A kind of preparation method of iron-nickel-molybdenum magnetic powder core with high magnetic permeability

A high permeability, iron-nickel-molybdenum technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problem of not being able to prepare high-permeability iron-nickel-molybdenum magnetic powder cores, and achieve high permeability and high Effect of Density Permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take water atomized iron nickel molybdenum powder 200 mesh - 300 mesh is 100g, more than 300 mesh is 900g, after mixing for 5 minutes evenly put the iron nickel molybdenum powder into the temperature controllable stirring pot; first add 10ml of 0.05% chromic acid aqueous solution, then add Add 10ml of 0.05% phosphoric acid aqueous solution, add 80ml of water, and keep stirring for 30 minutes; then raise the temperature of the stirring pot to 150°C, stir and dry; after drying, add 100ml of potassium water glass aqueous solution with a mass fraction of 0.1%, and continue stirring until Dry until the iron-nickel-molybdenum powder is cooled, add 100ml of acetone solution with a mass fraction of 0.1%, stir for 30 minutes, take out the iron-nickel-molybdenum powder until it is dry; add 0.3% aluminum stearate after the iron-nickel-molybdenum powder is dry As lubricating powder, after stirring evenly, use 18 tons / cm 2 The pressure is pressed into a standard magnetic ring with a...

Embodiment 2

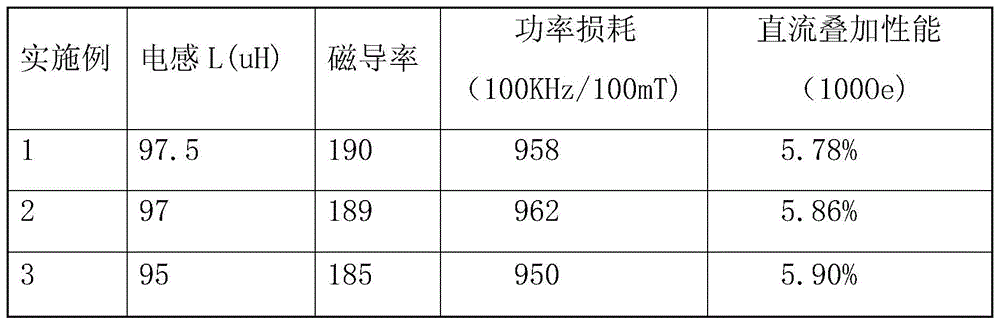

[0028] The preparation method of the iron-nickel-molybdenum magnetic powder core is the same as in Example 1, except that the potassium water glass in the formula of Example 1 is changed into water glass, and all the other technological processes are the same, and the product is prepared, and the test conditions are the same as in Example 1. The test results are shown in Table 1.

Embodiment 3

[0030] The preparation method of the iron-nickel-molybdenum magnetic powder core is the same as in Example 1, except that the aluminum stearate in the formula of Example 1 is changed to zinc stearate as a lubricant, and the rest of the process is the same, and the product is prepared, and the test conditions are the same as in Example 1. . The test results are shown in Table 1.

[0031] Table 1

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| core loss | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com