Screw drill stator made of PTFE (Polytetrafluoroethylene) and PTFE applied to stator

A technology of screw drilling tools and PTFE, which is applied in earthwork drilling, drilling equipment, driving devices for drilling in boreholes, etc. It can solve problems such as rubber damage, rubber bushing aging, and excess processing residues, and reduce the friction coefficient. and linear expansion coefficient, improved heat resistance and wear resistance, and excellent dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of PTFE that is applied to screw drilling tool stator, comprises PTFE and additive, and described additive comprises polyether ether ketone powder, carbon fiber, glass fiber and graphite, and wherein, described each component composition (by mass percentage) is : Polyether ether ketone powder: 5%, carbon fiber: 5%, glass fiber: 10%, graphite: 8%, the balance is polytetrafluoroethylene powder. The particle size of the 50% graphite is 70 μm, and the particle size of the 50% graphite is 40 nm. Both the carbon fiber and the glass fiber have a diameter of 15 μm and an aspect ratio of 150:1.

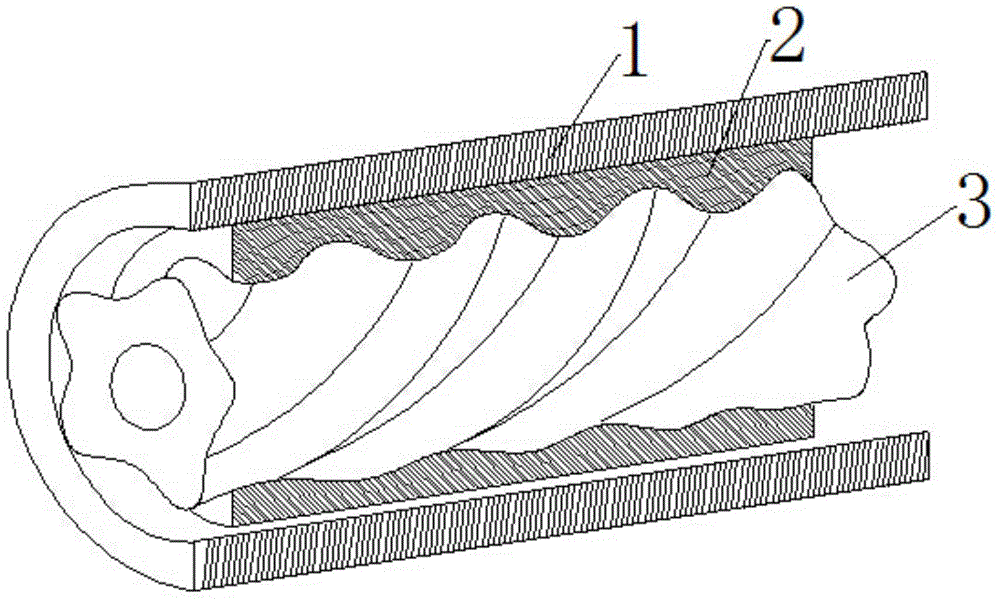

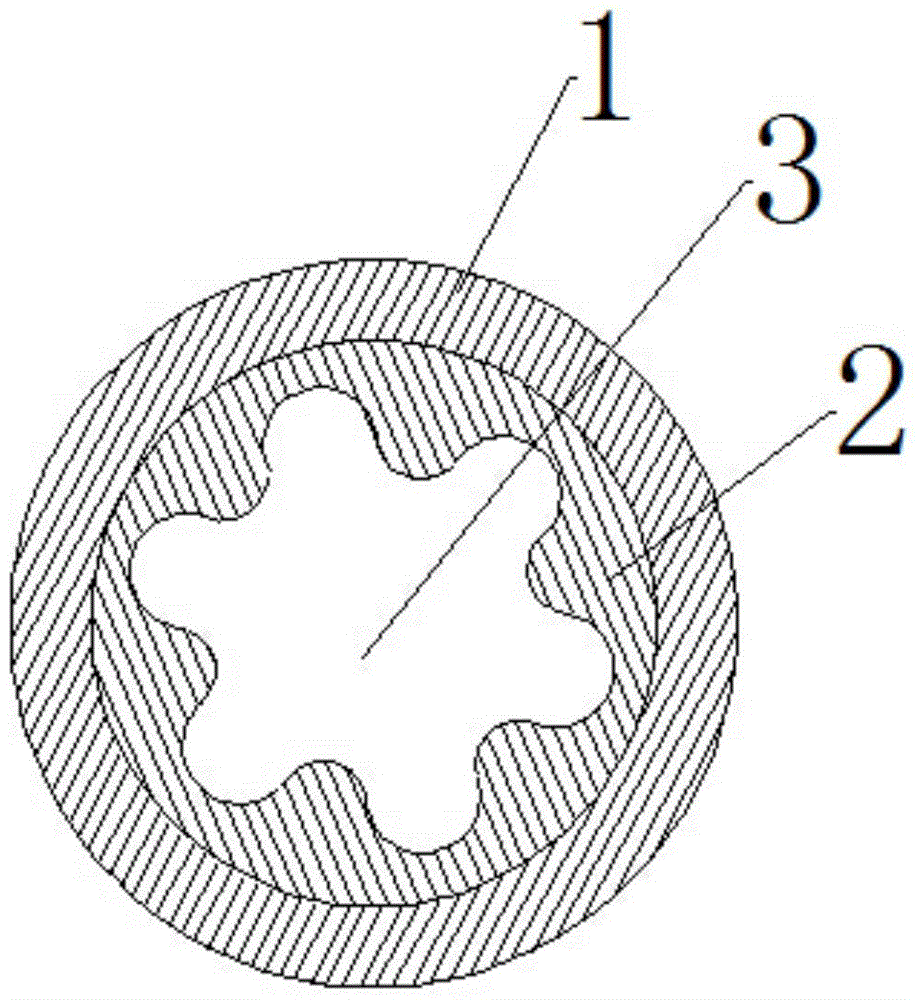

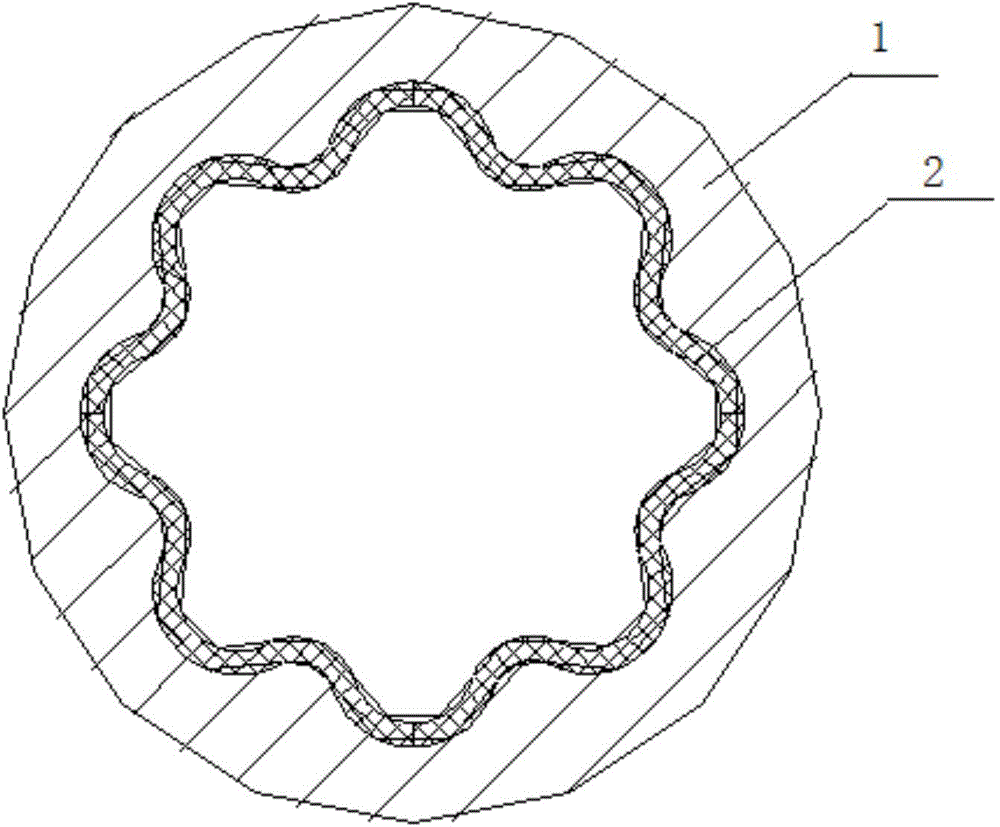

[0035] When the above-mentioned PTFE is used to make the stator of the screw drilling tool, PTFE, polyetheretherketone powder, carbon fiber, glass fiber, and graphite are mixed uniformly by a high-speed kneading machine, and then smelted and extruded to be granulated into powder, and then extruded or Injection molding or molding to obtain one of the application structures such a...

Embodiment 2

[0037] A kind of PTFE that is applied to screw drilling tool stator, comprises PTFE and additive, and described additive comprises polyether ether ketone powder, carbon fiber, glass fiber and graphite, and wherein, described each component composition (by mass percentage) is : Polyether ether ketone powder: 8%, carbon fiber: 8%, glass fiber: 15%, graphite: 8%, the balance is polytetrafluoroethylene powder. The particle size of the 45% graphite is 75 μm, and the particle size of the 55% graphite is 35 nm. Both the carbon fiber and the glass fiber have a diameter of 12 μm and an aspect ratio of 180:1.

[0038] When the above-mentioned PTFE is used to make the stator of the screw drilling tool, PTFE, polyetheretherketone powder, carbon fiber, glass fiber, and graphite are mixed uniformly by a high-speed kneading machine, and then smelted and extruded to be granulated into powder, and then extruded or Injection molding or molding to obtain one of the application structures such a...

Embodiment 3

[0040] A kind of PTFE that is applied to screw drilling tool stator, comprises PTFE and additive, and described additive comprises polyether ether ketone powder, carbon fiber, glass fiber and graphite, and wherein, described each component composition (by mass percentage) is : Polyether ether ketone powder: 6%, carbon fiber: 8%, glass fiber: 12%, graphite: 5%, the balance is polytetrafluoroethylene powder. The particle size of the 55% graphite is 65 μm, and the particle size of the 45% graphite is 45 nm. Both the carbon fiber and the glass fiber have a diameter of 18 μm and an aspect ratio of 120:1.

[0041] When the above-mentioned PTFE is used to make the stator of the screw drilling tool, PTFE, polyetheretherketone powder, carbon fiber, glass fiber, and graphite are mixed uniformly by a high-speed kneading machine, and then smelted and extruded to be granulated into powder, and then extruded or Injection molding or molding to obtain one of the application structures such a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com