Cane molasses pretreatment process and DHA fermentation and production process

A sugarcane molasses and process technology, which is applied in the pretreatment process of sugarcane molasses and the process field of fermenting and producing DHA, can solve the problems of cytotoxicity, poor fluidity of fermentation liquid, difficulty in conducting oxygen, heat and nutrients, etc., and achieve low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

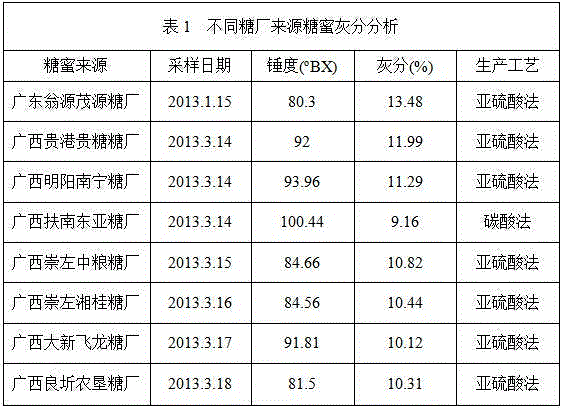

[0037] 1) Pre-treatment of sugarcane molasses:

[0038] Using molasses from Daxin Feilong Sugar Factory in Guangxi as the raw material for fermentation experiments, dilute the molasses with distilled water to a Brix of 50 o BX, add concentrated sulfuric acid to adjust the pH to 2, heat in a water bath at 70°C for 60 minutes, fully hydrolyze the sucrose into reducing sugar, add milk of lime to adjust the pH to 7.0 when the temperature of the sugar liquid drops to 65°C, keep it warm for 30 minutes to flocculate impurities, and add polyacrylamide 3mg / L , keep warm for 10min for secondary flocculation, centrifuge at 8000r / min for 10min, and take the supernatant for later use. The sucrose in the treated supernatant was basically decomposed into reducing sugars, and most of the colloids in the molasses were removed. The potassium ion removal rate in the molasses was 50%, and the calcium ion content was slightly reduced.

[0039] 2) Prepare medium:

[0040] Prepare ordinary see...

Embodiment 2

[0050] 1) Pre-treatment of sugarcane molasses:

[0051] Using molasses from Daxin Feilong Sugar Factory in Guangxi as the raw material for fermentation experiments, dilute the molasses with distilled water to a Brix of 65 o BX, add concentrated sulfuric acid to adjust the pH to 4, heat in a water bath at 95°C for 50 minutes to fully hydrolyze the sucrose into reducing sugar, add milk of lime to adjust the pH to 7.0 when the temperature of the sugar solution drops to 75°C, keep it warm for 30 minutes to flocculate impurities, add polyacrylamide 3mg / L, Incubate for 10 minutes for secondary flocculation, centrifuge at 8000r / min for 10 minutes, and take the supernatant for later use. Sucrose in the treated supernatant is basically decomposed into reducing sugar, wherein the proportion of sucrose is 3.3%, and the proportion of reducing sugar is 46.7%. Most of the colloids in the molasses have been removed, and the removal rate of potassium ions in the molasses is 53%, and the calci...

Embodiment 3

[0064] 1) Pre-treatment of sugarcane molasses:

[0065] The molasses of Guangdong Wengyuan Maoyuan Sugar Factory was used as the raw material for the fermentation experiment, and the molasses was diluted with distilled water to a Brix of 55 o BX, add concentrated sulfuric acid to adjust the pH to 2, heat in a water bath at 95°C for 30 minutes to fully hydrolyze the sucrose into reducing sugar, add milk of lime to adjust the pH to 7.0 when the temperature of the sugar solution drops to 75°C, keep it warm for 30 minutes to flocculate impurities, add polyacrylamide 3mg / L, Incubate for 10 minutes for secondary flocculation, centrifuge at 8000r / min for 10 minutes, and take the supernatant for later use.

[0066] The results are shown in Table 4:

[0067]

[0068] The results in Table 4 show that the sucrose in the treated supernatant was basically decomposed into reducing sugars, and most of the colloids in the molasses were removed. The removal rate of potassium ions in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com