator is three Isopropanolamine (Taizhou Greenland Chemical Co., Ltd.); the dispersant is a calcium naphthalenesulfonate superplasticizer (Jiangsu Subote New Material Co., Ltd); the pH adjustment assistant is hydrochloric acid.

[0077] The preparation method of above-mentioned early strength type cold regeneration emulsion is as follows:

[0078...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stability | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com