System and method for treating hazardous wastes on the basis of plasma smelting furnace

A technology of hazardous waste and flue gas treatment system, which is applied in the field of hazardous waste treatment and environmental protection to avoid secondary pollution and realize recovery and reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

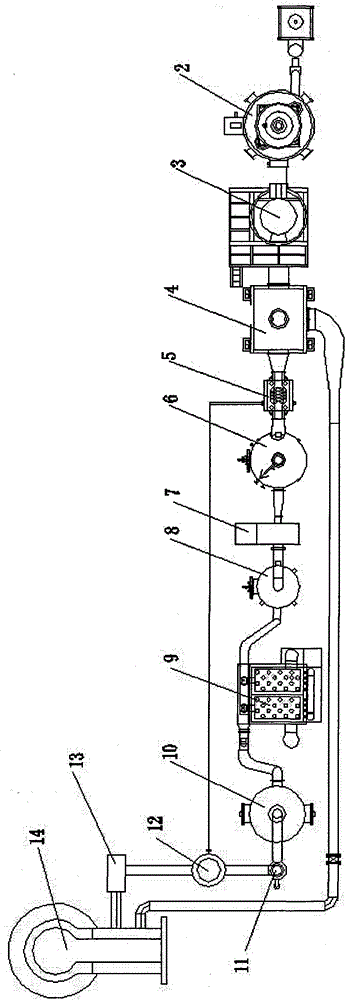

[0025] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

[0026] Such as figure 1 As shown, a hazardous waste treatment system based on a plasma melting furnace includes a pretreatment system, a pyrolysis melting system, and a flue gas treatment system;

[0027] The pyrolysis melting system comprises a plasma melting furnace 2;

[0028] The flue gas treatment system sequentially includes a secondary combustion chamber 3, a gravity settling chamber 4, a quench tower 6, an SCR system 7, a bag filter 9, an activated carbon adsorption tower 10, an alkali washing tower 11, and a smoke stack 14. Chamber 3 is connected to the plasma melting furnace, the gravity settling chamber 4 is connected to the secondary combustion chamber 3 of the pyrolysis melting system, there is also a waste heat boiler 5 betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com