Process for recovering cobalt chloride from waste lithium ion battery

A lithium-ion battery and cobalt chloride technology, applied in battery recycling, waste collector recycling, cobalt halide, etc., can solve problems such as waste of resources, and achieve the effects of convenient use, simple operation process, and rational utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

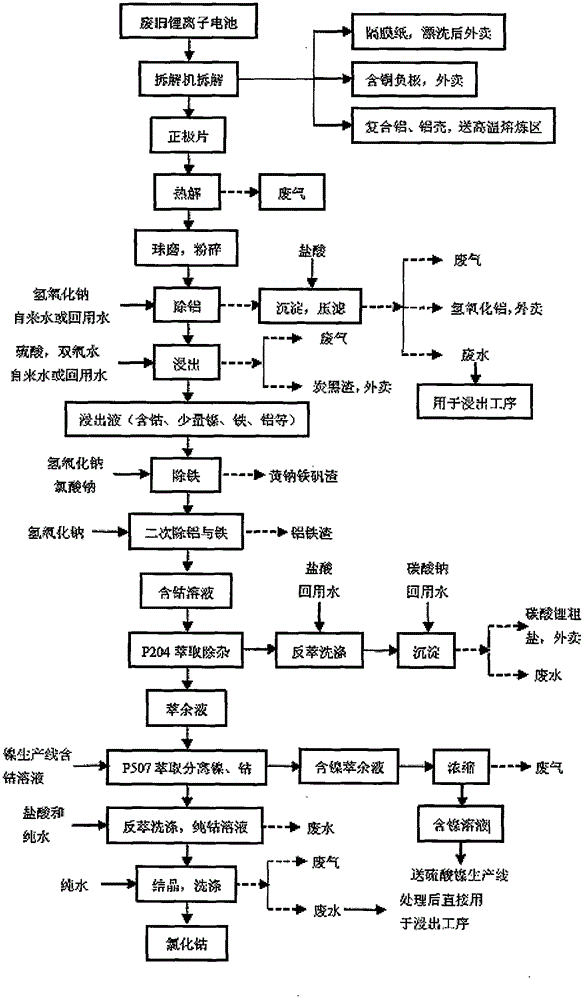

[0019] see figure 1 , the process flow chart of the process of recovering cobalt chloride from waste lithium-ion batteries, the waste lithium-ion batteries are disassembled by a dismantling machine, and the positive electrode sheet, diaphragm paper, copper-containing negative electrode, and aluminum shell are separated; the positive electrode sheet is in Carry out pyrolysis at a high temperature of 500-600°C; put the pyrolyzed positive electrode sheet in a ball mill for ball milling, and control the ball milling particle size to -100 mesh to account for 50%; add sodium hydroxide to the ball-milled positive electrode sheet to obtain The precipitated matter is filtered out, and press-filtered, then add 1-3mol / l hydrochloric acid solution to react ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com