Composite sheet structure for decoration and preparation method of composite sheet structure

A composite sheet and sheet technology, applied in chemical instruments and methods, lamination devices, synthetic resin layered products, etc., can solve the problems of scratch resistance, easy deformation, migration of small molecules, etc., and achieve a bright surface. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

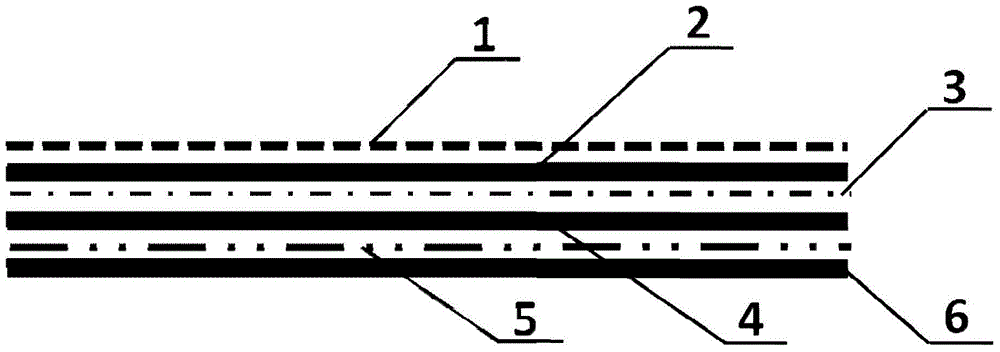

[0040] The preparation method and process of the composite sheet are as follows in sequence: polyester film hardening treatment→preparation of polyester precoat film→sticking treatment of polyester precoat film→polyester precoat film and PVC sheet hot-compression compounding. The specific process is as follows:

[0041] 1. Polyester film hardening treatment

[0042] The polyester film layer (2) is a biaxially oriented polyester film (BOPET) with a thickness of 25-150 μm, prepared through a biaxially oriented production line or purchased from polyester film manufacturers such as Tianjin Wanhua and Foshan Dupont. The surface hardened layer (1) is a UV photocurable resin coating, the surface hardness of which is above 2H, and the thickness is 5-15 μm. The composition ratio is: acrylate monomer 75%-85%, reactive diluent 5%-10%, photoinitiator 5%-8%, other additives 1%-2% (including leveling agent, defoamer and wetting agents, etc.). Firstly, the polyester film base material is un...

Embodiment 1

[0050] 1. Polyester film hardening treatment

[0051] First, the BOPET substrate of 25μm×1500mm×6000m is unwound on the UV coating line and completely flattened, and the oven is raised to the set temperature (70°C) to ensure the coating quality; secondly, 80% acrylate monomer , 10% reactive diluent, 8% photoinitiator, 0.5% leveling agent and 1.5% wetting agent are mixed evenly and transferred to the glue tank of the UV coating production line; finally, turn on the UV lamp and adjust the UV power to 400mJ / cm2, the polyester film is gravure coated and rolled, so as to obtain a 1500mm × 6000m polyester film with a hardened layer of 8 μm.

[0052] 2. Preparation of polyester precoating film

[0053] First, the 33 μm thick hardened polyester film base material is unwound and completely flattened on the extrusion compounding line, and the polyethyleneimine aqueous solution with a solid content of 5% is configured, added to the glue tank, and the oven is raised to the set temperatur...

Embodiment 2

[0060] 1. Polyester film hardening treatment

[0061] Firstly, the 250μm×1300mm×4000m PETG substrate is unwound and completely flattened on the UV coating line, and the oven is raised to the set temperature (70°C) to ensure the coating quality; secondly, 85% acrylate monomer , 18% reactive diluent, 5% photoinitiator, 0.5% leveling agent and 1.5% wetting agent are mixed evenly and transferred to the glue tank of the UV coating production line; finally, turn on the UV lamp and adjust the UV power to 350mJ / cm2, the polyester film is gravure coated and rolled up, so as to obtain a 1300mm * 4000m polyester film with a 10μm hardened layer.

[0062] 2. Preparation of polyester precoating film

[0063] First, the 260 μm thick hardened polyester film base material is unwound and completely flattened on the extrusion compounding line, and the polyethyleneimine aqueous solution with a solid content of 5% is configured, added to the glue tank, and the oven is raised to the set temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com