Tinpot heavy oil combination processing method

A combined processing and low-quality heavy oil technology, which is applied in the petroleum industry, hydrotreating process, hydrocarbon oil treatment, etc., can solve the problems of poor utilization of deoiled asphalt, difficult outlet of high-sulfur petroleum coke, and high coke, so as to achieve easy recovery of sulfur , reduce the emission of SOX, and increase the yield of light oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

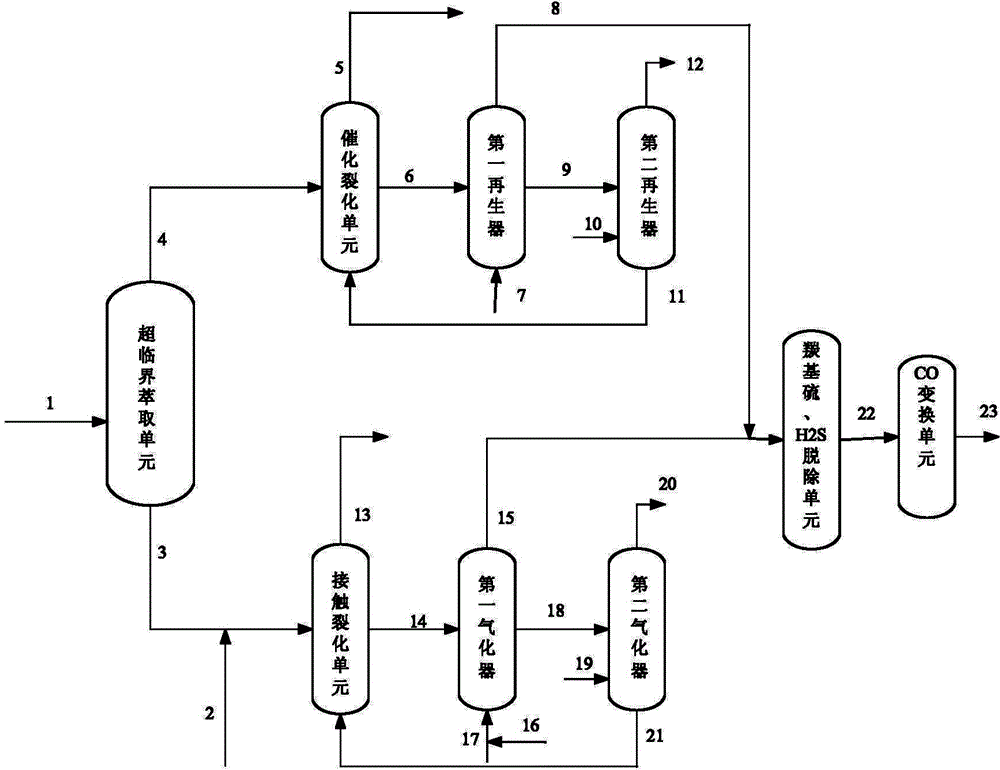

Method used

Image

Examples

Embodiment 1

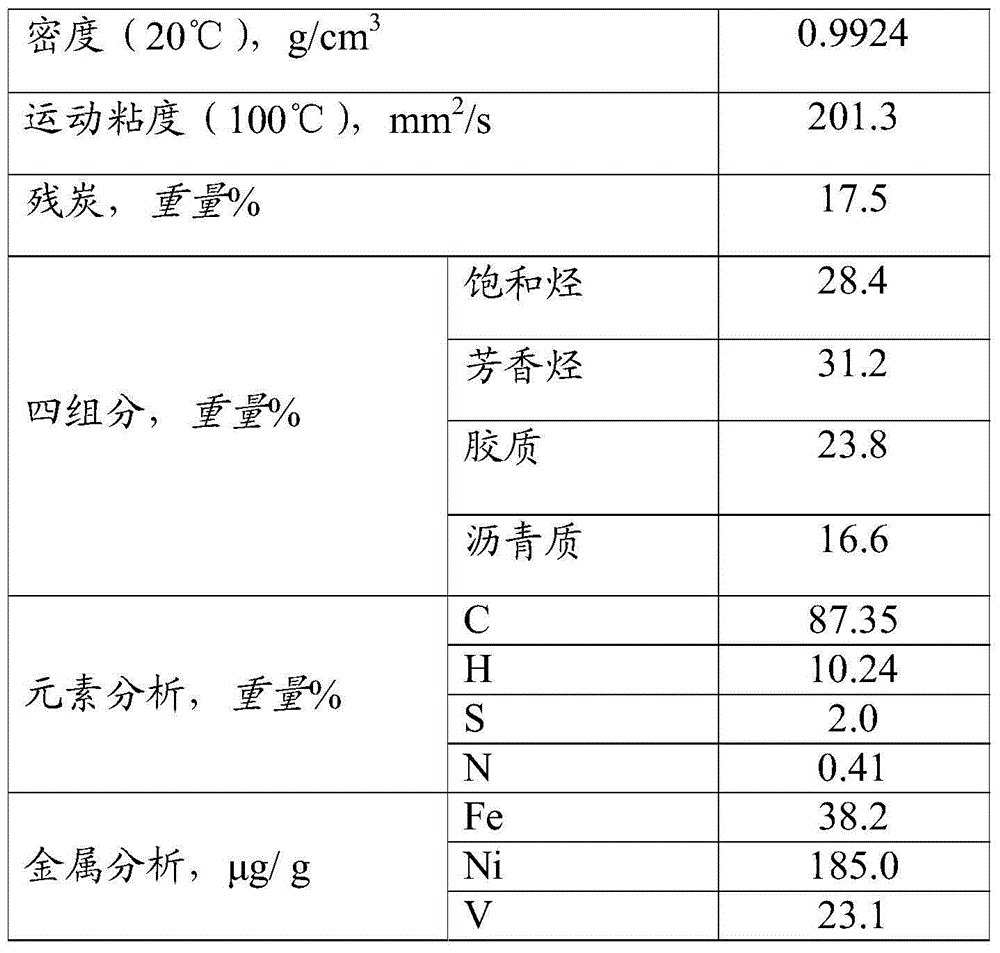

[0056] The vacuum residue is physically separated in a supercritical fluid extraction unit. The temperature at the top of the extraction tower is 240°C and the bottom of the tower is 220°C. The solvent is mixed pentane (w (n-pentane): w (isopentane)=1 : 2), the pressure range is 4 ~ 12MPa. Obtain yield after extraction is 40% of the extracted oil and 60% of the raffinated oil. The mass percentage of saturated and aromatic components in the extracted oil was 82.1%, the mass percentage of asphaltene was <0.1%, the residual carbon was 6.1%, and the content of metal (Ni+V) was 14.1 μg / g.

[0057] The extracted oil enters the catalytic cracking unit, and the process conditions are: reaction temperature 520°C, agent-to-oil ratio 7, water-to-oil ratio 0.05, reaction time 3s, and the distribution of the obtained products is shown in Table 2. The spent agent obtained after the catalytic cracking reaction enters the first regenerator for oxygen-poor regeneration. The process conditions...

Embodiment 2

[0061] The vacuum residue is physically separated in a supercritical fluid extraction unit, the temperature at the top of the extraction tower is 230°C, the bottom of the tower is 210°C, and the solvent is mixed pentane (w (n-pentane):w (isopentane)=1 : 1), the pressure range is 4 ~ 12MPa. Obtain yield after extraction is 38% extract oil and 62% raffinate oil. The mass percentage of saturated and aromatic components in the extracted oil is 83.5%, the mass percentage of asphaltene is <0.1%, the residual carbon is 5.8%, and the content of metal (Ni+V) is 10.2 μg / g.

[0062] The extracted oil enters the catalytic cracking unit. The process conditions are: reaction temperature 530°C, agent-to-oil ratio 8, water-to-oil ratio 0.05, reaction time 2.5s. The distribution of the obtained products is shown in Table 2. The spent agent obtained after the catalytic cracking reaction enters the first regenerator for oxygen-poor regeneration. The process conditions are: the temperature in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com