Method for simultaneously preparing biosorbent and flocculant for heavy metal adsorption and product thereof

A biosorbent and heavy metal technology, applied in the field of environmental engineering, can solve the problems of difficult flocculants, high price, and unsuitable chemical toxicity, etc., and achieve the effects of strong adsorption capacity of heavy metals, reduced production costs, and excellent reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Acclimatization of Thiobacillus ferrooxidans with high concentration of aluminum ions: Add Al to 200mL 9K medium 2 (SO 4 ) 3 .18H 2 O, its concentration increased from the initial 7.5g to 15g, 22.5g, 30g in turn, passed three times at the concentration of 30g, the initial pH was 2.0, the temperature was 30°C, and the shaker speed was 180rpm, finally obtained in the presence of high concentrations of aluminum ions. A strain of Thiobacillus ferrooxidans with stable ferrous oxidation ability;

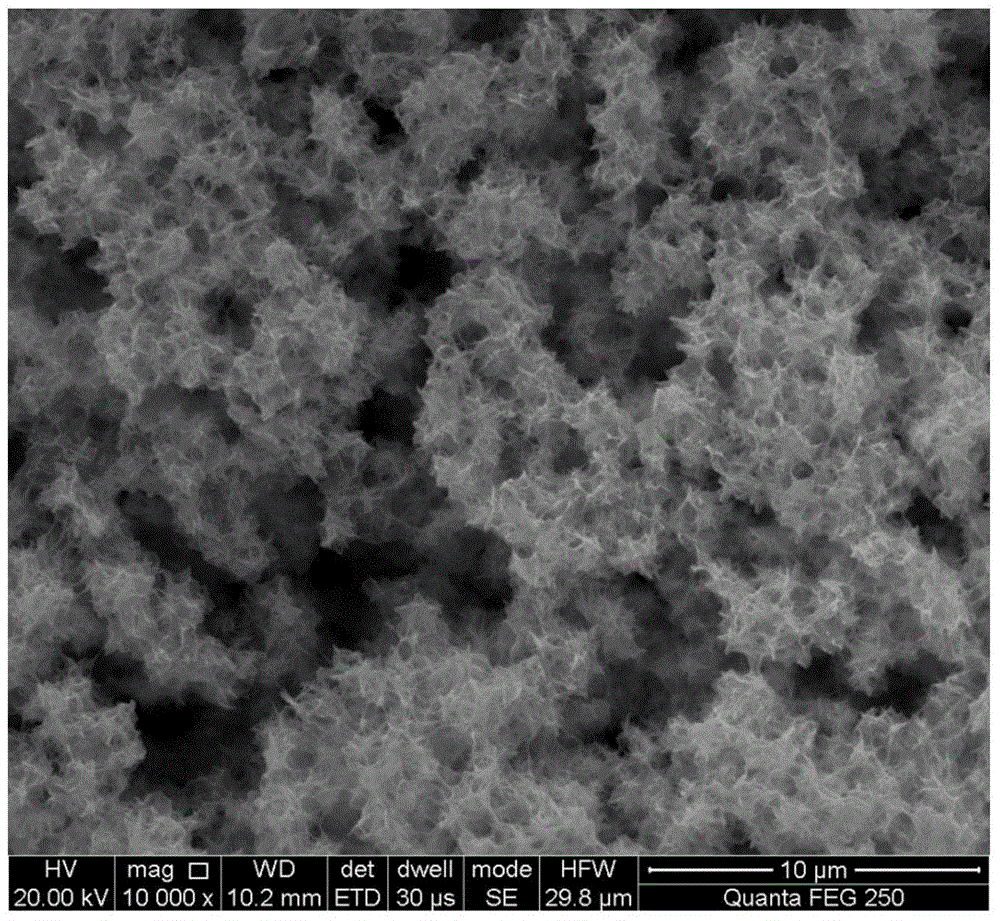

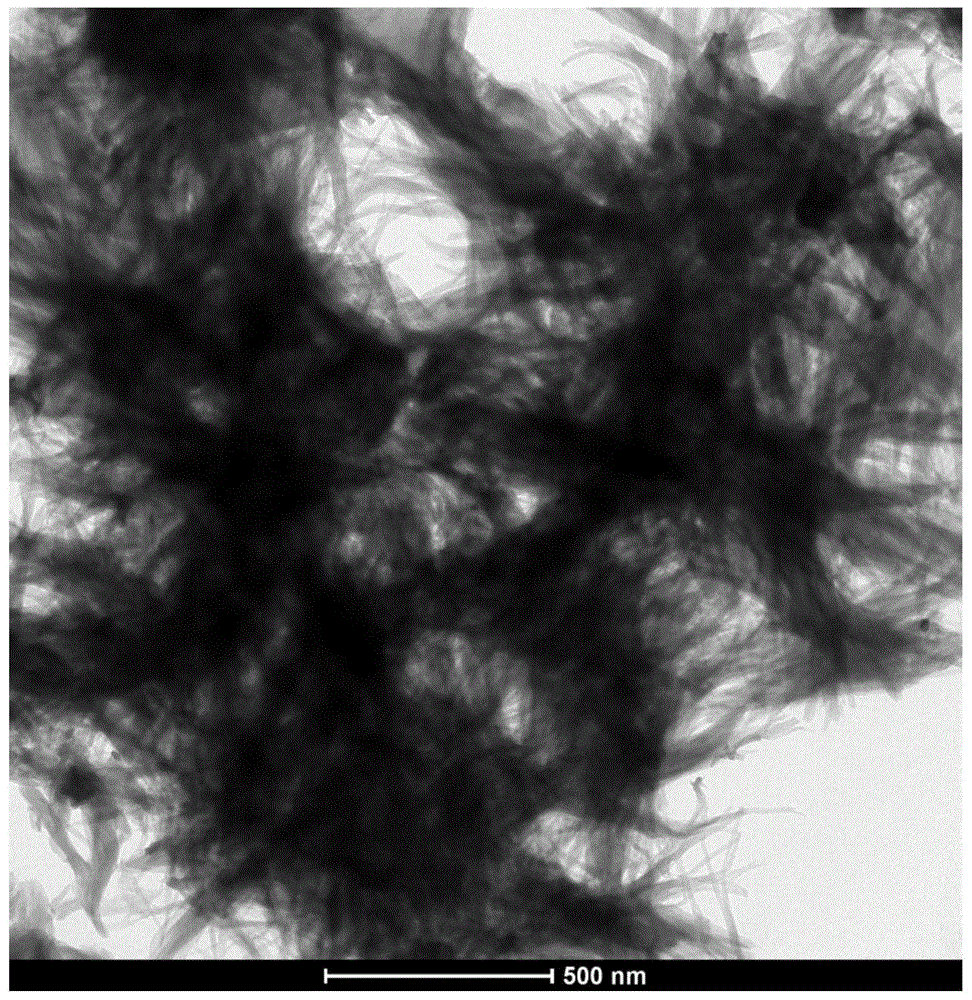

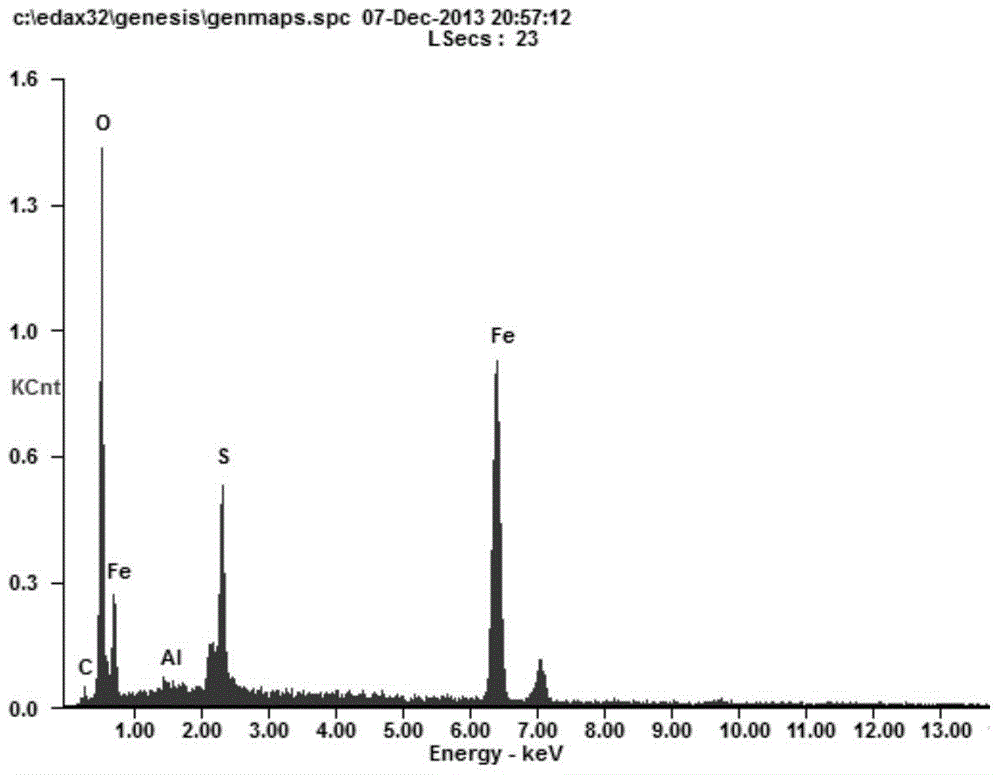

[0030] (2) Thiobacillus ferrooxidans expanded cultivation: the Thiobacillus ferrooxidans that step (1) domesticates obtains, is added with 30g Al by 500 shake flasks 2 (SO 4 ) 3 .18H 2 In the 9K medium of O, expand the culture, and filter through 0.45um filter paper when its proliferation enters the end of algebraic growth (about 5 days), remove the precipitate, obtain the filtrate, and collect the thalline by centrifugation at 12,000 in a high-speed refrigerated centrifug...

Embodiment 2

[0035] 1. Preparation of polymeric sodium silicate: take 4.73g of Na 2 SiO 3 9H 2 O sodium silicate was dissolved in 50mL distilled water to make silica SiO 2 The concentration is 2%, and the initial pH is 12.5-13.0 at this time, then slowly add 10% sulfuric acid dropwise to the solution while stirring, adjust the pH of the polymeric sodium silicate to 2.0, and let it stand at 30°C for 90 minutes.

[0036] 2. Compound the polyaluminum ferric sulfate filtrate described in step (3) in the preparation process of the iron-based heavy metal adsorption material in Example 1 and polysodium silicate at a ratio of 1:1, mix them evenly, adjust the pH value to 1.5, and stir 30min, react in a water bath at 60°C for 120min, shake evenly 60 times / min during the period, and stand still to obtain a brown-red polysilicon-aluminum ferric sulfate flocculant.

[0037] 3. Take 100uL, 200uL, 500uL, 800uL, and 1mL of composite flocculant and add it to 100mL, 5% kaolin suspension, stir rapidly at ...

Embodiment 3

[0040] 1. Take 400mL of artificial lake water, the water body is light green, the water temperature is 20°C, the pH is 6.83, and the COD is 412mg / L. Add copper sulfate to it to make the copper ion concentration reach 100mg / L, and configure it as high COD wastewater polluted by heavy metals.

[0041] 2. Add 2mL of the 1:1 compound flocculant prepared in Example 2 and 1g of the adsorbent prepared in Example 1 to the simulated wastewater, stir at 200rpm for 2min, let stand for 5min, take a sample at 2cm below the liquid surface, and pass through a microplate reader The concentration of copper ions was measured at 600nm, and the COD content was measured by a TOC analyzer.

[0042] Conclusion: After treatment, the concentration of copper ions in the lake water was 12.3 mg / L, and the COD content was reduced to 62.77 mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com