Purification method and apparatus for nuclear power spent fuel pool water and treatment method and apparatus for spent fuel pool water

A purification device and spent fuel pool technology, applied in water/sewage treatment, water/sludge/sewage treatment, ion exchange water/sewage treatment, etc., can solve problems such as uselessness, reduce load, reduce production, The effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

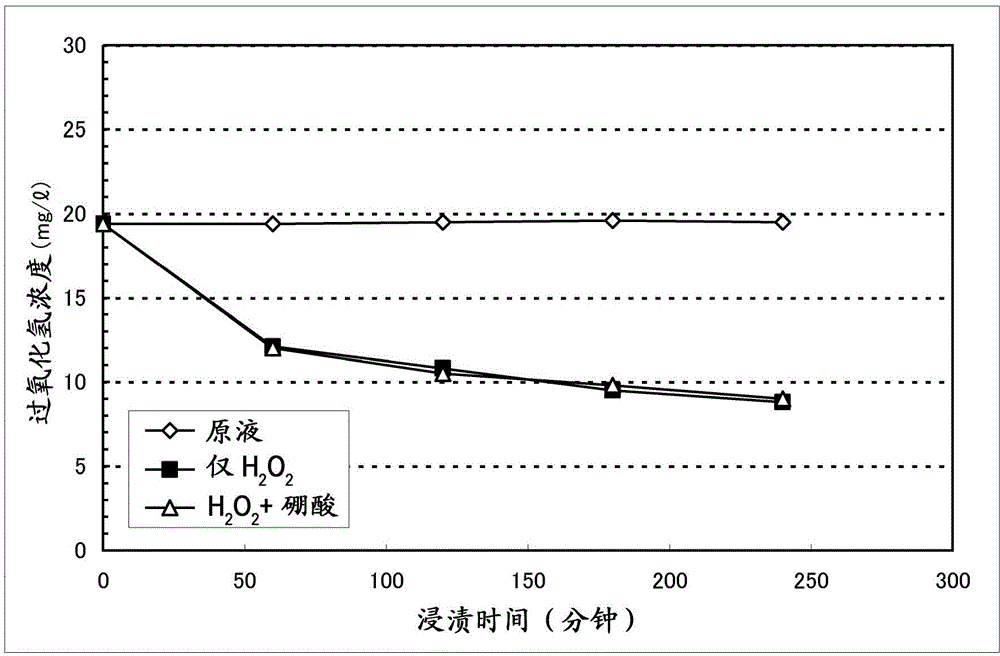

[0037] Use a metal-supported resin, and confirm the hydrogen peroxide decomposition ability by dipping test.

[0038]First, as the metal-supported resin, Pd-supported resin Lewatit (registered trademark) K7333 of LANXESS was used. In the 200ml beaker, add 100ml that has dissolved 20mg / L hydrogen peroxide water and dissolved boric acid so that its concentration is the treated liquid (sample 1) of 2800mg / L (in terms of B concentration), drop into 1ml Pd load resin, measure the time-lapse concentration of hydrogen peroxide. It should be noted that the hydrogen peroxide concentration and the boron concentration are numerical values simulating the water quality of fuel pool water in a pressurized water type (PWR) nuclear power plant. As a reference, the same test was carried out using a liquid to be treated (sample 2) to which no boric acid was added, that is, water to which only hydrogen peroxide was added. The concentration of hydrogen peroxide was calculated by measuring the...

Embodiment 2

[0043] The decomposing ability of hydrogen peroxide was confirmed by a water-through-column test using a metal-supported resin.

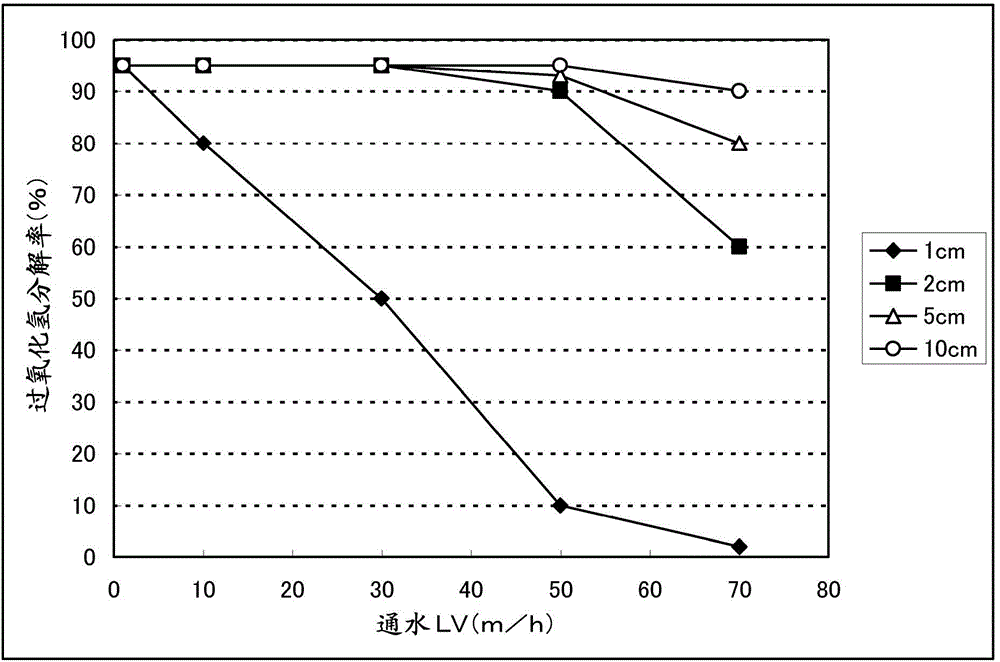

[0044] First, a glass column having an inner diameter of 16 mm was filled with a layer height of 1 to 10 cm using Pd-supporting resin Lewatit (registered trademark) K7333 from LANXESS as the metal-supporting resin. Hydrogen peroxide water adjusted to about 2 mg / L was passed through at a linear velocity LV of 10 to 70 m / h to study the hydrogen peroxide removal performance of the metal-supported resin. The results are shown in Table 2 and image 3 .

[0045] [Table 2]

[0046]

[0047] Depend on image 3 It can be seen that more than 90% of hydrogen peroxide can be decomposed if the layer height is 2 cm or more and the water flow LV is 50 m / h or less.

Embodiment 3

[0049] The influence on the degradation of the ion exchange resin by hydrogen peroxide was confirmed.

[0050] The cationic resin was immersed in solutions of various hydrogen peroxide concentrations for 24 hours, and the total organic carbon (TOC) concentration was measured with TOC-V manufactured by Shimadzu Corporation. Such as Figure 4 As shown, it was confirmed that if the concentration of hydrogen peroxide is less than 1 ppm, there is little influence on resin deterioration. Therefore, it is considered that it is sufficient to decompose 90% or more of the hydrogen peroxide present in the fuel pool at the level of several ppm.

[0051] Generally, if the TOC concentration exceeds 20 ppm, ion exchange resin replacement is performed. Depend on Figure 4 It can be seen that when the hydrogen peroxide concentration exceeds about 3.5 ppm, the TOC concentration exceeds 20 ppm, and the ion exchange resin must be replaced. Depend on figure 2 and Figure 4 It can be seen th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com