Slippery water for shale gas fracturing and preparation method thereof

A technology of slick water and air pressure, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of a large number of organic solvents, complex technology, high production cost, etc., and achieve good friction reduction effect, good compatibility and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

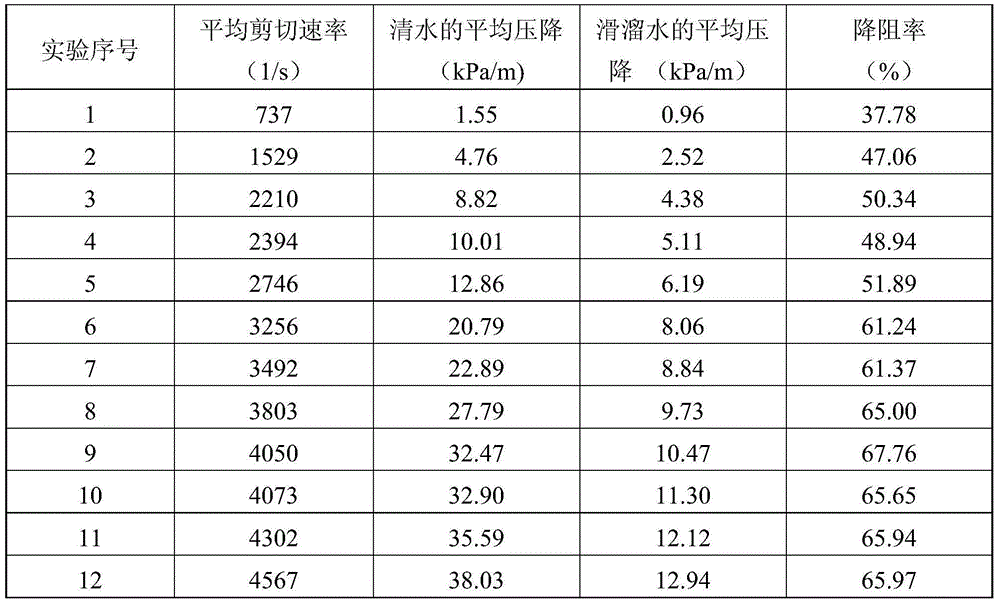

Examples

Embodiment Construction

[0020] 1. Composition of slick water formula: emulsion drag reducer 0.15%, clay stabilizer 0.3%, drainage aid 0.3%, potassium chloride 1.0%, fungicide 0.05%. The drag reducing agent is an emulsion-type drag reducing agent synthesized by an inverse emulsion polymerization process, which is a copolymer of acrylamide, 2-acrylamidodimethylpropanesulfonic acid, glycidyl methacrylate and acrylic acid, and is an anionic Type polyacrylamide, its viscosity-average molecular mass is 8.5 million, and its intrinsic viscosity is 1810mL·g -1 The clay stabilizer is a quaternary ammonium salt type cationic copolymer synthesized by epichlorohydrin, dimethylamine and ethylenediamine; the drainage aid is an aqueous solution of anionic fluorocarbon surfactant and methanol; the The fungicide is formaldehyde.

[0021] 2. Preparation of slippery water:

[0022] According to the above composition, weigh the required clear water, accurately weigh and record the types and amounts of each additive;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

| resistance reduction rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com