Woodware surface protecting coating composition and preparation method thereof

A protective coating and composition technology, applied in the field of wood surface protective coating composition and its preparation, can solve problems such as easy to be scraped off, easy to produce cracks, coating pinholes, etc., to prevent the diffusion of moisture and other substances, and prevent wood Deformation, the effect of controlling moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

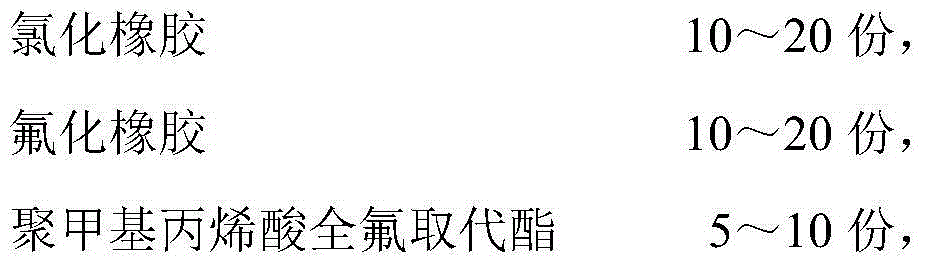

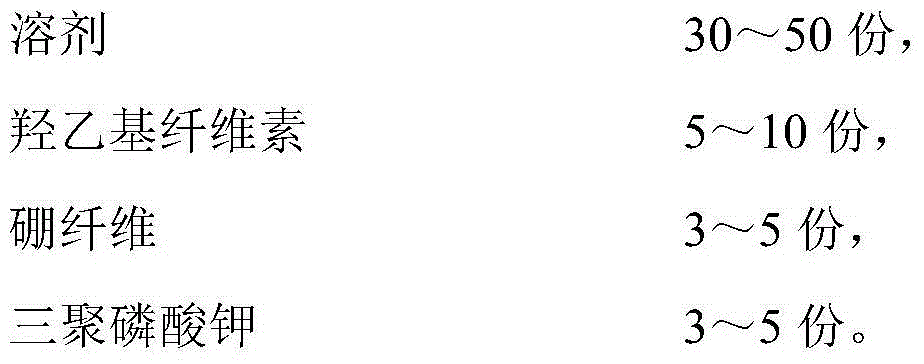

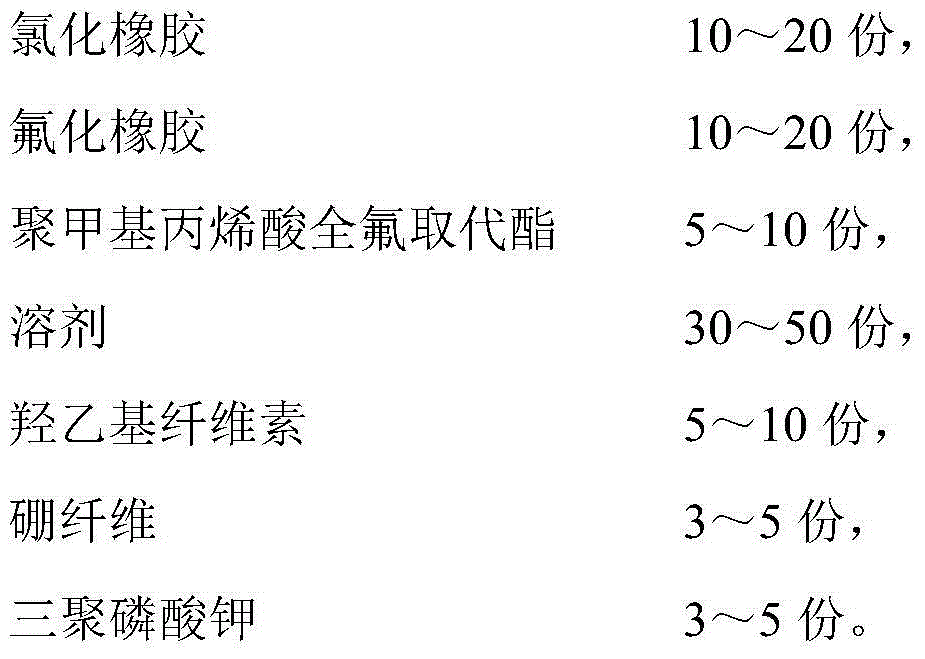

Method used

Image

Examples

Embodiment 1

[0028] The present embodiment relates to a kind of protective paint for wooden floor, and its preparation method comprises the following processing steps:

[0029] (1) Put all the solvents, that is, 30 parts of butanone and 10 parts of dimethyl sulfoxide into the reaction kettle, and heat to about 45°C for stirring;

[0030] (2) Keep stirring and put 5 parts of polytrifluoroethyl methacrylate, 5 parts of hydroxyethyl cellulose, 5 parts of boron fiber, and 3 parts of potassium tripolyphosphate into the reaction kettle in turn, and stir for about 1 hour;

[0031] (3) After mixing evenly, slowly put 10 parts of chlorinated rubber and 20 parts of perfluoroether rubber into the reaction kettle;

[0032] (4) When all the solids are dissolved and mixed evenly, shut down and mature for more than 12 hours;

[0033] (5) Measure the solid content and adjust to the theoretical value; the protective coating is obtained.

Embodiment 2

[0035] This embodiment relates to a kind of protective coating for wooden ornaments, and its preparation method comprises the following process steps:

[0036] (1) Put all the solvents, that is, 30 parts of N,N-dimethylformamide and 20 parts of N,N-dimethylacetamide into the reaction kettle, and heat to about 45°C for stirring;

[0037] (2) Keep stirring and put 10 parts of polyhexafluorobutyl methacrylate-dodecafluoroheptyl methacrylate, 10 parts of hydroxyethyl cellulose, 3 parts of boron fiber, and 5 parts of potassium tripolyphosphate into the reaction kettle in turn medium, stir for about 1 hour;

[0038] (3) After mixing evenly, slowly put 20 parts of chlorinated rubber and 10 parts of tetrapropylene fluororubber into the reaction kettle;

[0039] (4) When all the solids are dissolved and mixed evenly, shut down and mature for more than 12 hours;

[0040] (5) Measure the solid content and adjust to the theoretical value; the protective coating is obtained.

Embodiment 3

[0042] The present embodiment relates to a kind of protective paint for woodware, and its preparation method comprises the following processing steps:

[0043] (1) Put all the solvent, that is, 30 parts of triethyl phosphate into the reaction kettle, and heat it to about 45°C for stirring;

[0044] (2) Keep stirring and put 7 parts of dodecafluoroheptyl methacrylate, 6 parts of hydroxyethyl cellulose, 4 parts of boron fiber, and 4 parts of potassium tripolyphosphate into the reaction kettle in turn, and stir for about 1 hour;

[0045] (3) After being mixed evenly, 15 parts of chlorinated rubber and 15 parts of polyolefin fluororubber are slowly put into the reaction kettle;

[0046] (4) When all the solids are dissolved and mixed evenly, shut down and mature for more than 12 hours;

[0047] (5) Measure the solid content and adjust to the theoretical value; the protective coating is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com